Water treatment system and method for three-dimensional-electro-fenton treatment for triclocarban

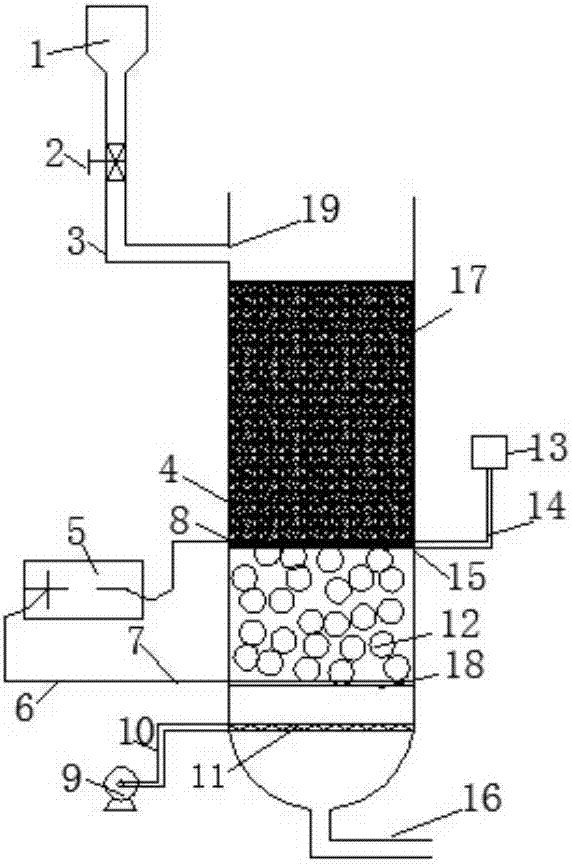

A water treatment system, the technology of triclocarban, is used in water/sewage treatment, special compound water treatment, biological water/sewage treatment, etc. It can solve the problems of increased cost, secondary pollution, and inability to form continuous treatment, and achieve Reduce costs, enhance effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

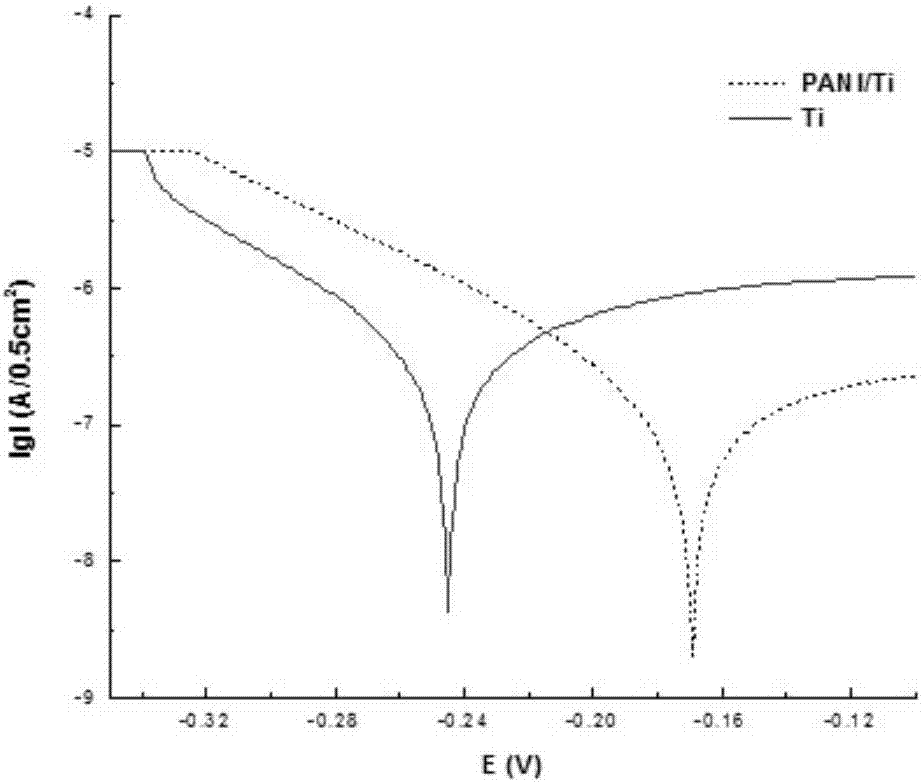

[0057] The preparation method of PANI / Ti anode is:

[0058] S01: The porous titanium mesh polished with sandpaper of different thicknesses was washed with NaOH solution at 95°C for 1 hour, acid washed with HCl solution at 90°C for 1 hour, rinsed with deionized water, and then dried in a blast drying oven. Dry at 105°C for later use.

[0059] S02: Add 0.06 parts of sodium dodecyl sulfonate, 0.12 parts of n-butanol, and 10 parts of a mixture of butyl acrylate and ethanol to 30 parts of deionized water and magnetically stir until it is in the form of a transparent microemulsion. Use hydrochloric acid to adjust the pH The value was adjusted to 1, and 3 parts of aniline monomer was added dropwise to obtain a homogeneous solution.

[0060] S03: Under nitrogen and ice-water bath conditions, slowly add 10 parts of ammonium persulfate solution dropwise to the homogeneous solution obtained in the above step S02, and the dropping process lasts for 40 minutes to slowly initiate the polym...

Embodiment 2

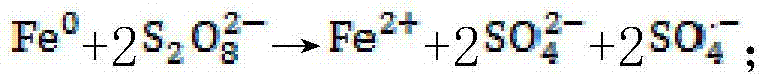

[0064] The difference between this embodiment and the above-mentioned embodiment 1 is that the gold tailings-based Co / Fe in this embodiment 0 The preparation method of particle electrode 12 is:

[0065] Fully soak the gold tailings, ultrasonically clean them for 2 hours, dry them at 110°C for 6 hours, cool to room temperature, put them in a ball mill and grind them into powder, and use an 80-mesh sieve to sieve the gold tailings powder; then accurately Weigh parts by weight: 55 parts of gold tailings powder aggregate, 12 parts of sodium chloride pore-forming agent, 15 parts of cement binder, Co, Fe 0 20 parts of active components, mixed well, rolled into balls (diameter between 3-5mm), and then placed in a constant temperature incubator at 35°C for 8 days to obtain stable gold tailings-based Co / Fe 0 Particle electrode 12 .

Embodiment 3

[0067] The difference between this embodiment and the above-mentioned embodiment 1 is that the gold tailings-based Co / Fe in this embodiment 0 The preparation method of particle electrode 12 is:

[0068] Fully soak the gold tailings, ultrasonically clean them for 2 hours, dry them at 115°C for 3 hours, cool to room temperature, put them in a ball mill and grind them into powder, and use an 80-mesh sieve to sieve the gold tailings powder; then accurately Weigh parts by weight: 65 parts of gold tailings powder aggregate, 8 parts of sodium chloride pore-forming agent, 25 parts of cement binder, Co, Fe 0 15 parts of active components, mixed thoroughly, rolled into balls (with a diameter of 3-5mm), and then placed in a constant temperature incubator at 30°C for 10 days to obtain a stable gold tailings-based Co / Fe 0 Particle electrode 12 .

[0069] In other embodiments of the present invention, the device of the water treatment system can also be of other structures, for example, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com