Electrotome surface laser grooving and polishing integral machining method

A technology of laser grooving and processing methods, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced performance, easy adhesion on the surface, and easy corrosion, so as to improve fluidity, Improve corrosion resistance and performance, improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Take the metal electric knife sample 9 and use alcohol to ultrasonically clean and dry it.

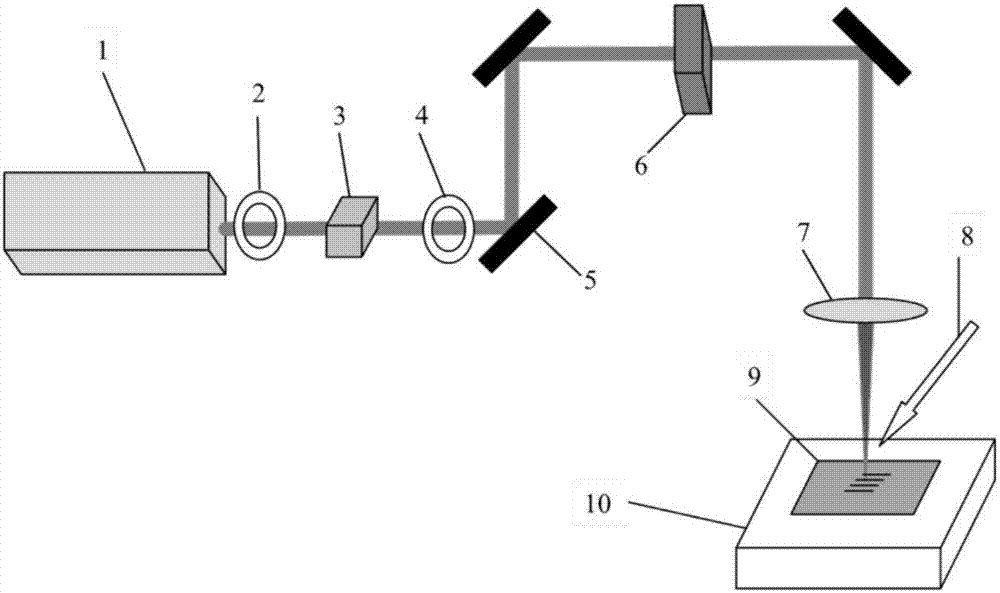

[0029] Step 2. Start the picosecond laser 1 and the supporting software system, set the scanning area to 4mm×15mm, the groove width and spacing to 50μm, and the direction of the groove to be parallel to the direction of the blade. The laser spot diameter is 35μm, the laser wavelength is 193nm, the repetition frequency is 10KHz, the output power is 1W, the laser scanning speed is 10mm / s, and the scanning times are 200 times. During the process, the protective gas argon 8 is passed.

[0030] Step 3. Ultrasonic cleaning of the processed electric knife.

[0031] Step 4. Use a nanosecond pulse laser with a pulse width of 220ns to set a laser scanning area of 6mm×20mm to polish the micro-grooves on the knife surface of the electric knife, and the direction of the grooves is parallel to the scanning direction of the nanosecond laser. The laser spot diameter is 50 μm, the la...

Embodiment 2

[0034] Step 1. is the same as embodiment 1.

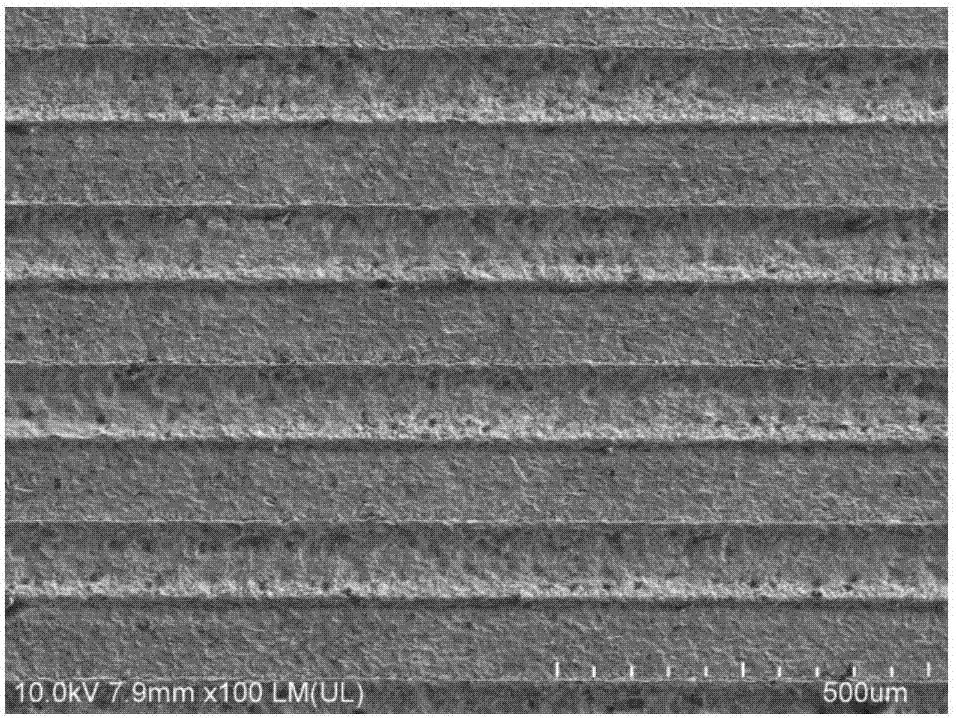

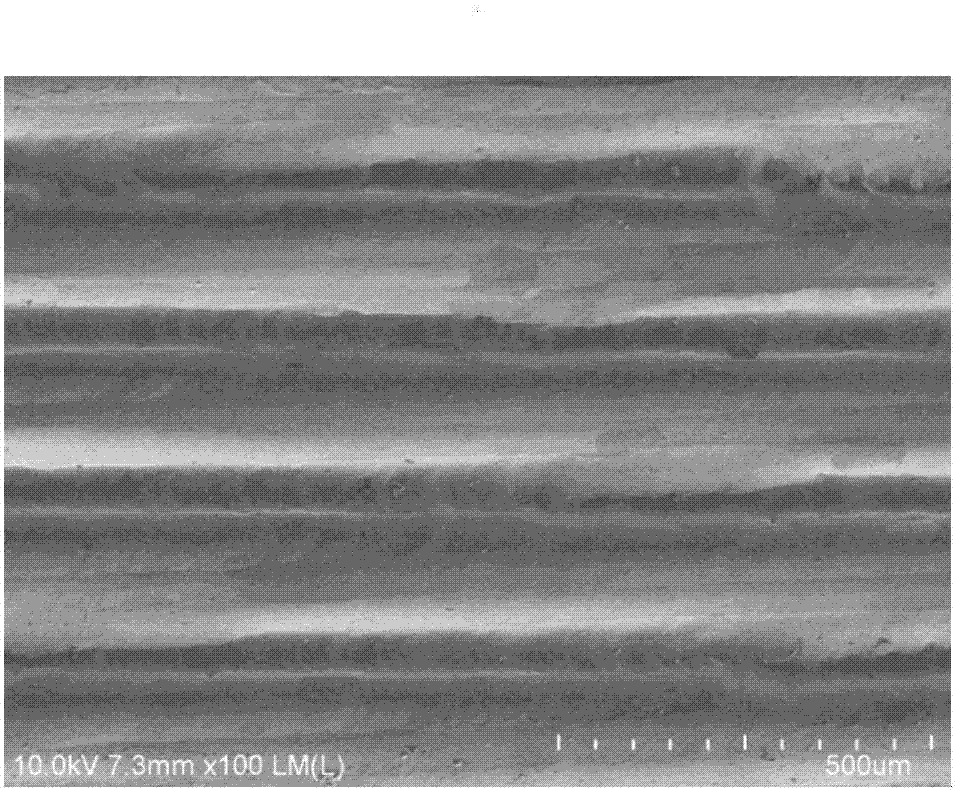

[0035] Step 2. Start the picosecond laser 1 and the supporting software system, set the scanning area to 4mm×15mm, the groove width and spacing to 150μm, and the direction of the groove to be parallel to the direction of the blade. The laser spot diameter is 35μm, the laser wavelength is 532nm, the repetition frequency is 500KHz, the output power is 50W, the laser scanning speed is 500mm / s, and the scanning times are 100 times. During the process, the protective gas argon 8 is passed. The results of preliminary notching are as follows figure 2 As shown, the confocal 3D view is shown as Figure 4 shown.

[0036] Step 3. is the same as embodiment 1.

[0037] Step 4. Use a nanosecond pulse laser with a pulse width of 220ns to set a laser scanning area of 6mm×20mm to polish the micro-grooves on the knife surface of the electric knife, and the direction of the grooves is parallel to the scanning direction of the nanosecond laser....

Embodiment 3

[0040] Step 1. is the same as embodiment 1.

[0041] Step 2. Start the picosecond laser 1 and the supporting software system, set the scanning area to 4mm×15mm, the groove width and spacing to 250μm, and the direction of the groove to be parallel to the direction of the blade. The laser spot diameter is 35μm, the laser wavelength is 1064nm, the repetition frequency is 1000KHz, the output power is 100W, the laser scanning speed is 1000mm / s, and the scanning frequency is 1 time. During the process, the protective gas argon 8 is passed.

[0042] Step 3. is the same as embodiment 1.

[0043]Step 4. Use a nanosecond pulse laser with a pulse width of 220ns to set a laser scanning area of 6mm×20mm to polish the micro-grooves on the knife surface of the electric knife, and the direction of the grooves is parallel to the scanning direction of the nanosecond laser. The laser spot diameter is 50μm, the laser wavelength is 1064nm, the repetition frequency is 1000KHz, the output power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com