Preparation method of magnetic attapulgite molecularly imprinted material

A technology of attapulgite and molecular imprinting, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of time-consuming and complicated operation, difficulty in realizing rapid separation and continuous production, etc. The effect of high reuse times, improved stability and reusability, and reduced false positive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

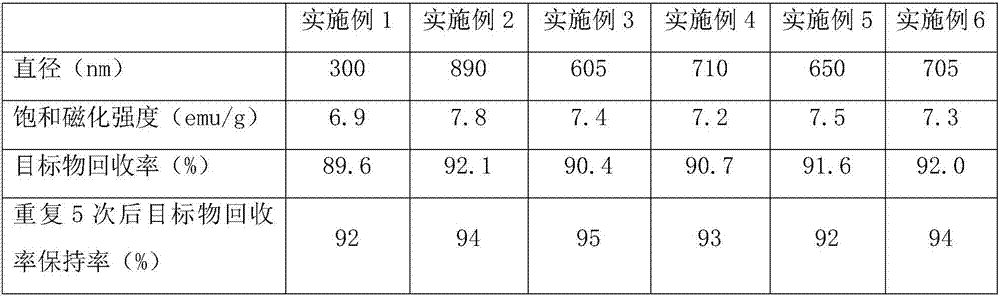

Examples

Embodiment 1

[0026] (1) 2.7g ferric chloride and 7.2g sodium acetate are dissolved in 100mL ethylene glycol, form uniform yellow solution, according to the mol ratio of ferric chloride, carboxylated carbon nanotubes and attapulgite is 2: 0.5:4, add carboxylated carbon nanotubes and attapulgite, ultrasonically disperse under the protection of nitrogen, transfer to a polytetrafluoroethylene-lined autoclave, react at 200 ° C for 8 h, cool naturally to room temperature, wash with ethanol Wash with deionized water and dry in vacuum at 60°C to obtain magnetic particles.

[0027] (2) Disperse 0.1 g of magnetic particles in 90 mL of ethanol aqueous solution, mix ultrasonically, add 10 mL of ammonia water and 5 mL of tetraethyl orthosilicate dropwise in sequence, stir at room temperature for 24 h, wash and separate, and disperse in purified toluene after vacuum drying. Under nitrogen protection, 4 mL of alkenyl silane modifier and 6 mL of triethylamine were added, refluxed for 24 hours, washed and ...

Embodiment 2

[0030] (1) The ferric chloride of 2.7g and 7.2g sodium acetate are dissolved in 100mL ethylene glycol, form uniform yellow solution, be 5 according to the mol ratio of ferric chloride, carboxylated carbon nanotube and attapulgite: 1:8, add carboxylated carbon nanotubes and attapulgite, ultrasonically disperse under nitrogen protection, transfer to a polytetrafluoroethylene-lined autoclave, react at 200°C for 8 hours, cool naturally to room temperature, and wash with ethanol Wash with deionized water and dry in vacuum at 60°C to obtain magnetic particles.

[0031] (2) Disperse 0.1 g of magnetic particles in 90 mL of ethanol aqueous solution, mix ultrasonically, add 10 mL of ammonia water and 5 mL of tetraethyl orthosilicate dropwise in sequence, stir at room temperature for 24 h, wash and separate, and disperse in purified toluene after vacuum drying. Under nitrogen protection, 4 mL of alkenyl silane modifier and 6 mL of triethylamine were added, refluxed for 24 hours, washed a...

Embodiment 3

[0034] (1) The ferric chloride of 2.7g and 7.2g sodium acetate are dissolved in 100mL ethylene glycol, form uniform yellow solution, be 3 according to the mol ratio of ferric chloride, carboxylated carbon nanotube and attapulgite: 0.6:6, add carboxylated carbon nanotubes and attapulgite, ultrasonically disperse under nitrogen protection, transfer to a polytetrafluoroethylene-lined autoclave, react at 200°C for 8 hours, cool naturally to room temperature, and wash with ethanol Wash with deionized water and dry in vacuum at 60°C to obtain magnetic particles.

[0035] (2) Disperse 0.1 g of magnetic particles in 90 mL of ethanol aqueous solution, mix ultrasonically, add 8 mL of ammonia water and 2 mL of tetraethyl orthosilicate dropwise in sequence, stir at room temperature for 24 h, wash and separate, and disperse in purified toluene after vacuum drying. Under nitrogen protection, 5 mL of alkenyl silane modifier and 6 mL of triethylamine were added, refluxed for 24 hours, washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com