Solid fuel useful for coal substitutions

A technology for solid fuels and substitutes, applied in the field of solid fuels, can solve the problems of serious energy consumption, processing temperature exceeding 450 ℃, lengthy carbonization process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

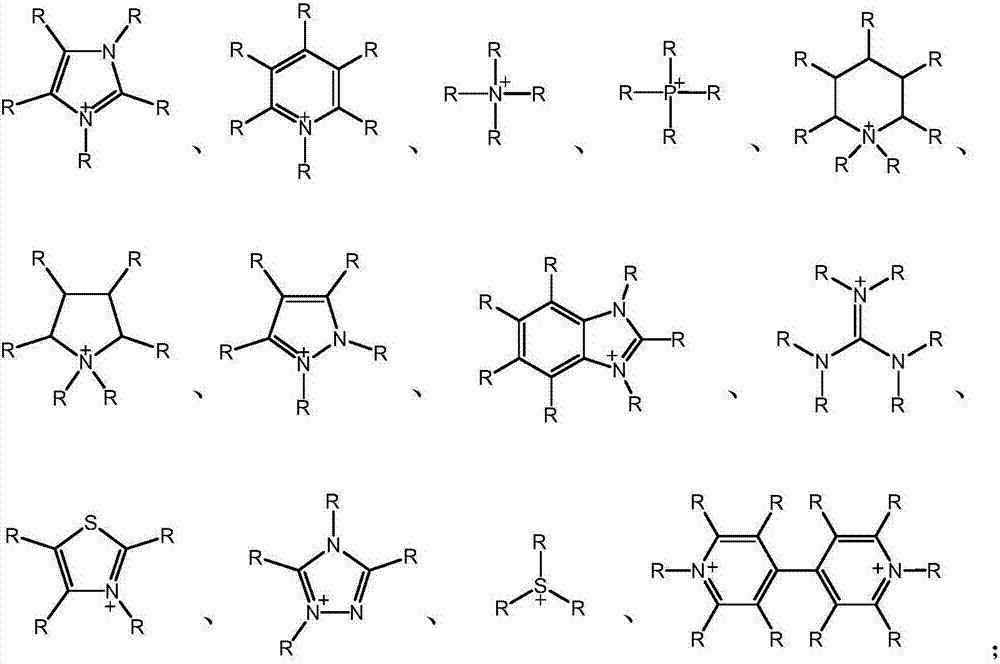

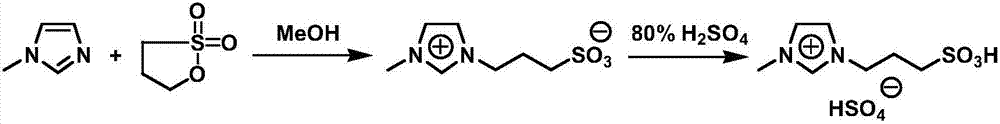

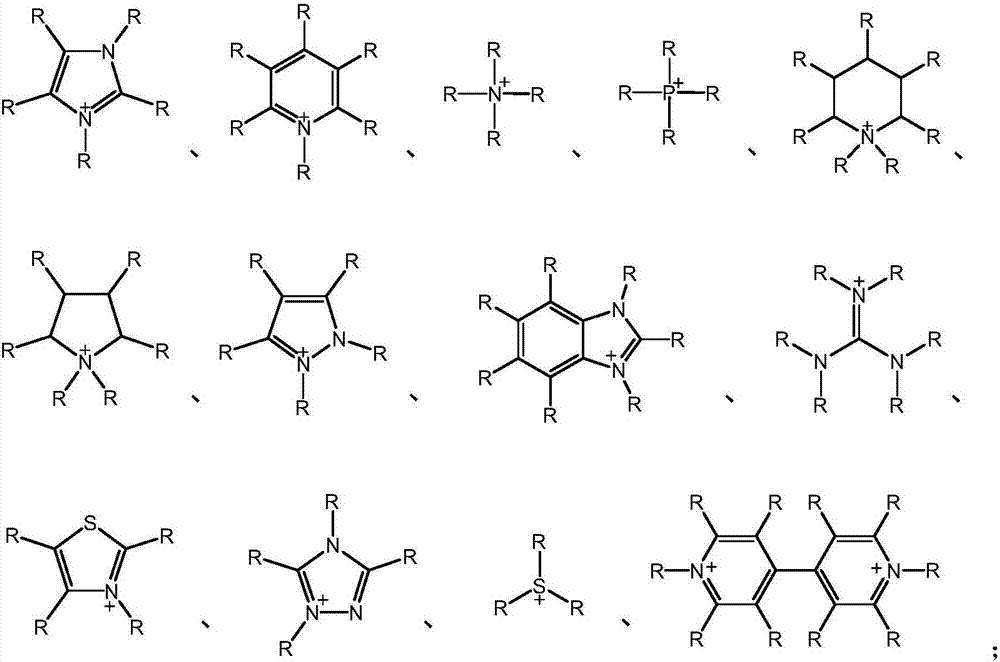

Method used

Image

Examples

Embodiment 1

[0024] Cellulose (2.200g), [C 3 SO 3 Hmim] HSO 4 After mixing ionic liquid (1.000g) and deionized water (6.000g), react at 170°C for 5 hours. The reaction solution is filtered to obtain solid black residue. After washing with water and drying, it is a solid fuel. The measured combustion calorific value is 21745J / g. Among them, the ionic liquid can be recycled.

Embodiment 2

[0026] Cellulose (2.200g), [C 3 SO 3 Hmim] HSO 4 After mixing ionic liquid (1.000g) and deionized water (6.000g), react at 170°C for 5 hours. The reaction liquid is filtered to obtain solid black residue, which is solid fuel after washing with acetone and drying. The calorific value of combustion is determined as 23394J / g. Among them, the ionic liquid can be recycled.

Embodiment 3

[0028] Cellulose (2.200g), 1-methyl-3-(4-sulfonate) butylimidazole benzenesulfonate ([C 4 SO 3 Hmim] PhSO 3 ) ionic liquid (1.000g) and deionized water (3.000g) were mixed, reacted at 180°C for 8 hours, the reaction solution was filtered to obtain solid black residue, washed with water and dried, it was solid fuel, and the heat of combustion was measured as 23440J / g. Among them, the ionic liquid can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com