Super-toughened glycidol ester modified amine hardener and preparation method thereof

A technology of glycidyl ester and curing agent, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. Effects of toughness and impact strength, low chlorine content, high epoxy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

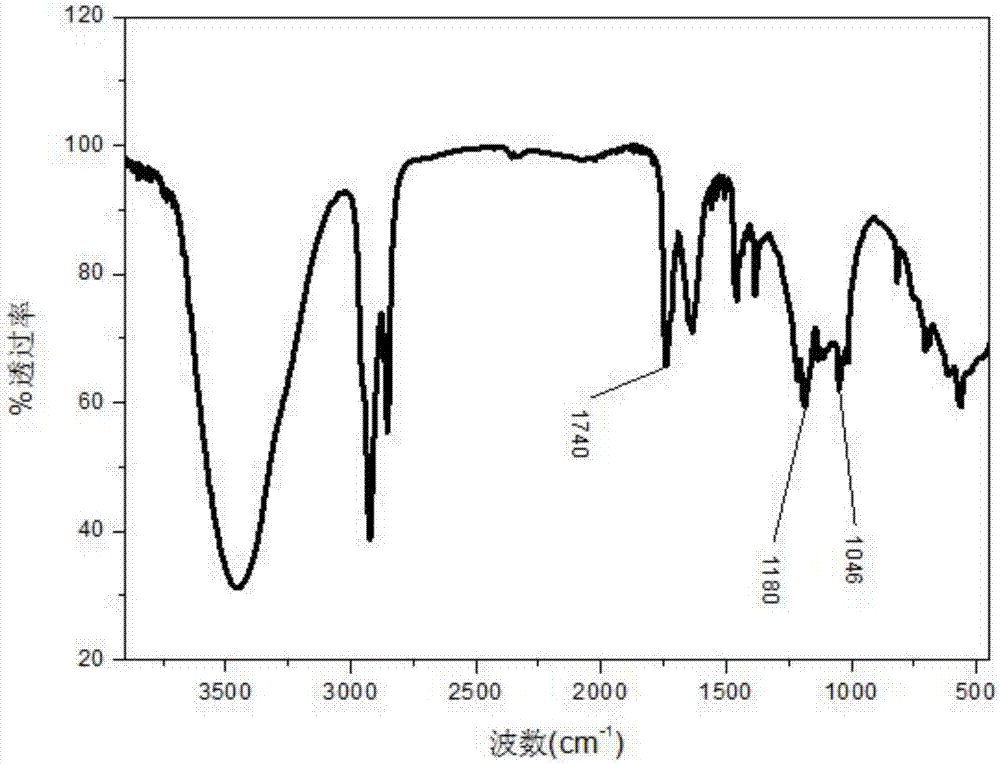

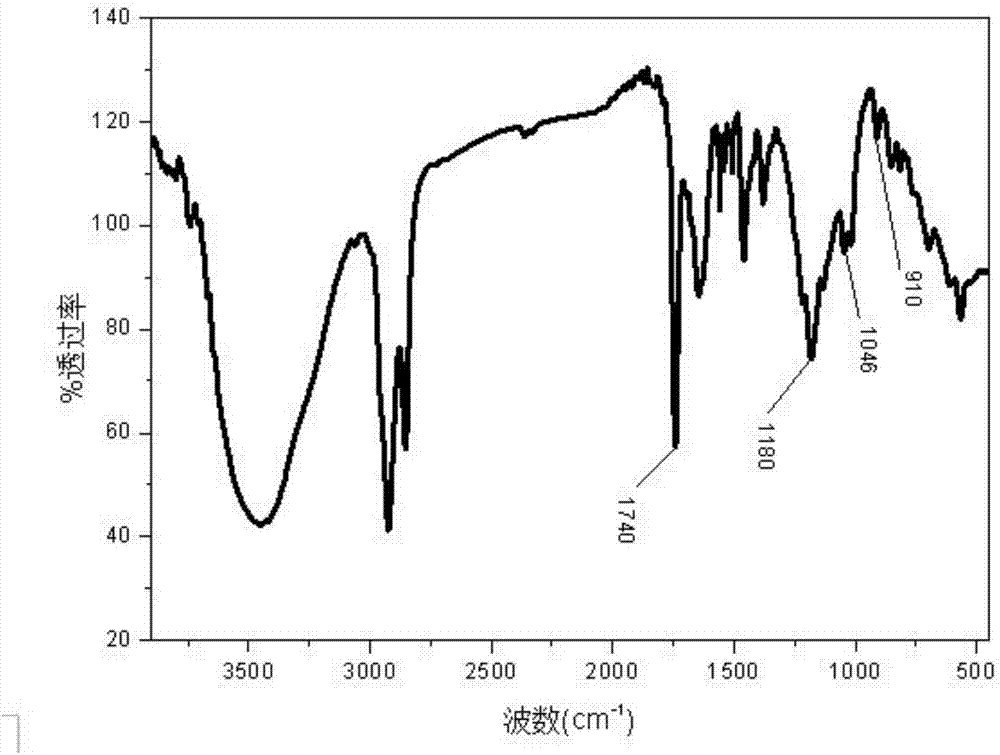

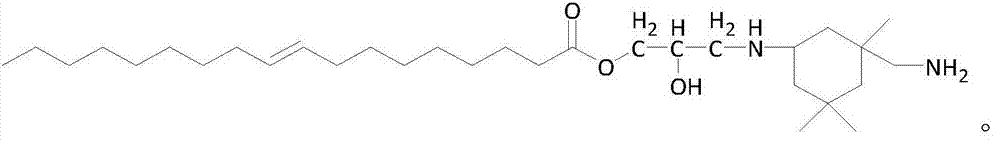

Method used

Image

Examples

Embodiment 1

[0040] (1) Heat 112.80g (0.40mol) oleic acid and 110.02g (1.19mol) epichlorohydrin to 50°C in a reactor with stirring, nitrogen protection, and condenser, and add 2.26g of catalyst tetrabutyl chloride Phosphine was reacted at 100°C for 2 hours to obtain the chlorohydrin ester intermediate, and the acid value of the chlorohydrin ester intermediate was measured to be 0.47 mgNaOH / g;

[0041] (2) Cool down to 85°C, add dropwise 112.00g of NaOH solution with a weight concentration of 20% (calculated as NaOH, 0.56mol), drop it for 2.1h, and then react at 85°C for 2h;

[0042] (3) After the cyclization is completed, add 225.60 g of toluene to extract 3 times, each time the amount is 1 / 3 of the total mass of toluene, combine the extracts of each batch, and then wash and neutralize the extracts at room temperature, Wash until the aqueous phase pH=7. Oil and water are separated, and the oil phase is gradually heated from room temperature to 140°C to remove under reduced pressure when t...

Embodiment 2

[0048] (1) Heat 112.80g (0.40mol) of oleic acid and 185.04g (2.00mol) of epichlorohydrin in a reactor with stirring, nitrogen protection, and condenser to 50°C and stir evenly, then add 4.51g of triethylamine After stirring for 10 minutes, the temperature was raised to 80° C., and the temperature was kept at 80° C. for 3 hours to obtain the chlorohydrin ester intermediate. The acid value of the chlorohydrin ester intermediate was measured to be 0.53 mgNaOH / g.

[0049](2) The temperature was lowered to 55° C., and 106.67 g (calculated as NaOH, 0.80 mol) of NaOH solution with a weight concentration of 30% was added dropwise to make it drop within 2.0 hours. After the dropwise addition, the constant temperature reaction was continued at 55° C. for 4 h.

[0050] (3) After the cyclization is completed, add 225.60 g of toluene to extract 3 times, each time the amount is 1 / 3 of the total mass of toluene, combine the extracts of each batch, and then wash and neutralize the extracts at...

Embodiment 3

[0054] (1) Heat 112.80g (0.40mol) of oleic acid and 259.06g (2.80mol) of epichlorohydrin in a reactor with stirring, nitrogen protection, and condenser to 50°C and stir evenly, then add 1.13g of tetrabutyl Phosphine bromide, after stirring for 10 minutes, the temperature was raised to 110 °C, and the temperature was kept at 110 °C for 1.5 hours to obtain the chlorohydrin ester intermediate, and the acid value of the chlorohydrin ester intermediate was measured to be 0.37 mgNaOH / g;

[0055] (2) Cool down to 70°C, add 44.00 g of 40% NaOH solution (calculated as NaOH, 0.44 mol) dropwise, and drop it within 0.8 h. After the dropwise addition, the constant temperature reaction was continued at 70° C. for 3 h;

[0056] (3) After the cyclization is completed, add 225.60 g of toluene to extract 3 times, each time the amount is 1 / 3 of the total mass of toluene, combine the extracts of each batch, and then wash and neutralize the extracts at room temperature, Wash until the aqueous pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com