Ramming material for blast furnace trough

A blast furnace tapping and ramming material technology, applied in the field of unshaped refractories, can solve the problems of ramming material bursting structure, damage to workers' health, affecting structural strength, etc., achieve large bulk density, improve normal temperature strength, and reduce toxic gases and the effect of toxic fumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

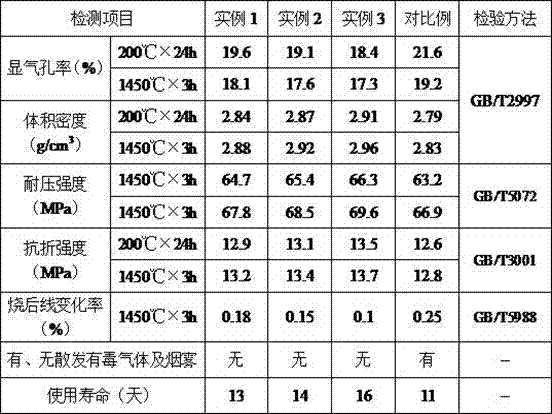

Examples

example 1

[0022] First, in parts by weight, add 10 parts of brown fused alumina with a mesh size of 6 mesh, 10 parts of brown fused alumina with a mesh size of 30 mesh, 10 parts of brown fused alumina with a mesh size of 70 mesh, and 10 parts of brown fused alumina with a mesh size of 100 mesh in the mixer. Target brown fused alumina, 20 parts of brown fused alumina with a mesh size of 180 mesh, stirred and mixed for 2 hours at a rotating speed of 300r / min, and discharged to obtain compound brown fused alumina. 10 parts of dense corundum with a mesh of 20 mesh, 10 parts of dense corundum with a mesh of 60 mesh, 10 parts of dense corundum with a mesh of 90 mesh, 10 parts of dense corundum with a mesh of 150 mesh, 20 parts of dense corundum with a mesh of 325 mesh, Stir and mix for 2 hours at a rotating speed of 300r / min, and discharge to obtain compound dense corundum. Then, in parts by weight, add 20 parts of sodium silicate, 40 parts of calcium silicate, and 8 parts of Aluminum dihydro...

example 2

[0024]First, according to the number of parts by weight, 15 parts of brown fused alumina with a mesh size of 13 mesh, 13 parts of brown corundum with a mesh size of 45 mesh, 20 parts of brown corundum with a mesh size of 80 mesh, and 13 parts of brown corundum with a mesh size of 125 mesh are sequentially added to the mixer. Target brown corundum, 30 parts of brown corundum with a mesh size of 240 mesh, under the condition of a rotating speed of 400r / min, stir and mix for 3 hours, and discharge the material to obtain compound brown corundum, and then add it to the mixer in order according to the number of parts by weight 15 copies of dense corundum with a mesh of 25 mesh, 13 copies of dense corundum with a mesh of 65 mesh, 20 copies of dense corundum with a mesh of 95 mesh, 13 copies of dense corundum with a mesh of 165 mesh, 30 copies of dense corundum with a mesh of 410 mesh, Stir and mix for 3 hours at a rotating speed of 400r / min, and discharge to obtain compound dense coru...

example 3

[0026] First, in parts by weight, add 20 parts of brown fused alumina with a mesh size of 20 mesh, 15 parts of brown fused alumina with a mesh size of 60 mesh, 30 parts of brown corundum with a mesh size of 90 mesh, and 15 parts of brown corundum with a mesh size of 90 mesh in the mixer. Target brown corundum, 40 parts of brown corundum with a mesh size of 300 mesh, stirred and mixed for 4 hours under the condition of a rotating speed of 500r / min, and discharged to obtain compound brown corundum. 20 parts of dense corundum with a mesh size of 30 mesh, 15 parts of dense corundum with a mesh size of 70 mesh, 30 parts of dense corundum with a mesh size of 100 mesh, 15 parts of dense corundum with a mesh size of 180 mesh, and 40 parts of dense corundum with a mesh size of 500 mesh. Stir and mix for 4 hours at a rotating speed of 500r / min, and discharge to obtain compound dense corundum. Then, in parts by weight, add 40 parts of sodium silicate, 60 parts of calcium silicate, and 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com