Brake pad material for high-speed railway train and preparation method thereof

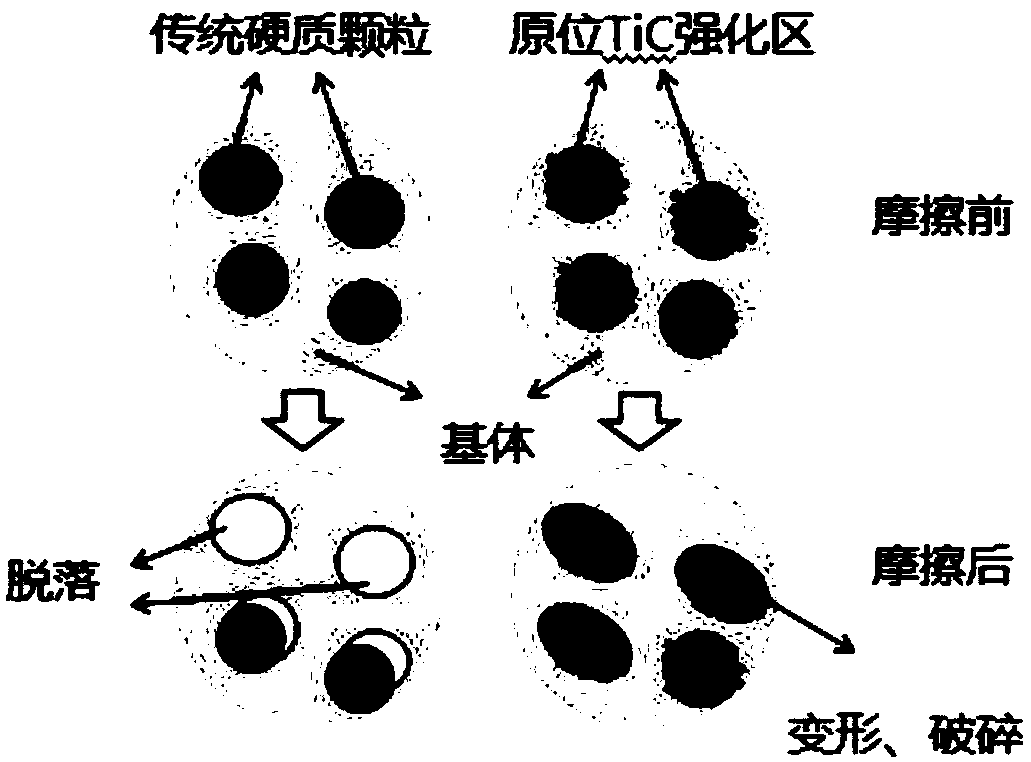

A technology for brake pads and high-speed railways. It is used in mechanical equipment, friction linings, metal processing equipment, etc. It can solve the problems of insufficient interface bonding strength, hard particles falling off, and increased wear rate, and achieve excellent performance. , the effect of low wear rate and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Ti 2 The preparation method of AlC powder

[0047] Mix titanium powder, aluminum powder and carbon black according to the molar ratio of 3:1.4:0.8, and then ignite under the protection of no pressure and inert gas to synthesize Ti with a stoichiometric ratio of 2:1:0.7 through a self-propagating process 2 AlC powder.

[0048] 2. Preparation method of binder

[0049] The binder consists of 95% by mass of kerosene and 5% by mass of dialkyl phosphates. The binder is added according to 1%-5% (mass) of the total mass of the raw material powder.

[0050] It is found through tests that the effect of adding 5% (mass) of the total mass of the raw material powder is the best. The binder prepared according to the above ratio solves the problem of difficult mixing of copper and graphite caused by uneven density, and at the same time, there is almost no residue after volatilization at high temperature. Among them, the role of kerosene is a binder, and the role of dialkyl pho...

Embodiment 2

[0061] Illustrate effect of the present invention by following experiment:

[0062] In this embodiment, brake material is prepared according to the following specific formula and the best implementation mode, and the specific formula is shown in Table 1.

[0063] The best implementation mode of the preparation method of brake sheet material in embodiment 1 is:

[0064] 1) Mixing: Put the raw material powder into the mixing machine after drying, sieving and weighing, spray into the binder, and mix for 2 hours;

[0065] 2) Prefabricated compact: put the raw materials mixed in step 1) into a steel abrasive tool for pressing, with a load of 400MPa;

[0066] 3) Sintering: In a reducing atmosphere, heat up to a sintering temperature of 980°C at a rate of 10°C / min, pressurize to 30MPa at the same time, keep the temperature for 2h, keep the pressure at the same time for 0.5h, then reduce the pressure to 1MPa, and the heat preservation is over After cooling with the furnace, when the...

Embodiment 3

[0078] The difference between this embodiment and Experiment 2 in Embodiment 2 is that the preparation method of the brake pad material is different, and the others are the same as Experiment 1, and the specific preparation method is:

[0079] 1) Mixing: use wet mixing, dry the raw material powder, sieve and weigh it, put the raw material powder into the mixer, spray into the binder, and mix for 2 hours;

[0080] 2) Prefabricated compact: put the raw materials mixed in step 1) into a steel abrasive tool for pressing, with a load of 300MPa;

[0081] 3) Sintering: Carry out sintering in a reducing atmosphere, raise the temperature to a sintering temperature of 850°C at a heating rate of 10°C / min, pressurize to 30MPa at the same time, keep the temperature for 1h, keep the pressure for 0.5h while keeping the temperature, then reduce the pressure to 1MPa, and keep the temperature Cool with the furnace after the end, and unload the pressure when the furnace temperature is lower than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com