Polyester reclaimed material recycling method

A technology for recycling materials and polyester, applied in recycling technology, plastic recycling and other directions, can solve the problem of high TVOC content in recycled polyester, avoid the production of diethylene glycol, improve depolymerization efficiency, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

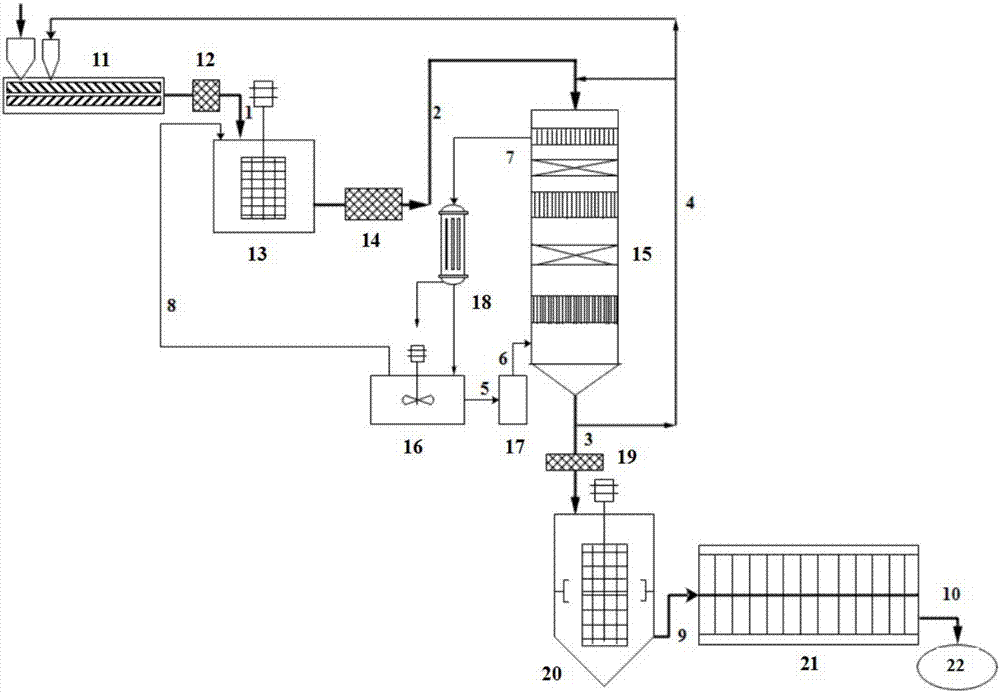

[0057] A kind of recycling method of polyester recycled material, such as figure 1 As shown, the steps are as follows:

[0058] 1) Add polyester oligomer melt with a moisture content of 50ppm, a catalyst and a polyester oligomer melt with an average degree of polymerization of 2 into a twin-screw extruder for reactive melt blending, and obtain an average degree of polymerization of The preliminary depolymerization melt of 40, wherein, the mass ratio of polyester reclaimed material and polyester oligomer melt is 1:1, and catalyzer is ethylene glycol titanium, with respect to the polyester oligomer with respect to the metal element quality in the catalyzer Calculated by melt mass, the content of catalyst is 50ppm; the temperature of reactive melt blending is: the temperature of twin-screw feed section is 268°C, the temperature of twin-screw compression section is 288°C, the temperature of homogenization section is 288°C, and the time is 2min. For nitrogen protection;

[0059] ...

Embodiment 2

[0071] A method for recycling recycled polyester, the steps are as follows:

[0072] 1) The polyester oligomer melt with a moisture content of 90ppm, a catalyst and an average degree of polymerization of 1.5 is added to a twin-screw extruder for reactive melt blending, and the average degree of polymerization obtained after the reaction is The preliminary depolymerization melt of 20, wherein, the mass ratio of polyester reclaimed material and polyester oligomer melt is 0.1:1, and catalyst is tetra-n-butyl titanate, and the metal element quality in catalyst is lower than polyester Calculating the mass of the polymer melt, the content of the catalyst is 50ppm; the temperature of the reactive melt blending is: the temperature of the twin-screw feed section is 260°C, the temperature of the twin-screw compression section is 275°C, the temperature of the homogenization section is 275°C, and the time is 5min. The atmosphere is nitrogen;

[0073] 2) The preliminary depolymerization m...

Embodiment 3

[0082] A method for recycling recycled polyester, the steps are as follows:

[0083] 1) Add polyester oligomer melt with a moisture content of 80ppm, a catalyst and an average degree of polymerization of 4 polyester oligomers into a twin-screw extruder for reactive melt blending, and obtain an average degree of polymerization of The preliminary depolymerization melt of 30, wherein, the mass ratio of polyester reclaimed material and polyester oligomer melt is 3:1, and catalyst is tetraisopropyl titanate, and the metal element quality is lower than polyester in the catalyst Calculated by polymer melt mass, the content of catalyst is 10ppm; the temperature of reactive melt blending is: the temperature of twin-screw feed section is 275°C, the temperature of twin-screw compression section is 300°C, the temperature of homogenization section is 295°C, and the time is 1min. The vacuum environment where the gauge pressure inside the screw is 0.1KPa;

[0084] 2) The preliminary depolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com