Method for utilizing camellia oleifera abel fruit shells to prepare cellulose nano-crystal whiskers

A technology of camellia husk and nano-whisker is applied in the post-processing of cellulose pulp, fiber raw material, fiber raw material processing and other directions, which can solve the problems such as not yet, and achieve strong Young's modulus, high reactivity, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

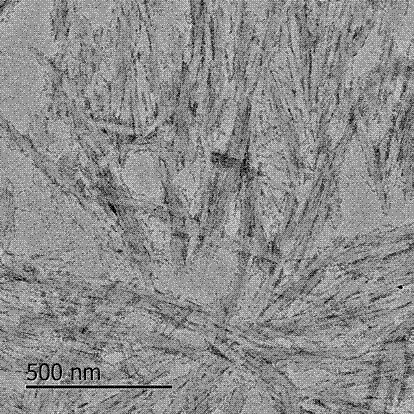

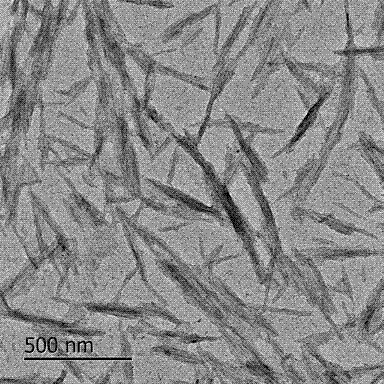

Image

Examples

Embodiment 1

[0040] S1. Mechanical treatment: take 100g of Camellia oleifera husk, wash it with distilled water, dry it in the sun, and cut it into 1cm pieces;

[0041] S2. Alkali treatment: get the 10g camellia oleifera husk in step S1, add to 50mL of 1(wt)%NaOH and 1(wt)%Na 2 SO 3 In the mixed solution, heat and stir in a water bath at 50°C for 180 minutes to remove lignin and obtain cellulose from camellia oleifera husk;

[0042] S3. Purification: Add 10 g of Camellia oleifera husk cellulose obtained in step S2 into 40 mL of 10 (wt)% NaOH solution, heat and stir in a water bath at 50° C. for 120 minutes, remove hemicellulose, and prepare Camellia oleifera husk fiber white;

[0043] S4. Bleaching: disperse 10 g of camellia husk cellulose obtained in step S3 into 100 mL of distilled water, add 2 mL of 30 wt % H 2 o 2 The solution was heated and stirred in a water bath at 40°C for 120 minutes, then filtered with a G4 sand core funnel, collected, placed in an oven, and dried at 50°C;

[...

Embodiment 2

[0048] S1. Mechanical treatment: take 100g of Camellia oleifera husk, wash it with distilled water, dry it in the sun, and cut it into 1cm pieces;

[0049] S2. Alkali treatment: get 10g Camellia oleifera husk in step S1, add 3(wt)%NaOH and 3(wt)%NaOH to 60mL 2 SO 3 In the mixed solution, heat and stir in a water bath at 60°C for 120 minutes to remove lignin and obtain cellulose from camellia oleifera husk;

[0050] S3. Purification: the Camellia oleifera husk cellulose that 10g step S2 gained is joined in the 14(wt)% NaOH solution of 60mL, 60 ℃ Heating and stirring in a water bath for 90 minutes to remove the hemicellulose and prepare the camellia oleifera husk cellulose;

[0051] S4. Bleaching: disperse 10 g of camellia oleifera cellulose obtained in step S3 into 100 mL of distilled water, add 3 mL of 30 wt % H 2 o 2 The solution was heated and stirred in a water bath at 45°C for 100 minutes, then filtered with a G4 sand core funnel, collected, placed in an oven, and drie...

Embodiment 3

[0056] S1. Mechanical treatment: take 100g of Camellia oleifera husk, wash it with distilled water, dry it in the sun, and cut it into 1cm pieces;

[0057] S2. lye treatment: get 10g camellia oleifera husk in step S1, add 4(wt)%NaOH and 4(wt)%NaOH to 70mL 2 SO 3 In the mixed solution, heat and stir in a water bath at 70°C for 90 minutes to remove lignin and obtain cellulose from camellia oleifera husk;

[0058] S3. Purification: Add 10 g of Camellia oleifera husk cellulose obtained in step S2 into 70 mL of 18 (wt)% NaOH solution, heat and stir in a water bath at 70°C for 80 minutes, remove hemicellulose, and prepare Camellia oleifera husk fiber white;

[0059] S4. Bleaching: disperse 10 g of the camellia husk cellulose obtained in step S3 into 100 mL of distilled water, add 4 mL of 30 wt % H 2 o 2 The solution was heated and stirred in a water bath at 50°C for 80 minutes, then filtered with a G4 sand core funnel, collected, placed in an oven, and dried at 50°C;

[0060] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com