Doped and coated dual-modified lithium/sodium layered metal oxide positive electrode material and one-step synthesis method therefor

A technology of cathode materials and layered metals, applied in the field of lithium/sodium layered metal oxide cathode materials and their one-step synthesis, can solve the problems of low ion diffusion coefficient, poor rate performance, poor thermal stability, etc., and achieve the process method Simple, simple operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Measure 60mL of absolute ethanol and place it in a 200mL beaker, then add 0.0003mol of tetrabutyl titanate and 0.00015mol of lanthanum acetate into the above solution, and transfer the above solution to a 60°C water bath , stirred at a stirring speed of 400rmp until fully dissolved, weighed 0.0324mol of lithium hydroxide (excessive 8% lithium) was added to the solution and stirred until a sol was formed, weighed 0.03mol of Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor was stirred and moved into a blast drying oven, and dried at 120°C for 24 hours. The obtained powder was placed in an agate mortar and ground evenly, then placed in a corundum porcelain boat, and the corundum porcelain boat was transferred to a tube furnace. Calcined at 480°C for 5h and 830°C for 12h under an oxygen atmosphere to obtain titanium doped with 1%, La 4 NiLiO 8 LiNi with an interface coating of 0.125% 0.8 co 0.1 mn 0.1 o 2 Cathode material.

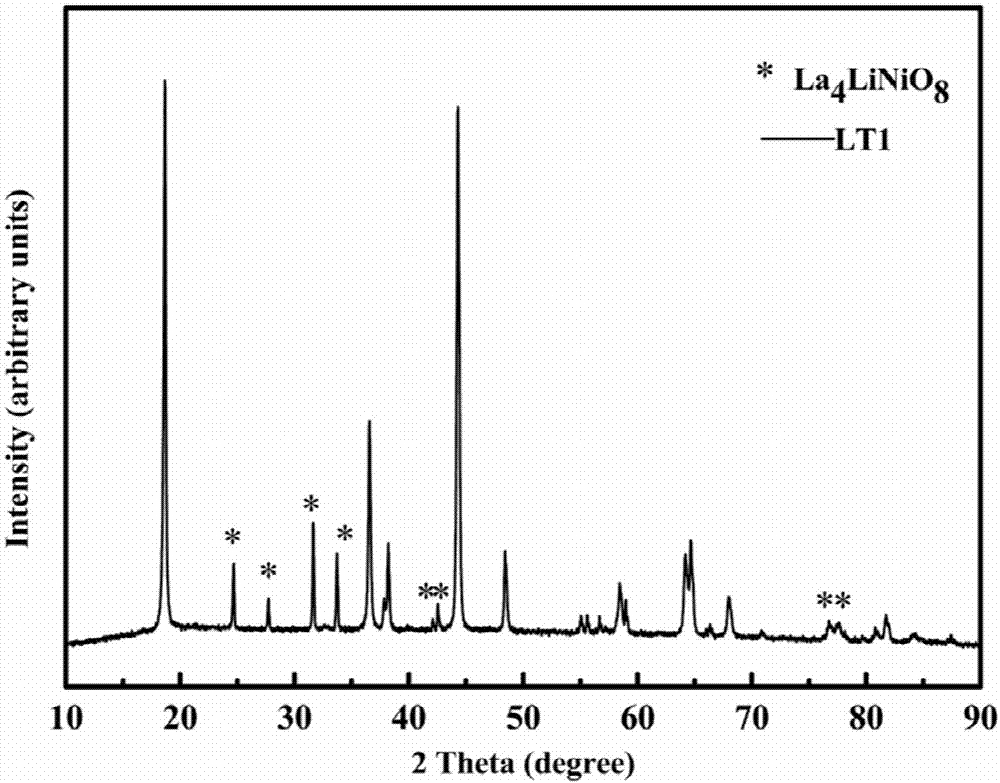

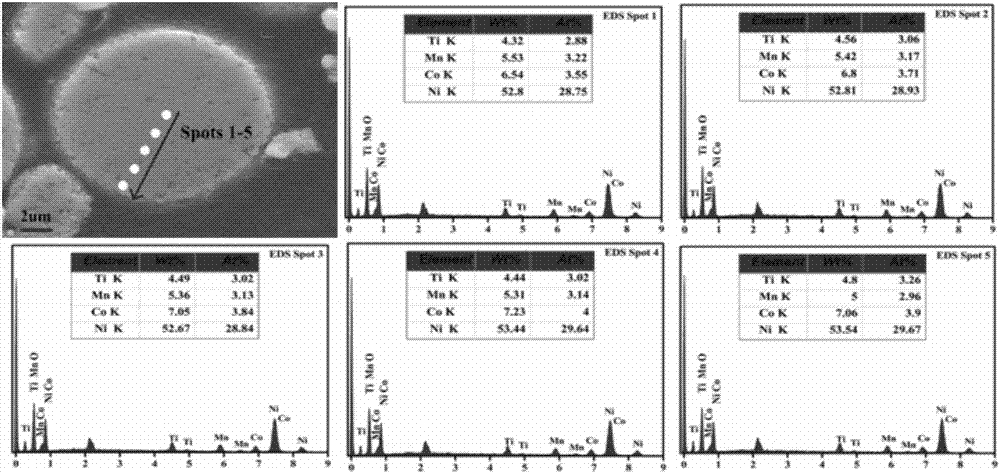

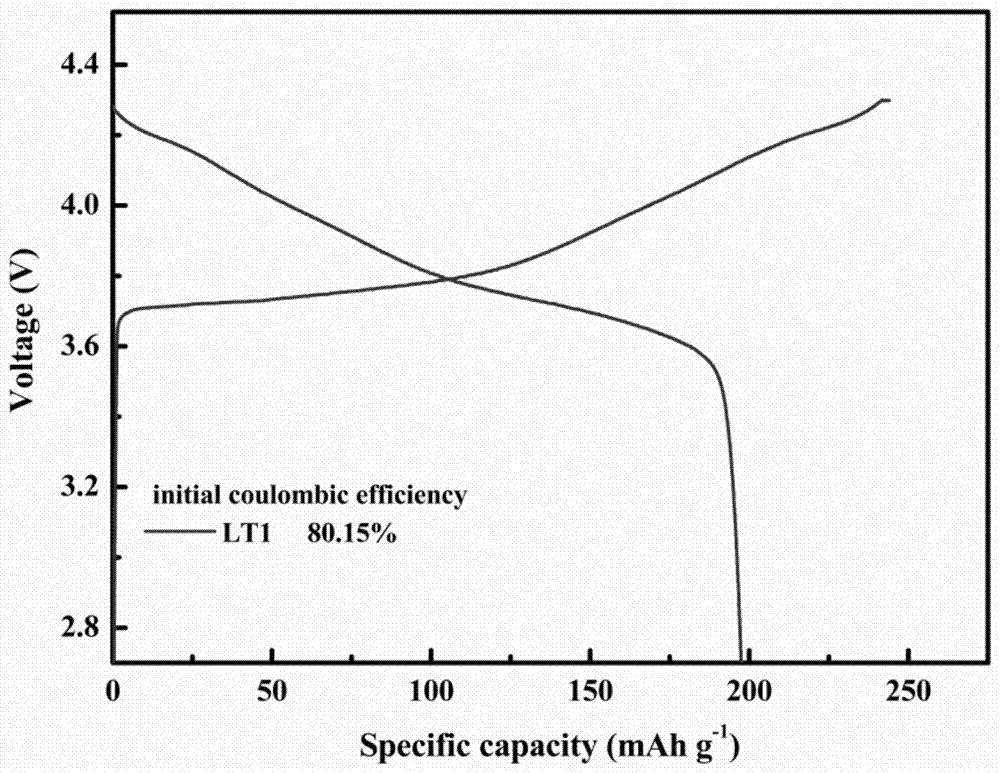

[0034] By XRD analysis (such as figure 1 shown...

Embodiment 2

[0036] Measure 60mL of absolute ethanol and place it in a 200mL beaker, then add 0.0009mol of tetrabutyl titanate and 0.00015mol of lanthanum acetate into the above solution, and transfer the above solution to a 60°C water bath , stirred at a stirring speed of 400rmp until fully dissolved, weighed 0.0324mol of lithium hydroxide (excessive 8% lithium) was added to the solution and stirred until a sol was formed, weighed 0.03mol of Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor was stirred and moved into a blast drying oven, and dried at 120°C for 24 hours. The obtained powder was placed in an agate mortar and ground evenly, then placed in a corundum porcelain boat, and the corundum porcelain boat was transferred to a tube furnace. Calcined at 480°C for 5h and 830°C for 12h under an oxygen atmosphere to obtain titanium doped with 3%, La 4 NiLiO 8 LiNi with an interface coating of 0.125% 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0037] By XRD analysis, it was observed that th...

Embodiment 3

[0039] Measure 60 mL of absolute ethanol and put it in a 200 mL beaker, then add 0.003 mol of tetrabutyl titanate and 0.0015 mol of lanthanum acetate into the above solution, transfer the above solution to a 60°C water bath, Stir at a stirring speed until completely dissolved, weigh 0.0324mol of lithium hydroxide (8% excess lithium) into the solution and stir until a sol is formed, weigh 0.03mol of Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor was stirred and moved into a blast drying oven, and dried at 120°C for 24 hours. The obtained powder was placed in an agate mortar and ground evenly, then placed in a corundum porcelain boat, and the corundum porcelain boat was transferred to a tube furnace. Calcined at 480°C for 5h and 830°C for 12h in an oxygen atmosphere to obtain titanium doped with 10%, La 4 NiLiO 8 The interface coating amount is 1.25% modified LiNi 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0040] By XRD analysis, it was observed that the layered structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com