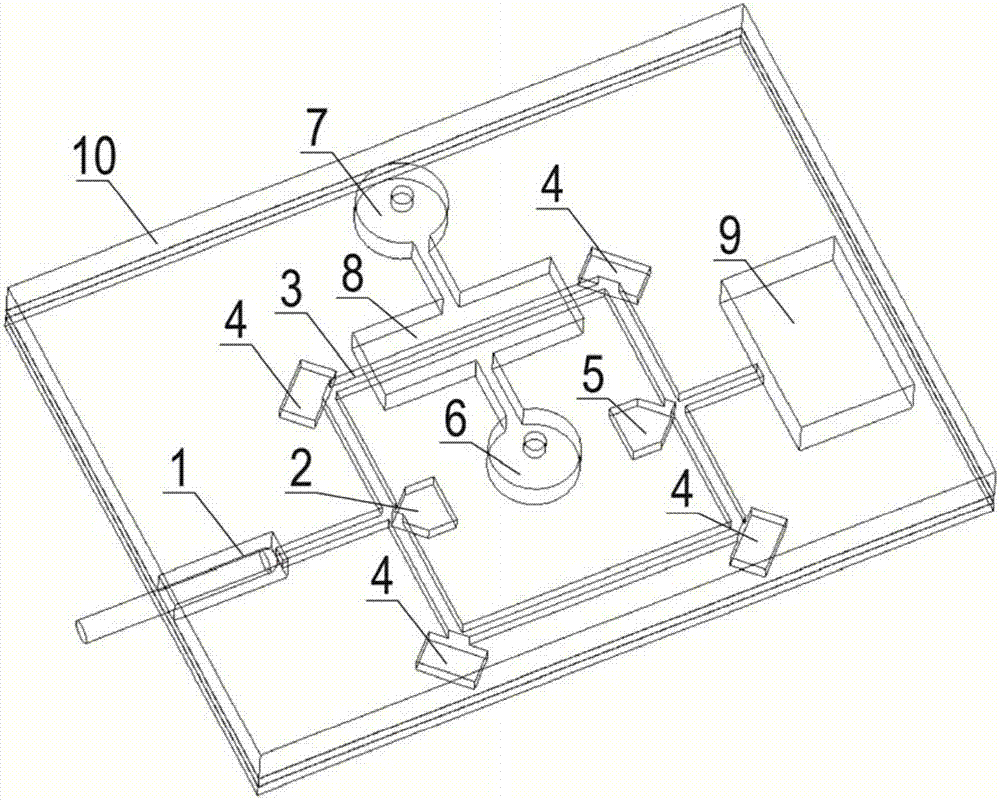

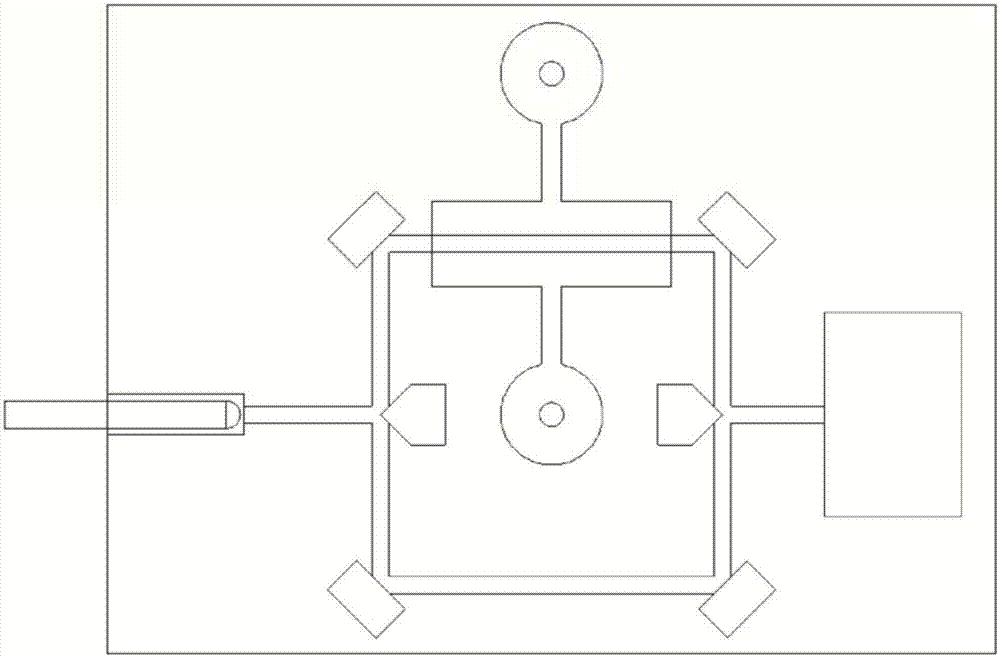

Integrated biochemical sensor based on rib optical waveguide

A biochemical sensor and optical waveguide technology, applied in the field of optical biochemical sensing, can solve the problems of unfavorable integration of on-chip systems, large overall size, long interference structure, etc., and achieve the effects of high detection sensitivity, low cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

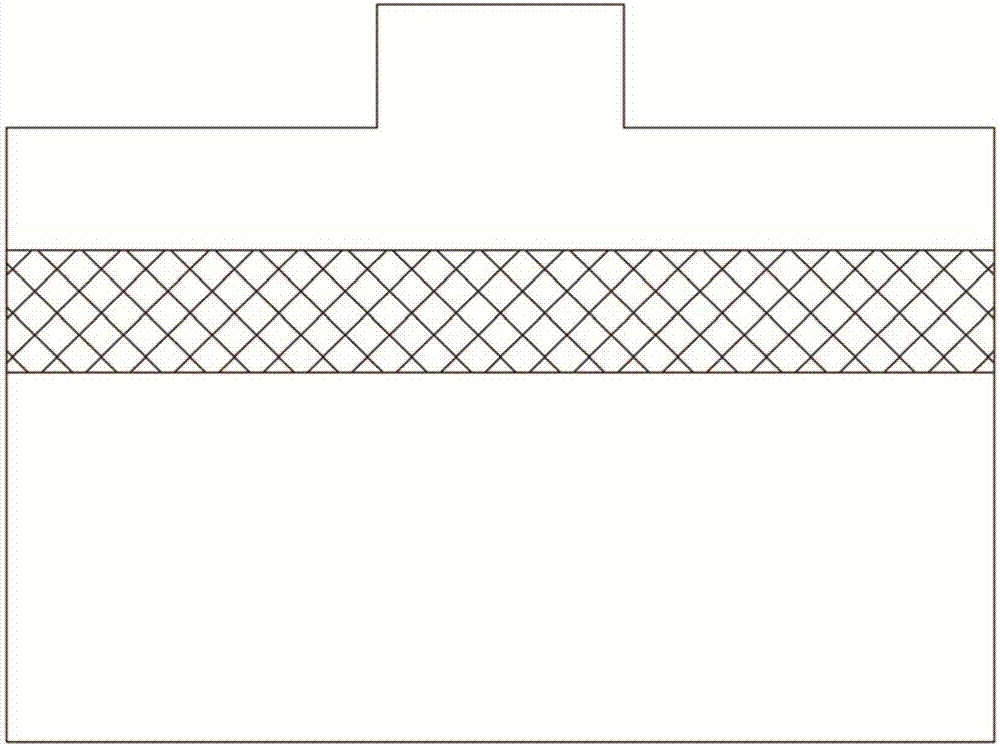

[0044] A silicon-on-insulator (SOI) with a silicon thickness of 10 μm on the top layer, a silicon oxide thickness of 2 μm on the insulating layer, and a silicon-on-insulator (SOI) thickness of 475 μm was selected as the manufacturing material. Ridge waveguide and air groove structures were obtained by deep ultraviolet exposure and inductively coupled plasma dry etching. Such as Figure 4 As shown, the real-time protein solution concentration detection system is composed of a tunable laser at the input end and a single-mode optical fiber. After calibration, the photodetector is used to measure the intensity of the outgoing light to test the protein concentration of the sample.

example 2

[0046] Such as Figure 5 As shown, the above detection system is arrayed, with multiple integrated biochemical sensors (MZI sensor 1, MZI sensor 2, MZI sensor 3...MZI sensor n); monochromatic lasers can be used instead of tunable lasers, and a variety of wavelength of light λ 1 , lambda 2 , lambda 3 ... λ n . At the same time, a plurality of photodetectors PD1, PD2, PD3...PDn are used together. Through the array of the detection system, the measurement of the emitted light intensity of the analyte is realized, and the quantitative analysis of the solution change is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com