Preparation method of self-assembled composite nanofiltration membrane for water softening

A composite nanofiltration membrane and self-assembly technology, which is applied in the field of separation membranes, can solve the problems of complicated operation and long time consumption, and achieve the effect of good hydrophilic performance, convenient operation and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare a dopamine solution with a concentration of 2g / L, adjust its pH to about 8 with Tris-HCl buffer solution, and prepare a concentration of 2g / L, 2.5g / L, 3g / L, 3.5g / L, 4g / L, 5g / L polyethyleneimine casting solution. Take 5 polyethersulfone ultrafiltration membranes, soak them in 2g / L polyethyleneimine casting solution for 15 minutes, then wash them in pure water for 3 minutes, soak them in dopamine solution after drying, self-polymerize and compound them in an oven at 50°C for 18 hours, and then Fully wash in pure water for 4 hours, after drying, soak in 2g / L, 2.5g / L, 3g / L, 3.5g / L, 4g / L, 5g / L polyethyleneimine casting solution for 15min, Wash for another 3 minutes and dry to prepare a self-assembled composite nanofiltration membrane. Store in pure water for testing.

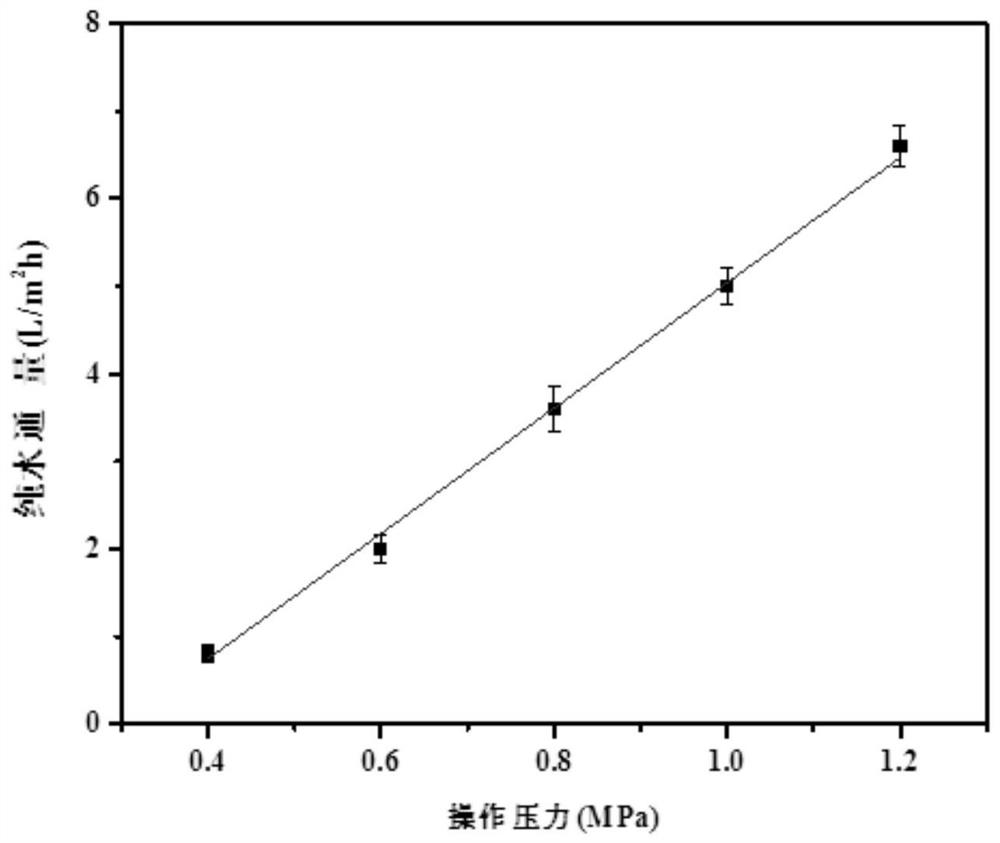

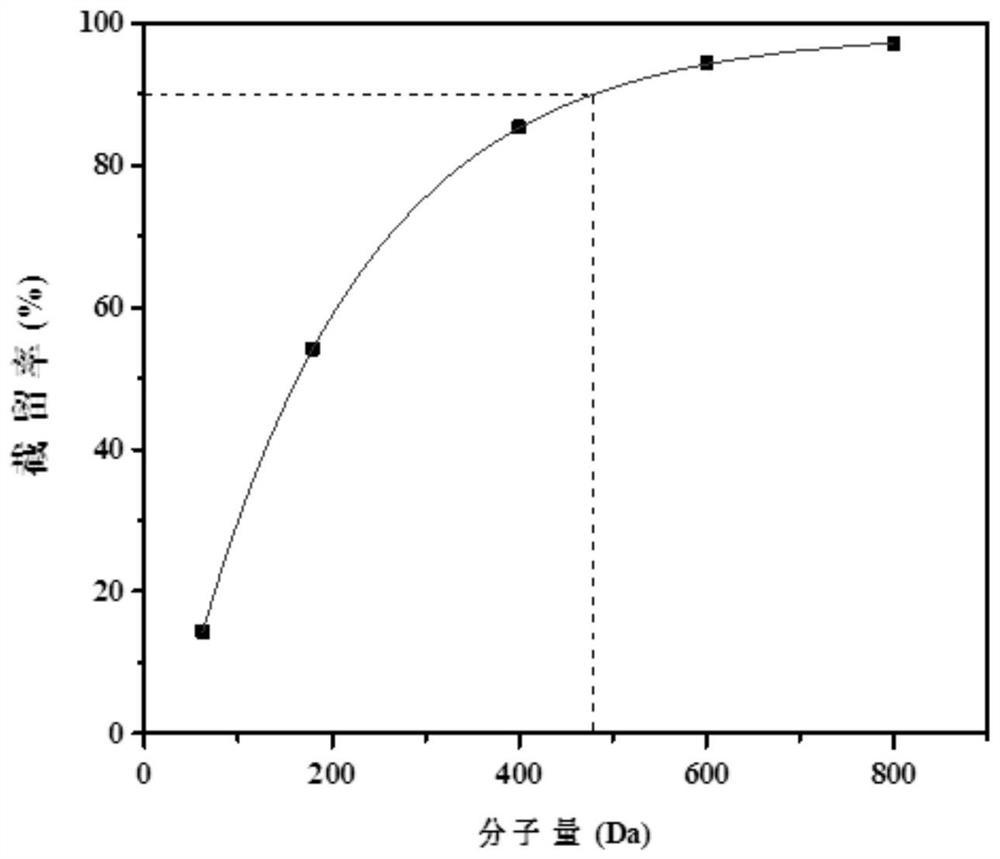

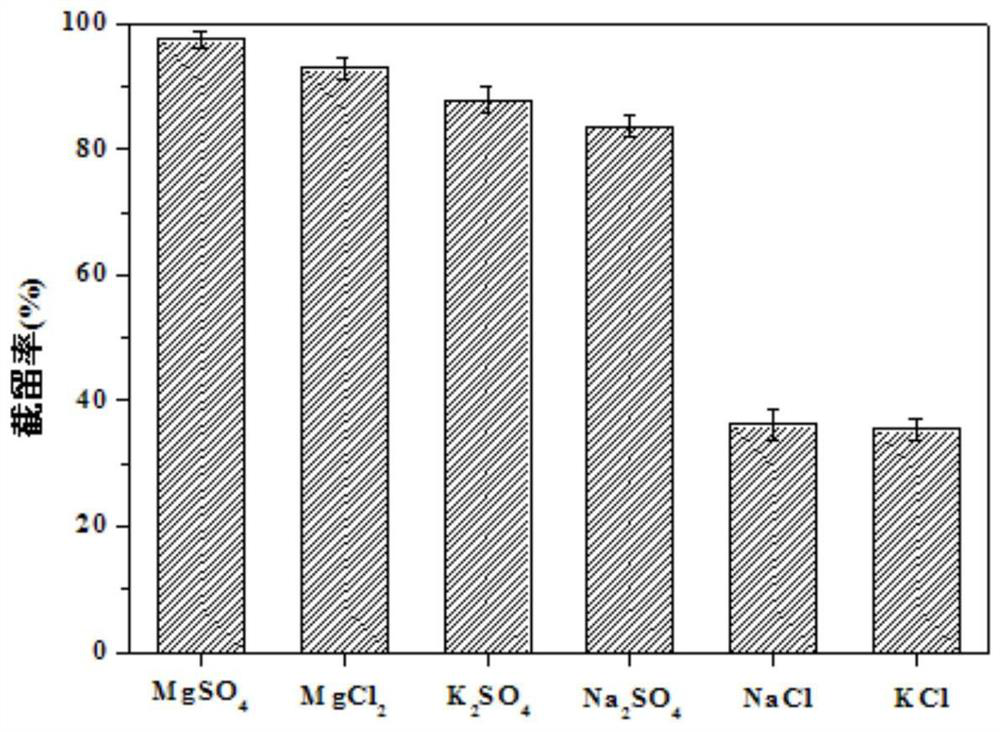

[0027] The prepared composite nanofiltration membranes with polyethyleneimine concentrations of 2g / L, 2.5g / L, 3g / L, 3.5g / L, 4g / L, and 5g / L in the active layer, when the operating pressure is 0.8MPa ...

Embodiment 2

[0029] Prepare the dopamine solution with a concentration of 2g / L, adjust the pH to about 8 with Tris-HCl buffer solution, and polyethyleneimine casting solution with a concentration of 2g / L and 3g / L respectively. Take 5 polyethersulfone ultrafiltration membranes, soak them in 2g / L polyethyleneimine casting solution for 10min, 20min, 30min, 40min, 50min respectively, then wash them in pure water for 3min, dry them and soak them in dopamine solution at 50 Self-polymerization and compounding in an oven at ℃ for 18 hours, then fully washed in pure water for 4 hours, after drying, soak in 3g / L polyethyleneimine casting solution for 10min, 20min, 30min, 40min, 50min, wash for 3min and then dry , the self-assembled composite nanofiltration membrane can be prepared. Store in pure water for testing.

[0030] The prepared polyethyleneimine casting solution soaking time is 10min, 20min, 30min, 40min, 50min composite nanofiltration membrane, under the operating condition of 0.8MPa, the ...

Embodiment 3

[0032] Prepare dopamine solutions with concentrations of 1g / L, 2g / L, and 3g / L, adjust the pH to about 8 with Tris-HCl buffer solution, and polyethylene with concentrations of 1g / L, 2g / L, and 3g / L Imine casting solution. Take 5 polyethersulfone ultrafiltration membranes, soak them in different concentrations of polyethyleneimine casting solution for 30 minutes, wash them in pure water for 3 minutes, soak them in different concentrations of dopamine solutions after drying, self-polymerize and compound them in an oven at 50°C for 18 hours, and then Fully wash in pure water for 4 hours, after drying, soak in 3g / L polyethyleneimine casting solution for 30 minutes, wash for 3 minutes and then dry to prepare self-assembled composite nanofiltration membrane. Store in pure water for testing.

[0033] The prepared polyelectrolyte double layer polyethyleneimine concentration is 1g / L, dopamine concentration 2g / L; polyethyleneimine concentration is 2g / L, dopamine concentration is 1g / L; po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com