Laser transmission welding method of transparent thin glass

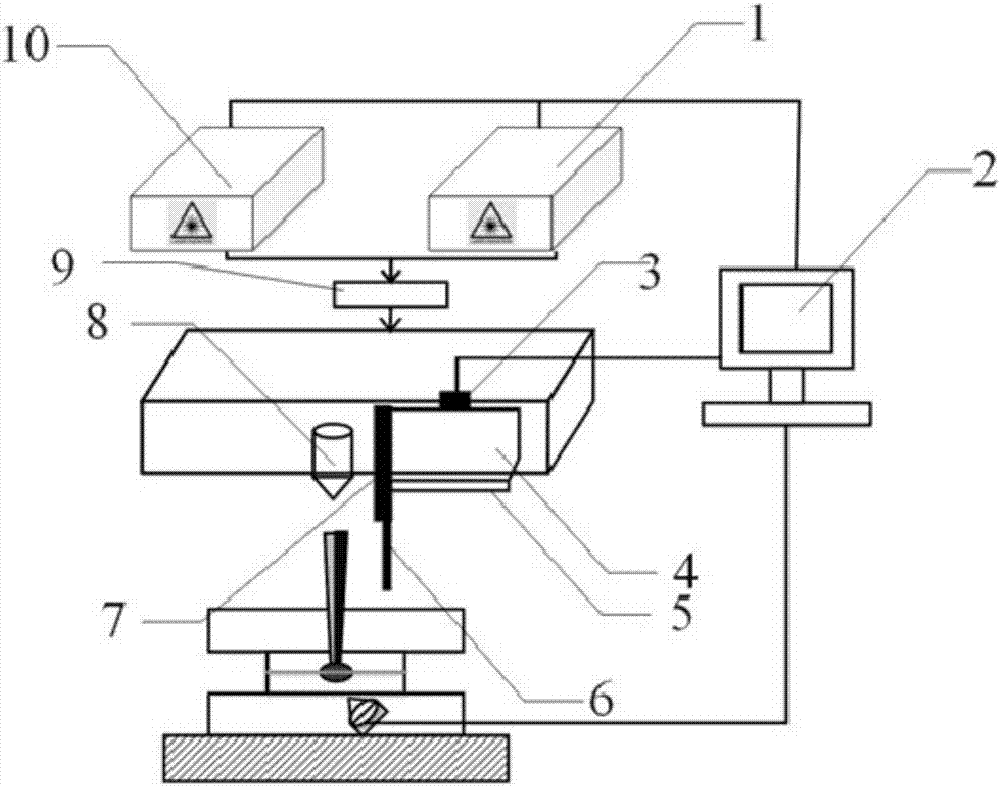

A technology of laser transmission welding and thin glass, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of lack of temperature and weld quality feedback closed-loop control, low heating efficiency of halogen lamps, and low welding efficiency To achieve the effect of realizing online detection and monitoring of molten pool temperature, improving welding efficiency and welding quality, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

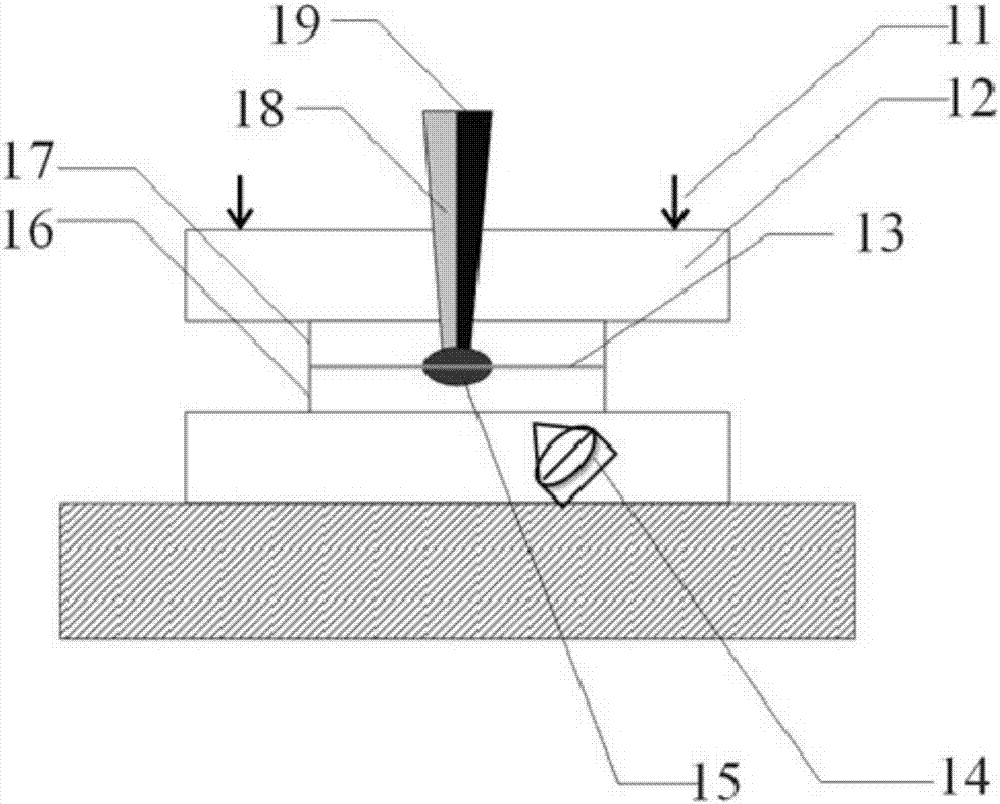

[0033] Specific embodiment: choose two kinds of lasers that can pass through the transparent glass to be welded, one is an ultraviolet wavelength laser beam 18 with a wavelength of 325-400nm, and the other is an infrared wavelength laser beam 19 with a wavelength of 900-1064nm.

[0034] The material of the upper glass 17 and the lower glass 16 is high borosilicate glass, the size is 20mm×50mm, the thickness is 2000±20μm, and the overlapping surface area of the upper glass 17 and the lower glass 16 is 20mm×20mm. The upper glass 17 and the lower glass 16 were ultrasonically cleaned with ethanol for 10 minutes to remove surface impurities, and then placed in a drying oven to dry for 12 hours. After the drying is completed, use a magnetron sputtering apparatus to coat a layer of titanium film 13 on the upper surface of the lower glass 16, the thickness of the titanium film is 200-300nm;

[0035] The treated upper glass 17 overlaps the upper surface coated with the titanium film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com