High-conductivity heat-conduction oil

A heat-conducting oil and high-conductivity technology, applied in the chemical industry, can solve the problems of shortening the service life of heat-conducting oil, increasing viscosity and carbon residue, increasing the viscosity of heat-conducting oil, etc., and achieving the effects of prolonging service life, not easy to coke, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

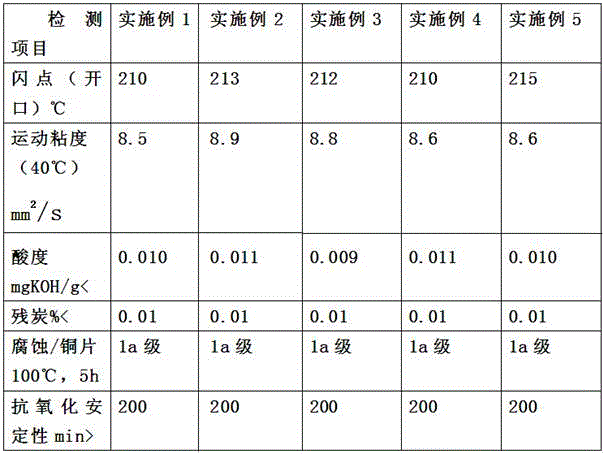

Examples

Embodiment 1

[0024] 1) Weigh 80 parts of base oil, 5 parts of detergent and dispersant, 5 parts of high temperature antioxidant, 5 parts of antioxidant and anticorrosion agent, 2 parts of oily agent, 1 part of coking inhibitor, 1 part of pour point depressant, viscosity 1 part index improver, 1 part metal deactivator, 1 part rust inhibitor, 1 part nanoparticle.

[0025] Among them, the detergent and dispersant is a mixture of overbasic alkylphenate, calcium sulfurized alkylphenate with high alkalinity, and succinimide. The high-temperature antioxidant is 2,6-di-tert-butyl-α-dimethylamino-p-cresol. Antioxidant and anticorrosion agent is sulfur phosphorus dialkyl zinc salt. The oily agent is butyl stearate. The pour point depressant is polyoxyethylene sorbitan monolauryl ester, a mixture of α-olefin and maleic anhydride copolymer. Viscosity index improvers include polyvinyl n-butyl ether, oxidized polyethylene wax, polyoxypropyl polyoxyethyl glyceryl ether, acrylamide, and sulfurized sper...

Embodiment 2

[0029] 1) Weigh 100 parts of base oil, 5.8 parts of detergent and dispersant, 7 parts of high-temperature antioxidant, 6 parts of anti-oxidant and anti-corrosion agent, 3 parts of oiliness agent, 1.5 parts of coking inhibitor, 1.5 parts of pour point depressant, viscosity 1.5 parts of index improver, 1.3 parts of metal deactivator, 1.5 parts of rust inhibitor, and 1.5 parts of nanoparticles.

[0030] Among them, the detergent and dispersant is a mixture of high alkali value sulfurized alkyl phenate calcium, succinimide, and borated high molecular weight polyisobutenyl succinimide. The high temperature antioxidant is thionyl octyl zinc salt. The antioxidant and anticorrosion agent is a mixture of phosphodialkyl zinc salt and thiophosphobioctyl basic zinc salt. The oily agent is butyl stearate. The pour point depressant is a mixture of polyoxyethylene sorbitan monolauryl ester and polymethacrylate. The viscosity index improver is a mixture of polyvinyl n-butyl ether, oxidized...

Embodiment 3

[0034] 1) Weigh 105 parts of base oil, 6.5 parts of detergent and dispersant, 7.8 parts of high temperature antioxidant, 6.8 parts of antioxidant and anticorrosion agent, 4 parts of oiliness agent, 2 parts of coking inhibitor, 2 parts of pour point depressant, viscosity 2 parts of index improver, 1.5 parts of metal deactivator, 1.6 parts of rust inhibitor, 2 parts of nanoparticles.

[0035] Among them, the detergent and dispersant is a mixture of overbased alkyl phenate, high base value sulfurized alkyl phenate calcium, succinimide, and borated high molecular weight polyisobutenyl succinimide. The high temperature antioxidant is alkyl diphenylamine. The anti-oxidant and anti-corrosion agent is basic zinc salt of bis-octyl thiophosphor. The oily agent is butyl stearate. The pour point depressant is a mixture of α-olefin, maleic anhydride copolymer and polymethacrylate. The viscosity index improver is a mixture of polyvinyl n-butyl ether, oxidized polyethylene wax, polyoxypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com