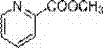

Synthesis method of methyl picolinate

A technology of methyl picolinate and a synthesis method, which is applied in the field of electrochemical organic synthesis, and achieves the effects of cheap and easily available raw materials, reduced air pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 A kind of synthetic method of methyl 2-pyridinecarboxylate, concrete steps are as follows:

[0019] a. Preparation of electrolyte

[0020] Mix 1 mmol (95 ul) 2-bromopyridine with 1 mmol (0.2102 g) tetraethylammonium bromide and 0.129 mol (10 mL) N, N -Dimethylformamide is mixed into an electrolyte, and then placed in a one-chamber electrolytic cell with silver as the cathode and magnesium rod as the anode, 2-bromopyridine, tetraethylammonium bromide and N,N -Dimethylformamide is analytically pure, wherein: 2-bromopyridine is a substrate, N,N -Dimethylformamide is the solvent after 4Å grade molecular sieve drying, and tetraethylammonium bromide is the supporting electrolyte;

[0021] b. Electrocarboxylation reaction

[0022] Under normal pressure, carbon dioxide was introduced into the above electrolytic cell for 30 min, and then at 8 mA / cm 2 Electrolyze at a constant current density of 2.0 F per mole of 2-bromopyridine, and F is the Faraday constant; ...

Embodiment 2

[0029] Embodiment 2 A kind of synthetic method of methyl 2-pyridinecarboxylate, concrete steps are as follows:

[0030] a. Preparation of electrolyte

[0031] Mix 1 mmol (95 ul) 2-bromopyridine with 1 mmol (0.3224 g) tetrabutylammonium bromide and 0.129 mol (10 mL) N,N -Dimethylformamide is mixed into an electrolyte, and then placed in a one-chamber electrolytic cell with a silver sheet as a cathode and a magnesium rod as an anode, 2-bromopyridine, tetrabutylammonium bromide and N,N -Dimethylformamide is analytically pure, wherein: 2-bromopyridine is a substrate, N,N -Dimethylformamide is the solvent after 4Å grade molecular sieve drying, and tetrabutylammonium bromide is the supporting electrolyte;

[0032] b. Electrocarboxylation reaction

[0033] Under normal pressure, carbon dioxide was introduced into the above electrolytic cell for 30 min, and then at 8 mA / cm 2 Electrolyze at a constant current density of 2.0 F per mole of 2-bromopyridine, and F is the Faraday consta...

Embodiment 3

[0040] Embodiment 3 A kind of synthetic method of methyl 2-pyridinecarboxylate, concrete steps are as follows:

[0041] Mix 1 mmol (95 ul) 2-bromopyridine with 1 mmol (0.3224 g) tetrabutylammonium bromide and 0.129 mol (10 mL) N,N -Dimethylformamide is mixed into an electrolyte, and then placed in a one-chamber electrolytic cell with nickel as the cathode and magnesium rod as the anode, 2-bromopyridine, tetrabutylammonium bromide and N,N -Dimethylformamide is analytically pure, wherein: 2-bromopyridine is a substrate, N,N -Dimethylformamide is the solvent after 4Å grade molecular sieve drying, and tetrabutylammonium bromide is the supporting electrolyte;

[0042] b. Electrocarboxylation reaction

[0043] Under normal pressure, carbon dioxide was introduced into the above electrolytic cell for 30 min, and then at 8 mA / cm 2 Electrolyze at a constant current density of 2.0 F per mole of 2-bromopyridine, and F is the Faraday constant;

[0044] c. Esterification reaction

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com