Indium-doped ordered mesoporous alumina supported noble metal catalyst and application thereof

A precious metal catalyst and alumina-supported technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of high industrial cost, complex system, cumbersome process, etc. problems, achieve high catalytic performance, increase specific surface area, and improve catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

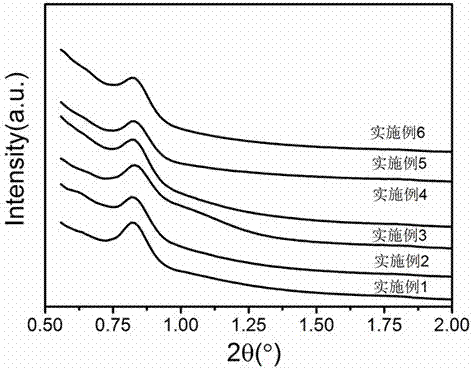

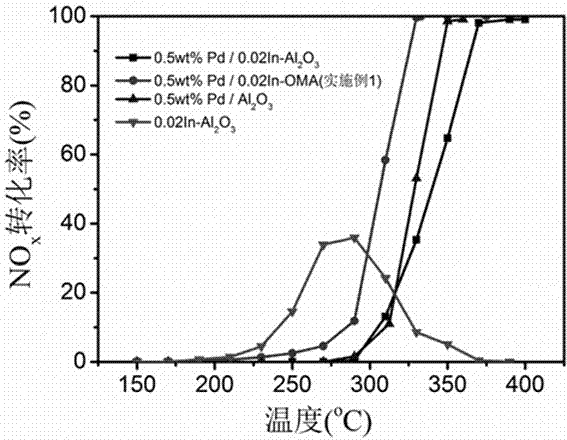

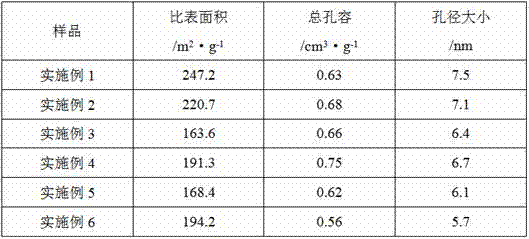

Embodiment 1

[0028] At room temperature, 1.00 g P123 (EO 20 PO 70 EO 20 , EO=ethylene oxide, PO=propylene oxide) was dissolved in a mixed solution of 15 mL of absolute ethanol and 5 mL of isopropanol, and then about 1.00 mL of concentrated nitric acid was added to the system to adjust the pH value to about 6; Add 0.0764g of indium nitrate and keep stirring for 30 min, then slowly add 2.04g of aluminum isopropoxide under constant stirring, and then vigorously stir at 1000 r / min for 10h. The above solution was aged at 60 °C for 10 h to obtain a sol, and then the solvent was evaporated to dryness, and the obtained xerogel was placed in a muffle furnace, and the temperature was raised to 400 °C at a rate of 0.5 °C / min, and after the heat preservation treatment for 4 h, it was heated at 10 °C Continue to heat up to 800°C at a rate of 1 / min, calcine for 2 hours, and cool down naturally to obtain the carrier. Drop 0.5 wt% Pd solution on the carrier by impregnation method (the dropping amount i...

Embodiment 2

[0030] At room temperature, 1.00 g P123 (EO 20 PO 70 EO 20 , EO=ethylene oxide, PO=propylene oxide) was dissolved in a mixed solution of 15 mL of absolute ethanol and 5 mL of isopropanol, and then about 1.00 mL of concentrated nitric acid was added to the system to adjust the pH value to about 6; Add 0.1528g of indium nitrate and keep stirring for 30 min, then slowly add 2.04g of aluminum isopropoxide under constant stirring, and then vigorously stir at 1000 r / min for 10h. The above solution was aged at 60 °C for 10 h to obtain a sol, and then the solvent was evaporated to dryness, and the obtained xerogel was placed in a muffle furnace, and the temperature was raised to 400 °C at a rate of 0.5 °C / min, and after the heat preservation treatment for 4 h, it was heated at 10 °C Continue to heat up to 800°C at a rate of 1 / min, calcine for 2 hours, and cool down naturally to obtain the carrier. Drop 0.5 wt% Pd solution on the carrier by impregnation method (the dropping amount i...

Embodiment 3

[0032] At room temperature, 1.00 g P123 (EO 20 PO 70 EO 20 , EO=ethylene oxide, PO=propylene oxide) was dissolved in a mixed solution of 15 mL of absolute ethanol and 5 mL of isopropanol, and then about 1.00 mL of concentrated nitric acid was added to the system to adjust the pH value to about 6; Add 0.2292g of indium nitrate and keep stirring for 30 min, then slowly add 2.04g of aluminum isopropoxide under constant stirring, and then vigorously stir at 1000 r / min for 10h. The above solution was aged at 60 °C for 10 h to obtain a sol, and then the solvent was evaporated to dryness, and the obtained xerogel was placed in a muffle furnace and raised to 400 °C at a rate of 0.5 °C / min. Continue to heat up to 800°C at a rate of 1 / min, calcine for 2 hours, and cool down naturally to obtain the carrier. Drop 0.5 wt% Pd solution on the carrier by impregnation method (the dropping amount is calculated by adding 0.005 grams of metal Pd per gram of carrier), put it into a muffle furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com