Method for preparing fine-crystalline and high-strength magnesia alumina spinel transparent ceramic

A technology for magnesia-alumina spinel and transparent ceramics, which is applied in the preparation field of enhancing the mechanical strength of magnesia-alumina spinel transparent ceramics, which can solve the problem of grain growth, grain boundary micro-cracks, and reduce the strength of magnesia-alumina spinel transparent ceramics And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the present invention, the preparation method of the fine-grained, high-strength magnesia-alumina spinel transparent ceramics includes the steps of powder treatment, molding, sintering and annealing. The preparation method of the fine-grained, high-strength magnesium-aluminum spinel transparent ceramic provided by the present invention is exemplarily described below.

[0030] The powder treatment is to mix magnesium aluminum spinel powder with a certain amount of rare earth metal oxide (RE 2 o 3) or / and the precursor of the rare earth metal oxide by ball milling (wherein, the rotation speed may be 300 rpm, and the time may be 4-12 hours), and then the powder is sieved. The chemical formula of the commercial magnesium-aluminum spinel raw material powder can be expressed as MgO·nAl 2 o 3 , n=1˜1.5, preferably 1˜1.1. The particle size of the magnesium aluminum spinel powder can be 50-200nm, and the purity can be ≥99.9%. Adopted RE 2 o 3 Containing at least one of...

Embodiment 1

[0036] Powder treatment: Weigh 80g of magnesia-aluminum spinel powder, use ethanol as the dispersion medium, and high-purity alumina balls as the ball milling medium. After ball milling at a speed of 300 rpm for 6 hours, place the slurry in an oven at 60°C Dry in medium for 12 hours, then pass through 80 mesh sieve;

[0037] Molding: The calcined powder is formed by dry pressing (20MPa, holding pressure for 20 seconds) combined with cold isostatic pressing (200MPa, holding pressure for 5 minutes) to obtain magnesium aluminum spinel ceramic green body;

[0038] Sintering: Put the formed green body in a muffle furnace for 8 hours at 800°C and then pre-sinter it in a vacuum furnace at 1525°C for 6 hours. Static pressure sintering, holding time is 4 hours;

[0039] Annealing heat treatment: heat the sample sintered by hot isostatic pressing in a muffle furnace at 1250° C. for 10 hours.

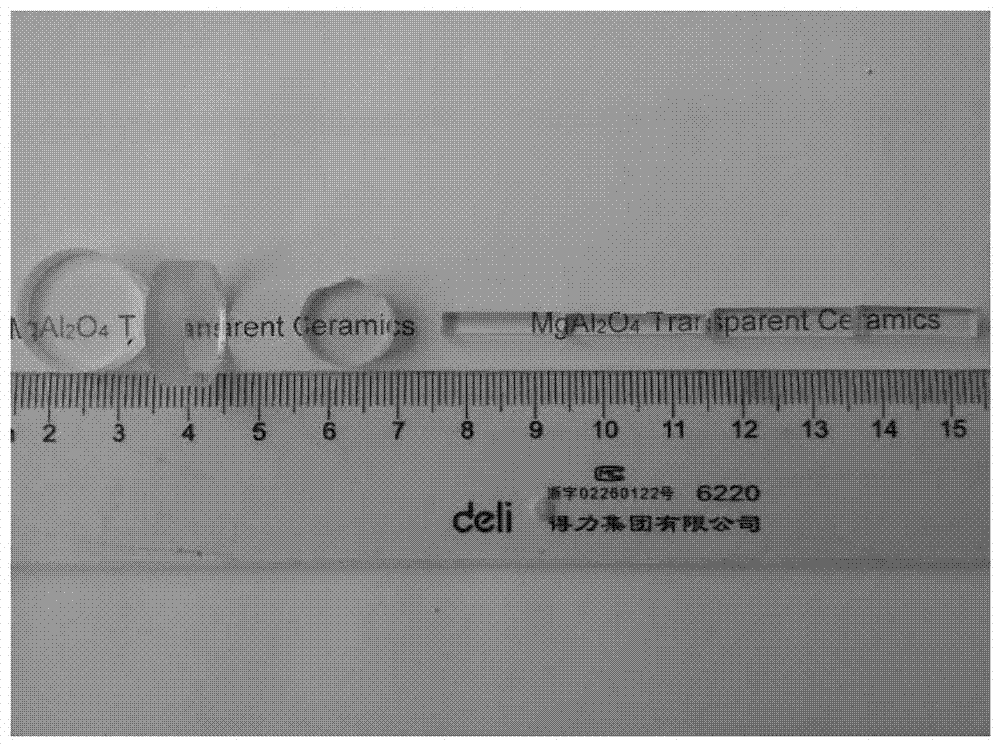

[0040] figure 1 The magnesia-aluminum spinel transparent ceramic photo obtained by the meth...

Embodiment 2

[0043] The preparation process is similar to that of Example 1, the difference is that when weighing the powder, in addition to weighing 80g of magnesium aluminum spinel powder, it is also necessary to weigh 0.008g (100ppm) Y 2 o 3 , The process of powder treatment, molding and bisque firing is the same as in Example 1. The bisque-fired sample was pre-fired in a vacuum furnace at a sintering temperature of 1550°C for 6 hours, and then the pre-fired sample was sintered by hot isostatic pressing at a sintering temperature of 1600°C and a pressure of 196 MPa for 4 hours.

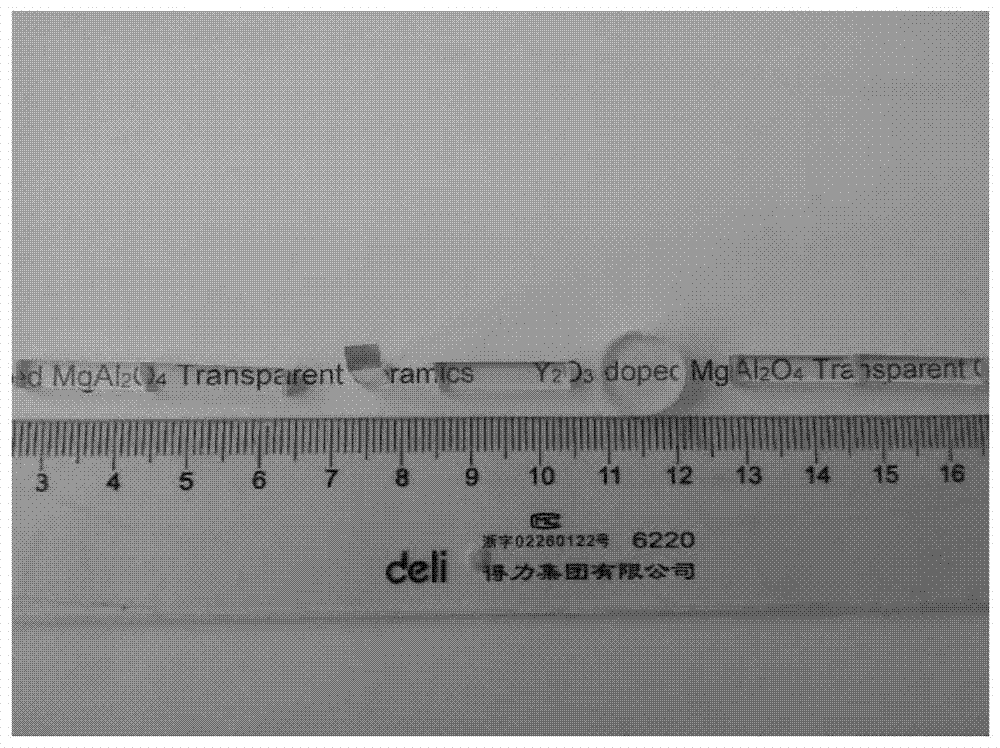

[0044] image 3 For the doping 100ppm Y that embodiment 2 makes 2 o 3 Photograph of a magnesia-alumina spinel transparent ceramic sample after double-sided polishing, courtesy of image 3 It can be seen that the prepared doped Y 2 o 3 The sample has good optical transparency in the visible light range, and the optical uniformity is very good;

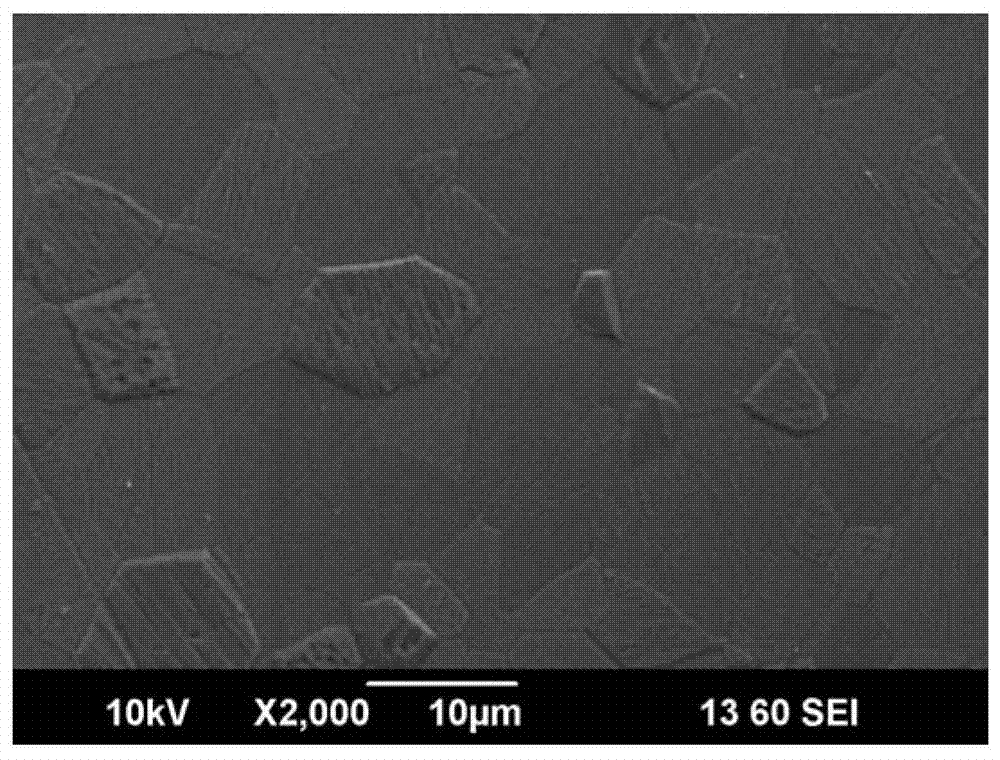

[0045] Figure 4 For the surface and cross-section SEM phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com