Preparation method of spiral implantable minimally-invasive glucose sensor with PVA (polyvinyl alcohol)/PEG (polyethylene glycol) composite hydrogel outer membrane structure

A glucose sensor and composite hydrogel technology, applied in the field of biosensors, can solve the problems of short service life, loss of sensitivity, sensor failure, etc., and achieve good repeatability and long-term stability, good film formation and tensile strength. , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

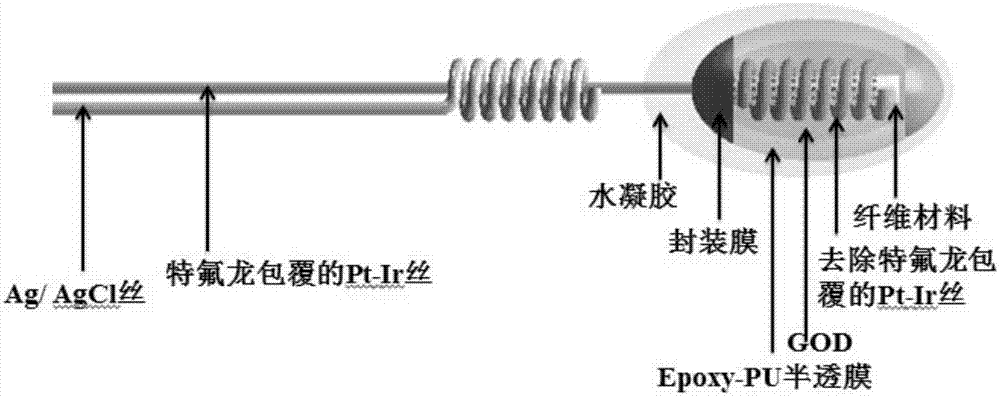

[0037] Embodiment 1: The preparation method of the helical implantable minimally invasive glucose sensor based on PVA / PEG composite hydrogel outer membrane structure, including the following steps

[0038] (1) Take a medical-grade platinum-iridium wire about 5 cm long, peel off the Teflon coating at the end of 0.5 cm, and ultrasonically treat it in ultrapure water for 5 minutes; The injection needle (30gauge) is tightly coiled and wound 8 times to obtain a Pt-Ir coil;

[0039] (2) Embedding a small strand of porous fiber material in the helical coil prepared above;

[0040] (3) Dissolve 0.012 g of bovine serum albumin and 0.0025 g of glucose oxidase in 300 μL of deionized water, stir evenly on a shaker, drop in 4.8 μL of glutaraldehyde, and continue stirring;

[0041] (4) Take 8 μL of the stirred GOD solution and drop-coat it on the surface of the electrode. After natural drying at room temperature, take 8 μL of the stirred GOD solution and drop-coat it on the surface of the ...

Embodiment 2

[0050] Embodiment 2, the preparation of PVA / PEG composite hydrogel:

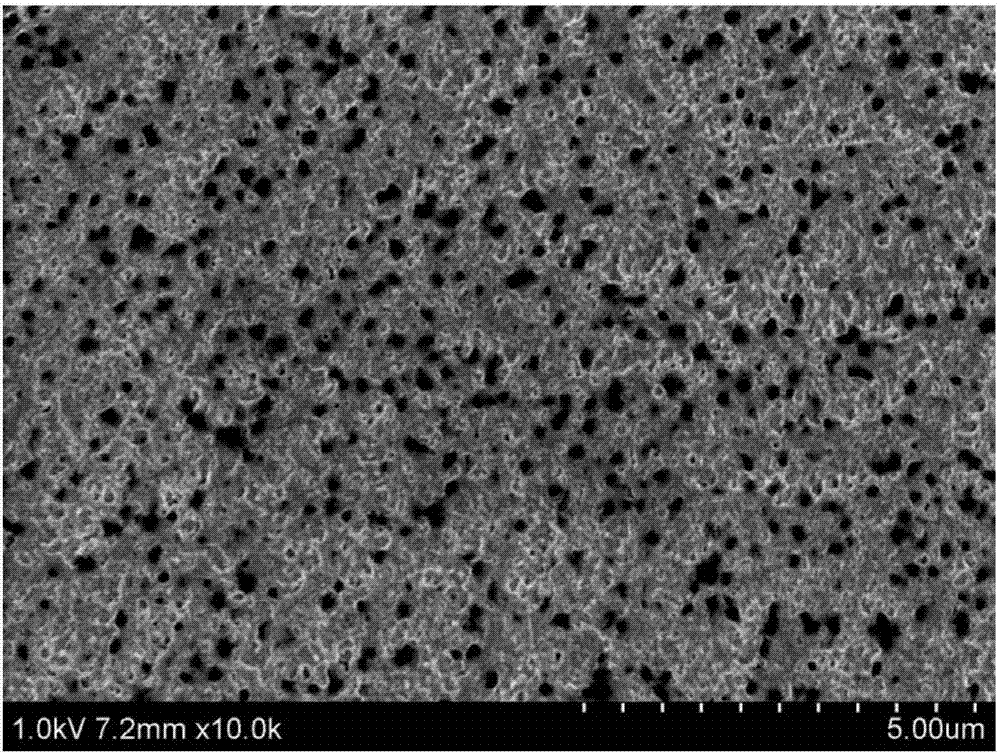

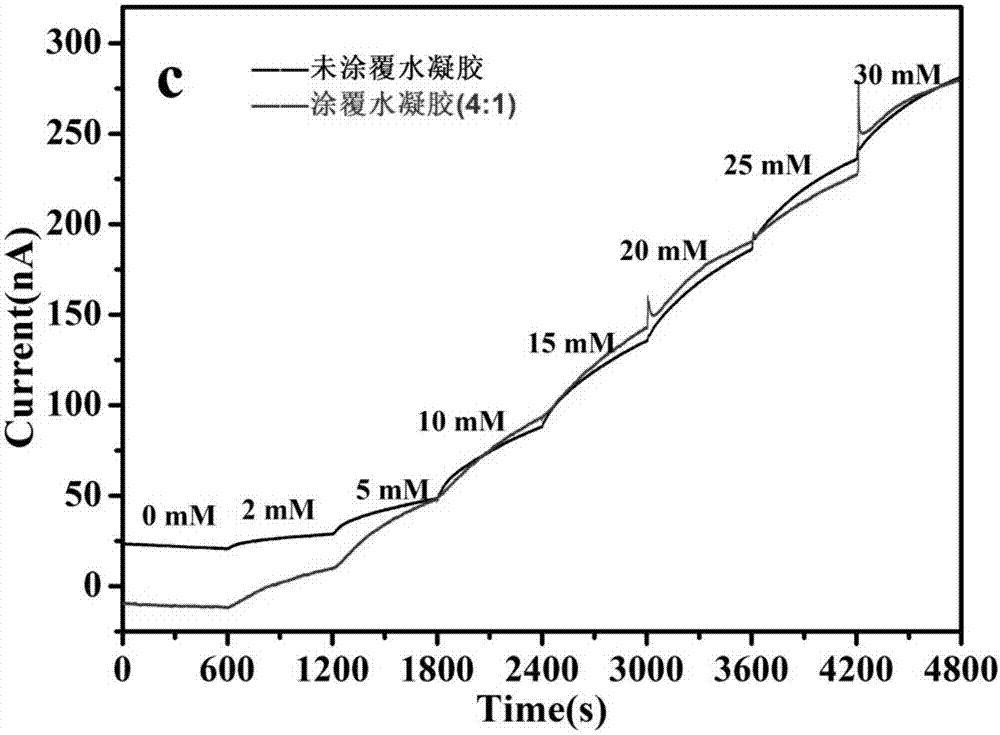

[0051] In the step (9) of embodiment 1, mass ratio is polyvinyl alcohol: polyethylene glycol=4:1, can change polyvinyl alcohol: polyethylene glycol=2:1, other steps and conditions are all with implementation Example 1 is the same, and specific conditions are changed and adjusted accordingly within the scope of the content of the invention, composite hydrogels can be obtained, and the preparation scanning electron microscope (SEM) photos of composite hydrogels are shown in figure 2 ; The comparison chart of the sensor without hydrogel and the sensor coated with polyvinyl alcohol / polyethylene glycol hydrogel for different glucose concentrations, see image 3 ,4.

Embodiment 3

[0052] Embodiment 3, the preparation of PVA / PEG composite hydrogel;

[0053] In the step (9) of embodiment 1, mass ratio is polyvinyl alcohol: polyethylene glycol=4:1, can change polyvinyl alcohol: polyethylene glycol=5:1, other steps and conditions are all with implementation The same as Example 1, the specific conditions are changed and adjusted accordingly within the scope of the content of the invention, and the composite hydrogel can be obtained. Comparison of the sensor without hydrogel and the sensor coated with polyvinyl alcohol / polyethylene glycol hydrogel for different glucose concentrations, see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com