Organosilicone weather-resistant brushed decorative coating

A decorative coating and weather-resistant technology, applied in coatings and other directions, can solve the problems of large types and contents of additives, large VOC emissions, complex production processes, etc., and achieve the effects of excellent environmental protection, good adhesion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

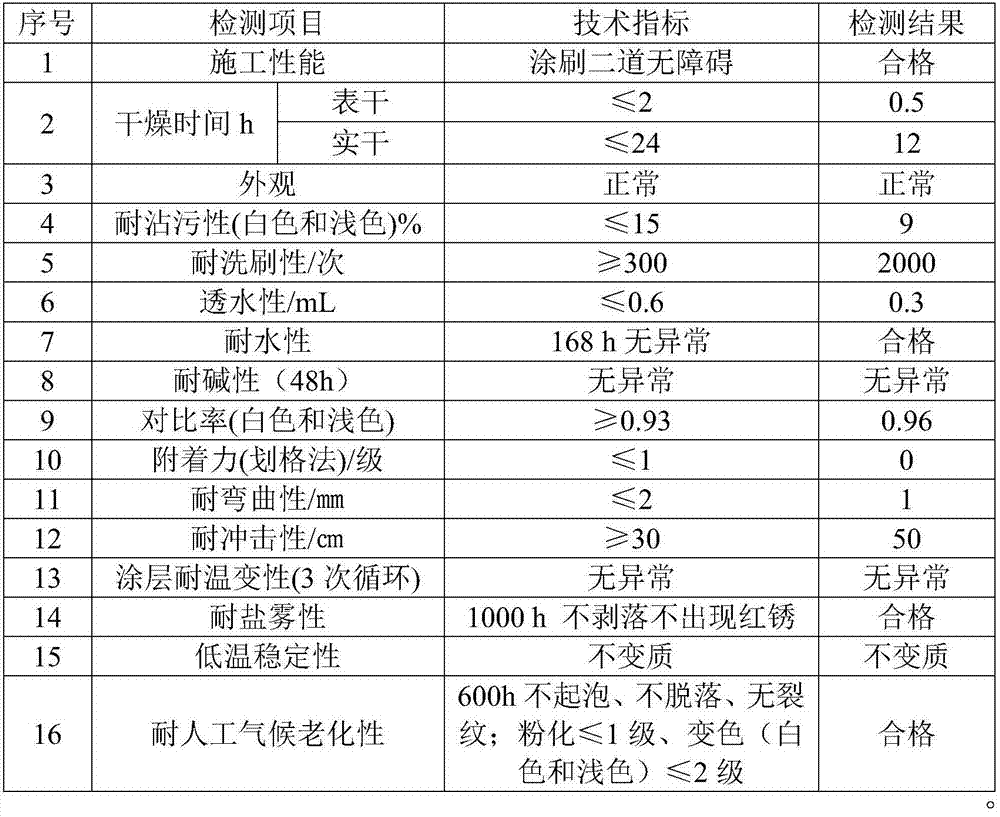

Image

Examples

Embodiment 1

[0039] A silicone weather-resistant brushed decorative coating, which is prepared by mixing the following raw material components in parts by weight: α, ω-dihydroxy polydimethylsiloxane I: 50 parts, α, ω-dihydroxy polydimethylsiloxane Methylsiloxane II: 50 parts, fumed silica: 15 parts, aluminum hydroxide: 60 parts, acicular wollastonite powder: 5 parts, glass fiber: 5 parts, rutile titanium dioxide: 25 parts, nanocarbonic acid Calcium: 15 parts, hydroxy silicone oil: 15 parts, pigment: 20 parts, cross-linking reagent (mixture of methyl tributylketoxime silane and phenyl tributylketoxime silane in a mass ratio of 4:6): 13 Parts, coupling agent (a mixture of γ-aminopropyltriethoxysilane and γ-glycidyloxypropyltrimethoxysilane at a mass ratio of 1:1): 0.85 parts, defoamer (Deqian 5300, Commercially available): 0.2 parts, wetting and dispersing agent (BYK065, commercially available): 0.5 parts, catalyst (dibutyltin dilaurate): 5 parts.

Embodiment 2

[0044] A silicone weather-resistant brushed decorative coating, which is prepared by mixing the following raw material components in parts by weight: α, ω-dihydroxy polydimethylsiloxane I: 20 parts, α, ω-dihydroxy polydimethylsiloxane Methylsiloxane II: 80 parts, fumed silica: 5 parts, aluminum hydroxide: 40 parts, acicular wollastonite powder: 20 parts, glass fiber: 15 parts, rutile titanium dioxide: 10 parts, nanocarbonic acid Calcium: 30 parts, hydroxyl silicone oil: 5 parts, pigment: 5 parts, crosslinking agent (tetrabutanoximinosilane): 5 parts, coupling agent (N-(β-aminoethyl)-γ-aminopropyl trimethoxysilane): 0.35 parts, defoamer (Deqian 5300, commercially available): 0.1 part, wetting and dispersing agent (BYK065, commercially available): 0.2 parts, catalyst (dibutyltin dilaurate and dilauric acid Dioctyltin (a mixture of 1:1 by mass ratio): 2.5 parts.

[0045] Described nano-calcium carbonate is polybutylacrylate grafted nano-calcium carbonate, and the preparation met...

Embodiment 3

[0049] A silicone weather-resistant brushed decorative coating, which is prepared by mixing the following raw material components in parts by weight: α, ω-dihydroxy polydimethylsiloxane I: 40 parts, α, ω-dihydroxy polydimethylsiloxane Methylsiloxane II: 70 parts, fumed silica: 10 parts, aluminum hydroxide: 50 parts, acicular wollastonite powder: 10 parts, glass fiber: 8 parts, rutile titanium dioxide: 15 parts, nanocarbonic acid Calcium: 20 parts, hydroxy silicone oil: 10 parts, pigment: 10 parts, cross-linking agent (methyl tributylketoximosilane): 8 parts, coupling agent (γ-methacryloxypropyl trimethoxy silane): 0.6 parts, defoamer (Deqian 5300, commercially available): 0.15 parts, wetting and dispersing agent (BYK065, commercially available): 0.3 parts, catalyst (dioctyltin dilaurate): 3.5 parts.

[0050] Described nano-calcium carbonate is polybutylacrylate grafted nano-calcium carbonate, and the preparation method of described polybutylacrylate-grafted nano-calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com