MOFs compound film, preparation method and application thereof

A composite membrane and support membrane technology, applied in the field of composite membranes, can solve the problems of inability to precisely control the density of ion channels, achieve excellent scalability, reduce crystallization, and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

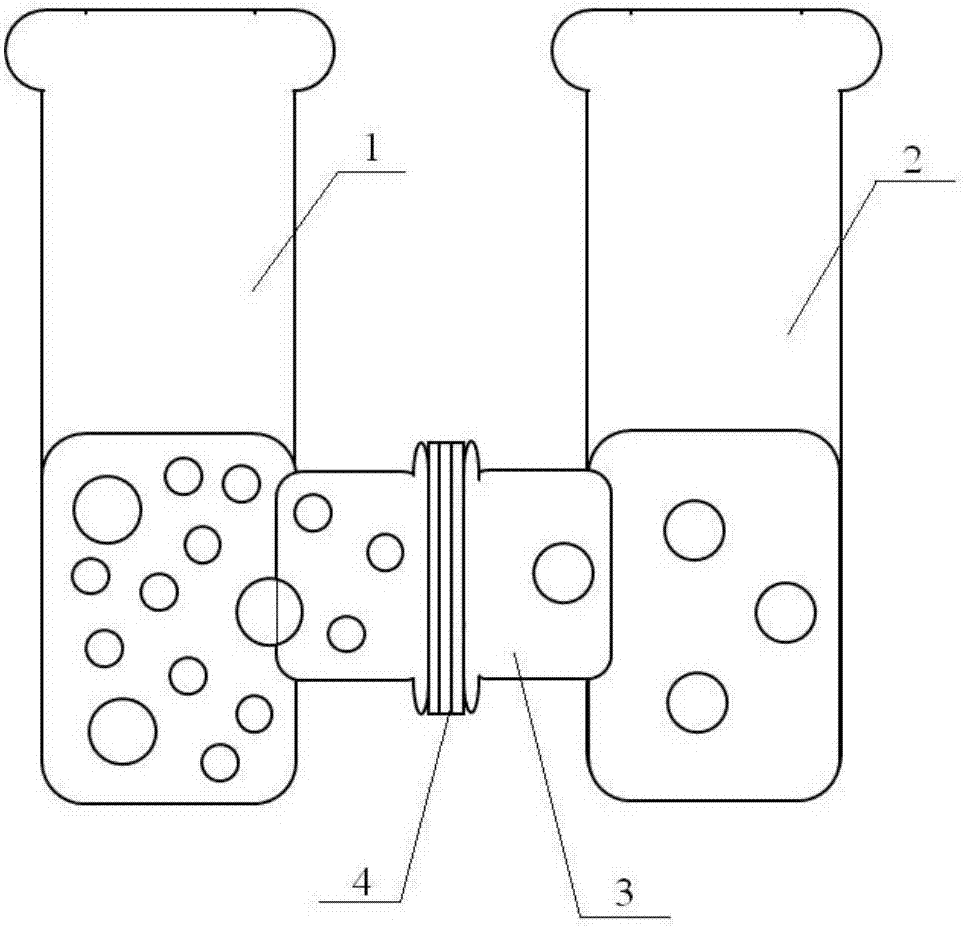

[0032] 1.1 Put a commercial porous alumina base membrane with a pore size of 80-100 nm on figure 1Fix it in the reaction device shown, check whether it leaks, and add a gasket if it leaks.

[0033] 1.2 Add 40mL of 2.7mmol zirconium tetrachloride, 36mL of 3.75mmol of 2-aminoterephthalic acid and 4mL of concentrated hydrochloric acid to the left chamber 1 and right chamber 2, respectively, and place the device in an oven at 80 ℃, reacted for 48h, closed the oven, and let it cool down naturally. Remove the membrane in the device, which is the pure-phase MOFs composite membrane, and soak it in N,N-dimethylformamide.

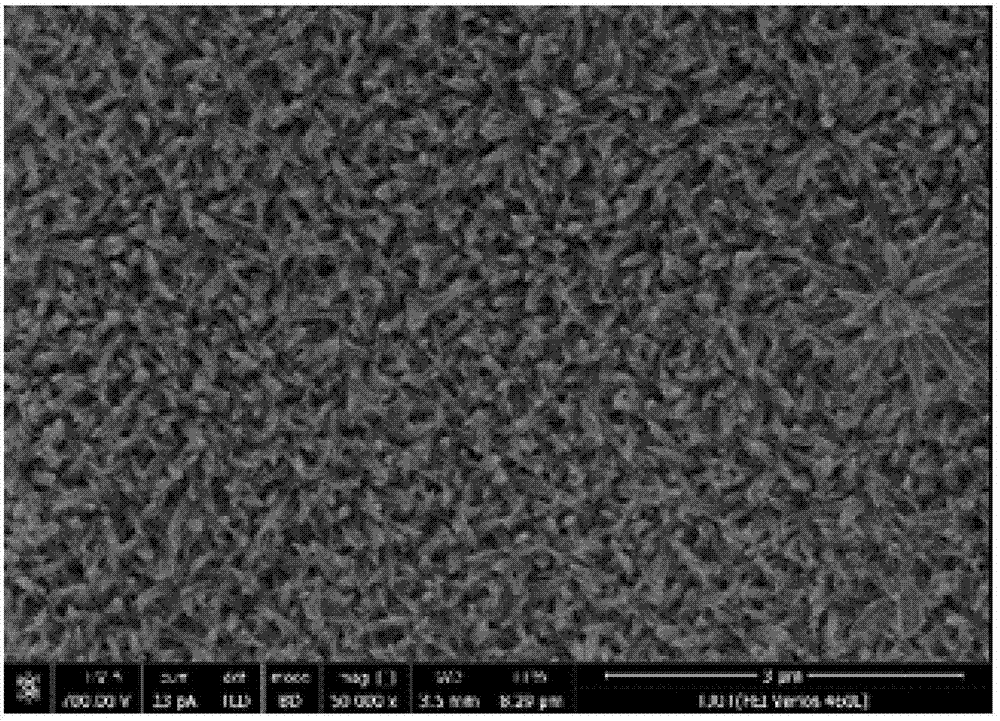

[0034] Utilize scanning electron microscope to analyze the phase-pure MOFs composite membrane that obtains in embodiment 1, obtain its scanning electron microscope picture, as figure 2 as shown, figure 2 Scanning electron micrographs of MOFs composite membranes prepared for the examples of the present invention.

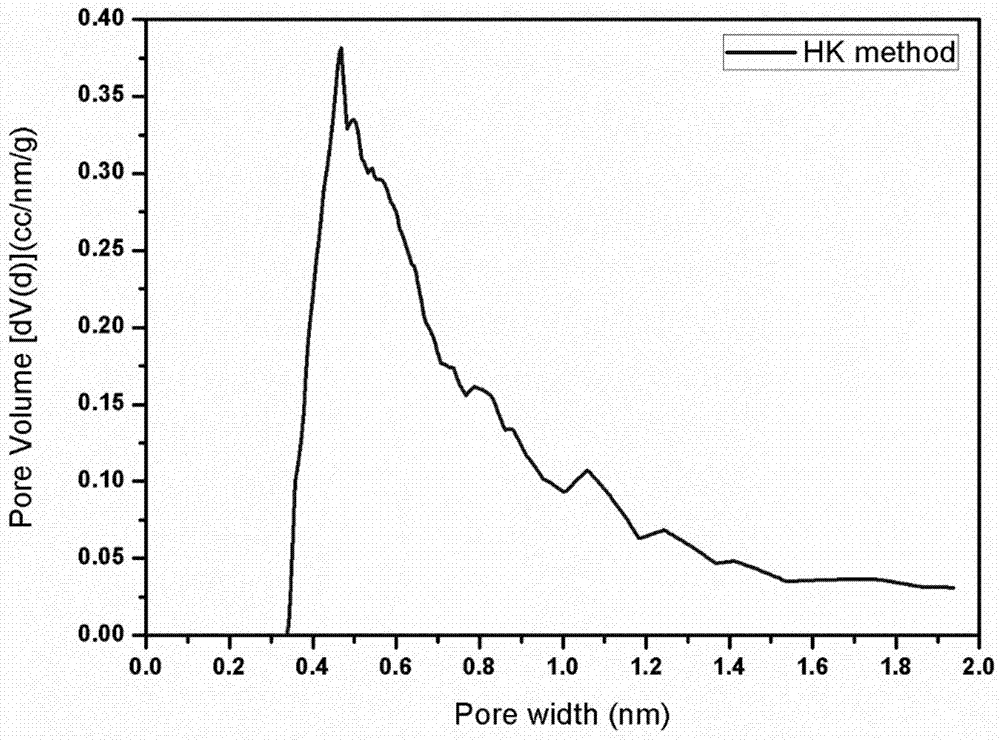

[0035] For UiO-66-NH synthesized by the same me...

Embodiment 2

[0038] 2.1 Fix the commercial porous alumina base membrane with a pore size of 40-70nm in the device, check whether it leaks, and add a gasket if it leaks.

[0039] 2.2 Add 40mL of 0.54mmol zirconium tetrachloride, 36mL of 0.75mmol of 2-aminoterephthalic acid and 4mL of concentrated hydrochloric acid to the left chamber 1 and right chamber 2 respectively, place the device in an oven, and heat it at 100 ℃, reacted for 48h, closed the oven, and let it cool down naturally. Remove the membrane in the device, that is, the pure-phase MOFs composite membrane, and soak it in N,N-dimethylformamide.

[0040] exist Figure 5 In the electrodialysis device shown, the performance of the pure-phase MOFs separation membrane for separating divalent ions was tested, and the test was carried out in a constant current mode with a current of 0.01A. The results show that the pure-phase MOFs composite membrane obtained in Example 1 has a selectivity of 95.84 for the separation of sodium and magnes...

Embodiment 3

[0042] 3.1 Fix the commercial polytetrafluoroethylene-based membrane with a pore size of 100nm in the device, check whether it leaks, and add a gasket if it leaks.

[0043] 3.2 Add 40mL of 2.7mmol zirconium tetrachloride, 36mL of 3.75mmol of 2-aminoterephthalic acid and 4mL of concentrated hydrochloric acid to the left chamber 1 and right chamber 2, respectively, and place the device in an oven at 80 ℃, reacted for 24h, closed the oven, and let it cool down naturally. Remove the membrane in the device, that is, the pure-phase MOFs composite membrane, and soak it in N,N-dimethylformamide.

[0044] exist Figure 5 In the electrodialysis device shown, the performance of the pure-phase MOFs separation membrane for separating divalent ions was tested, and the test was carried out in a constant current mode with a current of 0.01A. The results show that the pure-phase MOFs composite membrane obtained in Example 1 has a selectivity of 90.96 for sodium and magnesium ions, and a sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com