Beneficiation wastewater treatment method

A technology for mineral processing wastewater and a treatment method, which is applied in the field of reducing organic matter and suspended solids in mineral processing wastewater and industrial wastewater treatment, can solve the problems of difficult control of suction volume, unstable operation, low work efficiency, etc., to reduce one-time investment and The effect of operating costs, flexible and convenient operation management, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

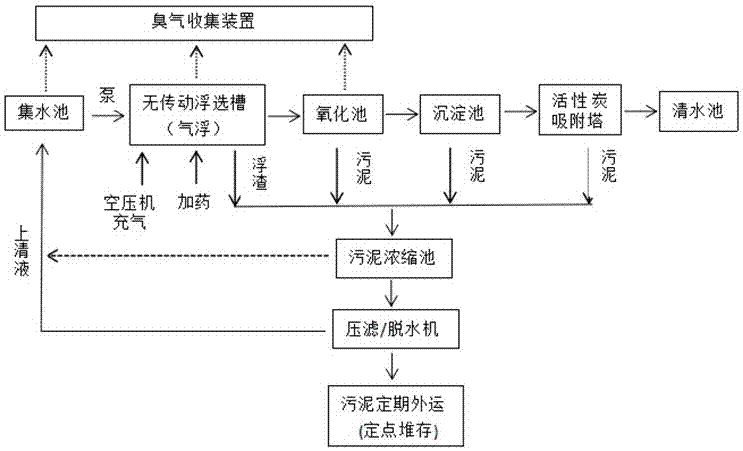

Method used

Image

Examples

Embodiment 1

[0039]The COD content in the wastewater of an iron ore dressing plant is 680mg / L, the suspended solids SS content is 1000mg / L, and the pH value is 9.0. In order to reduce the COD and SS content and achieve the purpose of recycling, the treatment process includes sump aeration, no transmission Flotation tank air flotation, chemical oxidation, flocculation sedimentation, activated carbon adsorption and other steps, the specific steps are as follows:

[0040] (1) Waste water enters the sump, and an aeration pipe network is laid on the bottom of the sump, and a blower is used for forced aeration, and the aeration volume is controlled at an air-to-water ratio of 5:1. A primary sedimentation tank is set at the rear end of the aeration tank.

[0041] (2) Use the water pump to pump the precipitated supernatant into the non-transmission flotation tank at a uniform speed for air flotation, further remove SS in the wastewater, keep the pH value at 9.0, and use the dosing system to add PA...

Embodiment 2

[0051] The COD content in the wastewater of a bauxite dressing plant is 680mg / L, the suspended matter SS content is 1000mg / L, and the pH value is 8.5. In order to reduce the COD and SS content to achieve the purpose of recycling, the wastewater treatment process of the dressing plant and the embodiment 1 is similar, except that:

[0052] (1) Keep the original pH value at 8.5;

[0053] (2) Deodorization collection and treatment device without step (6);

[0054] (3) In step (3), only compounded COD remover is added to the oxidation tank, without deodorant, and the type and dosage of the compounded agent are specially made according to the characteristics of the wastewater of the dressing plant. The oxidation time is 3h.

[0055] The treated wastewater of the dressing plant has a COD content of 50mg / L, a suspended solid SS content of 40mg / L, and a removal rate of 92.65% and 96.00%, respectively, which can be fully recycled without affecting production indicators. The specific i...

Embodiment 3

[0059] The COD content in the wastewater of a molybdenum ore dressing plant is 1800mg / L, the suspended solids SS content is 550mg / L, and the pH value is 8.0. In order to reduce the COD and SS content to achieve the purpose of recycling, the wastewater treatment process of the dressing plant is the same as that in Example 1 Similar, but the difference is: the type and amount of compound chemicals added to the oxidation tank in step (3) are specially made according to the characteristics of the waste water of the dressing plant, and the oxidation time is 2.5h. After treatment, the COD content is 80mg / L, the suspended solid SS content is 50mg / L, and the removal rates are 95.55% and 90.91% respectively, which can be fully recycled without affecting the production indicators. The specific indicators are shown in Table 3.

[0060] Table 3 The average indicators of wastewater treatment in a molybdenum ore dressing plant in Henan

[0061] Detection Indicator

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com