Process and equipment for separating salt and nitrate without industrial wastewater discharge

A technology of industrial wastewater and zero discharge, which is applied in the field of salt and nitrate separation process and equipment, can solve the problems that products cannot be reused, affect the progress of enterprise projects, and a large amount of solid waste, so as to meet the requirements of sustainable development, reduce solid waste or The probability of hazardous waste generation and the effect of reducing the dependence on boiler equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

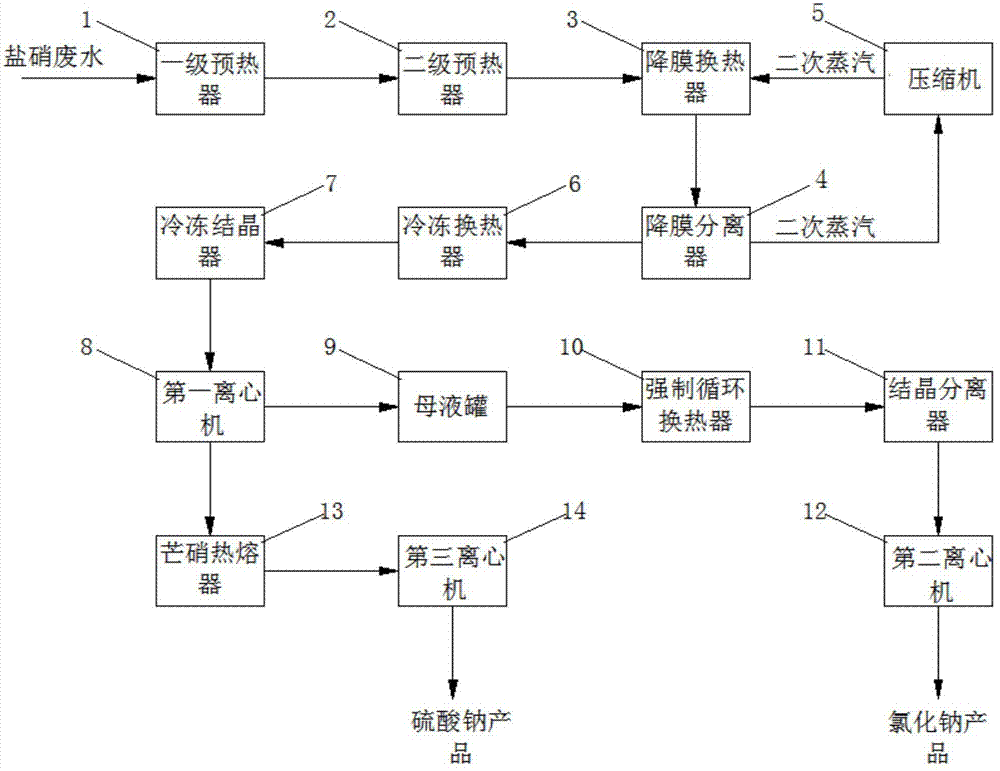

[0031] This embodiment provides a salt and nitrate separation process for zero discharge of industrial wastewater, such as figure 1 As shown, it includes the following steps:

[0032] S1. Preheat the salt-nitrate wastewater containing sodium chloride and sodium sulfate. The salt-nitrate wastewater at normal temperature is preheated twice through the primary preheater 1 and the secondary preheater 2 to reach the bubble point of the wastewater. In the salt nitrate waste water described in the present embodiment, the mass fraction of sodium sulfate is 4.5%, and the mass fraction of sodium chloride is 9.13%, and the flow rate of the waste water is 21t / h. After the heater 2 is preheated twice, the temperature of the wastewater reaches 95°C, reaching the bubble point of the material, and the heat source of the primary preheater 1 comes from the waste heat of distilled water in the recovered system, and the heat source of the secondary preheater 2 is fresh steam. The pressure of the...

Embodiment 2

[0049] This embodiment provides a salt and nitrate separation process with zero discharge of industrial wastewater, as shown in the figure, which includes the following steps:

[0050] S1. Preheat the salt-nitrate wastewater containing sodium chloride and sodium sulfate. The salt-nitrate wastewater at normal temperature is preheated twice through the primary preheater 1 and the secondary preheater 2 to reach the bubble point of the wastewater. In the salt-nitrate wastewater described in this embodiment, the mass fraction of sodium sulfate is 5.36%, the mass fraction of sodium chloride is 8.17%, and the flow rate of the wastewater is 18t / h. After the heater 2 is preheated twice, the temperature of the wastewater reaches 95°C, reaching the bubble point of the material, and the heat source of the primary preheater 1 comes from the waste heat of distilled water in the recovered system, and the heat source of the secondary preheater 2 is fresh steam. The pressure of the fresh steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com