Metal-ion battery and method for preparing the same

A metal ion and battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve problems such as low battery capacity and low battery discharge voltage, and achieve the effect of increasing the number of discharge voltage platforms and increasing the total power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

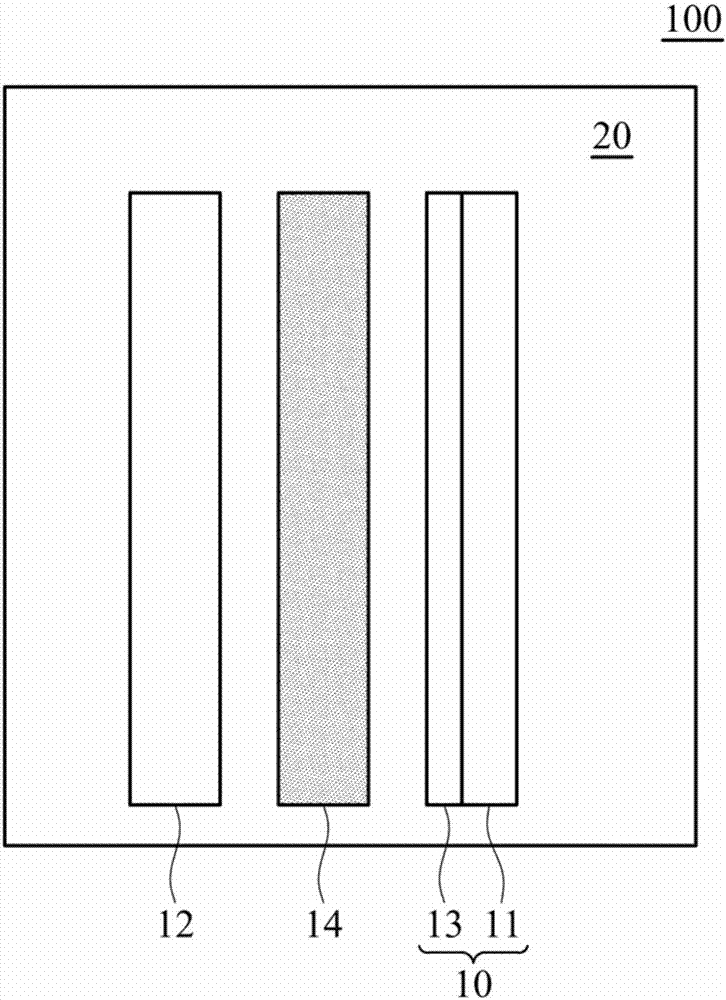

[0035] Provide an aluminum foil with a thickness of 0.025mm and cut it to obtain an aluminum electrode. Next, provide an isolation membrane (glass filter paper (2 layers), the product number is Whatman GFA) and a graphite electrode (including an active material arranged on a collector substrate, wherein the collector substrate is carbon fiber paper, The active material is expanded graphite (53mg)). Next, the aluminum electrode (as the negative electrode), the separator (as the separator), and the graphite electrode (as the positive electrode) are arranged in the order, and the aluminum plastic film is used to encapsulate and inject the electrolyte (aluminum chloride (AlCl) 3 ) / Ferrous chloride (FeCl 2 ) / 1-ethyl-3-methylimidazolium chloride ([EMIm]Cl), of which AlCl 3 FeCl 2 The total molar ratio of [EMIm]Cl is about 1.4:1, and FeCl 2 With AlCl 3 The molar ratio of is about 1:13) to obtain a metal ion battery (1).

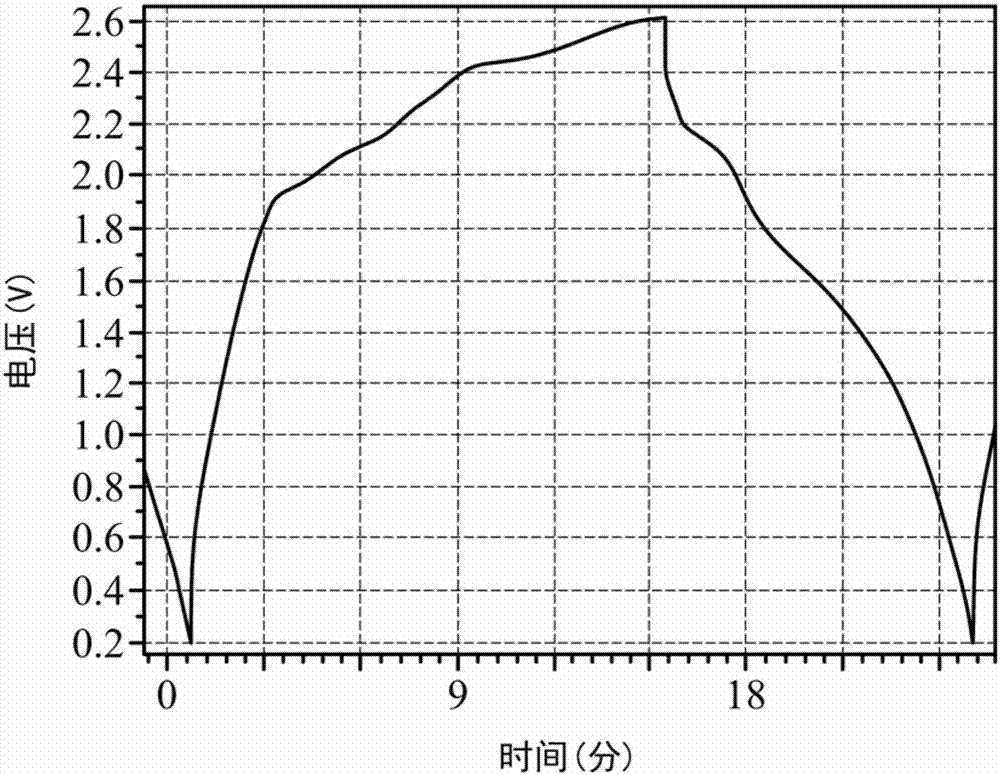

[0036] Next, use the NEWARE battery analyzer to measure the batte...

Embodiment 2

[0039] Provide an aluminum foil with a thickness of 0.025mm and cut it to obtain an aluminum electrode. Next, provide an isolation membrane (glass filter paper (2 layers), the product number is Whatman GFA) and a graphite electrode (including an active material arranged on a collector substrate, wherein the collector substrate is carbon fiber paper, The active material is expanded graphite (57mg)). Then, the aluminum electrode (as the negative electrode), the separator, and the graphite electrode (as the positive electrode) are arranged in the order, and the aluminum plastic film is used to encapsulate and inject the electrolyte (aluminum chloride (AlCl) 3 ) / Ferrous chloride (FeCl 2 ) / 1-ethyl-3-methylimidazolium chloride ([EMIm]Cl), of which AlCl 3 FeCl 2 The total molar ratio of [EMIm]Cl is about 1.4:1, and FeCl 2 With AlCl 3 The molar ratio is about 1:13) to obtain a metal ion battery (2).

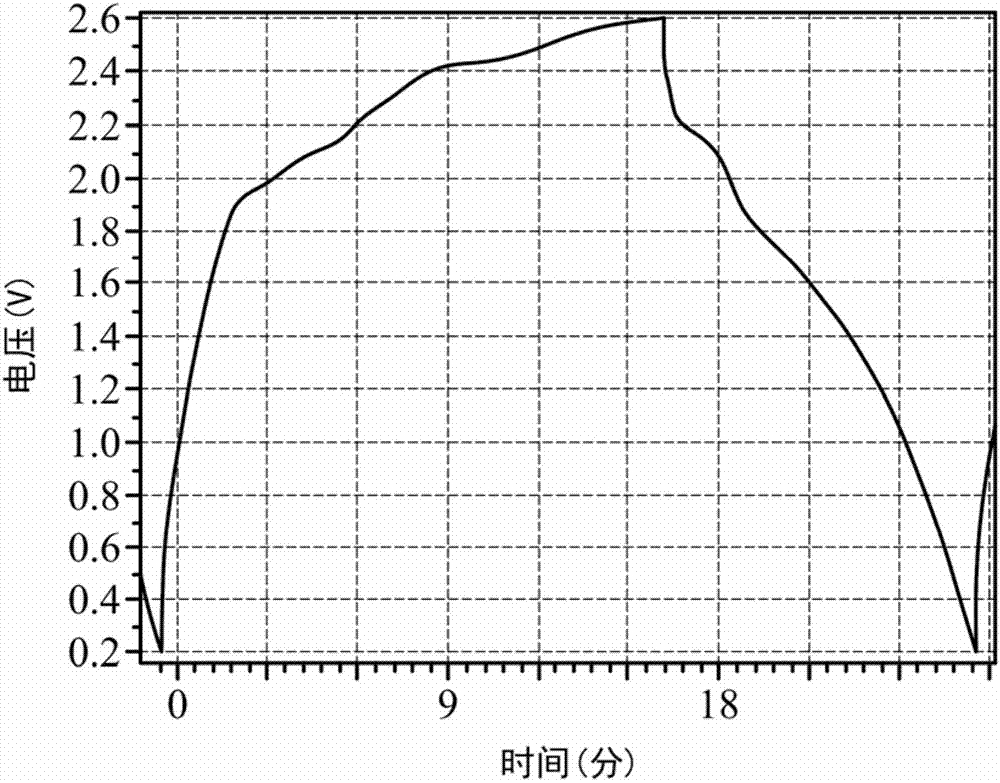

[0040] Next, use the NEWARE battery analyzer to measure the battery performance of the ...

Embodiment 3

[0042] Follow the method described in Example 1, except that FeCl 2 With AlCl 3 The molar ratio of Zn was changed from 1:13 to 1:27, and the expanded graphite was reduced from 53mg to 42mg to obtain a metal ion battery (3).

[0043] Next, use the NEWARE battery analyzer to measure the battery performance of the metal ion battery (3) obtained in Example 3 (the measurement conditions are: charge and discharge test (1000mA / g) in a constant current mode, and the charge cut-off voltage is 2.7V, The discharge cut-off voltage is 0.3V), it can be known that its maximum specific capacity is 176mAh / g, such as Figure 4 And as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com