Method for preparing functionalized graphene through ball milling

A graphene and ball milling technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex synthesis process, weak interaction, difficult processing, etc., and achieve simple operation method, good dispersibility, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing functionalized graphene by ball milling, comprising the steps of:

[0040] Add 0.3 grams of flake graphite and 3 grams of p-bromoaniline into a 100ml ball mill jar. The grinding balls are two kinds of mixed stainless steel balls with a diameter of 5mm and 10mm. After mixing well, add 3.6 grams of isoamyl nitrite, and then fix On the ball mill, the rotating speed is 400 rpm, and the ball milling time is 8 hours. The obtained product was washed and separated, and then dried at 60° C. to obtain a graphene powder whose surface was functionalized with bromobenzene.

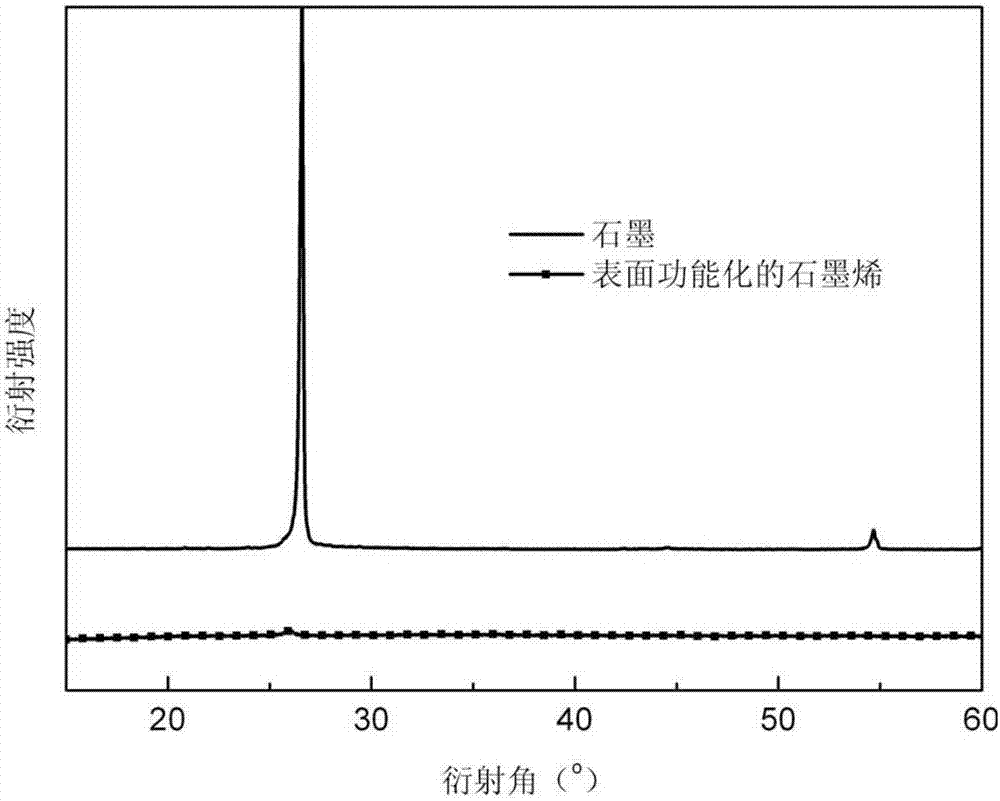

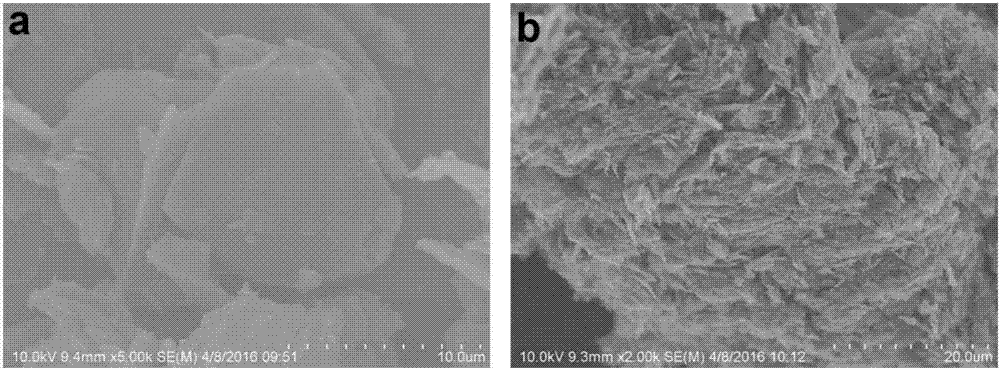

[0041]Such as figure 1 Shown is the X-ray diffraction (XRD) diffraction pattern of flake graphite and bromobenzene functionalized graphene in the present embodiment. It can be seen from the X-ray electron diffraction data that pure graphite has a strong [002] diffraction peak at 26.5°, showing that the graphitic carbon-carbon layer spacing is 0.34nm. For the bromobenzene functionalized ...

Embodiment 2

[0044] A method for preparing functionalized graphene by ball milling, comprising the steps of:

[0045] Add 0.3 grams of flake graphite and 6 grams of p-bromoaniline into a 100ml ball mill jar. The grinding balls are two kinds of mixed stainless steel grinding balls with a diameter of 5mm and 10mm. The volume ratio of the grinding balls to the raw materials is 1:0.25. After fully mixing, Then add 7.2 grams of isoamyl nitrite, then fix it on a ball mill with a rotating speed of 500 rpm and a ball milling time of 12 hours. The obtained product was washed and separated, and then dried at 60° C. to obtain a graphene powder whose surface was functionalized with bromobenzene. Carry out XRD and SEM detection to it, its test effect is similar to embodiment 1. The successful preparation of bromobenzene-functionalized graphene could be demonstrated.

Embodiment 3

[0047] A method for preparing functionalized graphene by ball milling, comprising the steps of:

[0048] Add 0.3 grams of flake graphite and 3 grams of p-bromoaniline into a 100ml ball milling tank. The grinding balls are two kinds of mixed stainless steel grinding balls with a diameter of 3mm and 12mm. The volume ratio of the grinding balls to the raw materials is 1:0.5. After fully mixing, Then add 3.6 grams of isoamyl nitrite, then fix it on a ball mill with a rotating speed of 450 rpm and a ball milling time of 20 hours. The obtained product was washed and separated, and then dried at 60°C. Carry out XRD and SEM detection to it, its test effect is similar to embodiment 1. The successful preparation of bromobenzene-functionalized graphene could be demonstrated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com