Novel clothianidin-containing pesticide fertilizer for preventing and controlling insect diseases and preparation method thereof

A technology for preventing and controlling plant diseases and insect pests and clothianidin, which is applied in the direction of nitrogen fertilizer, potassium fertilizer and phosphate fertilizer, can solve the problems of high toxicity and high residue of pesticides, serious environmental pollution, single insecticidal effect, etc. The effect of long drug period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

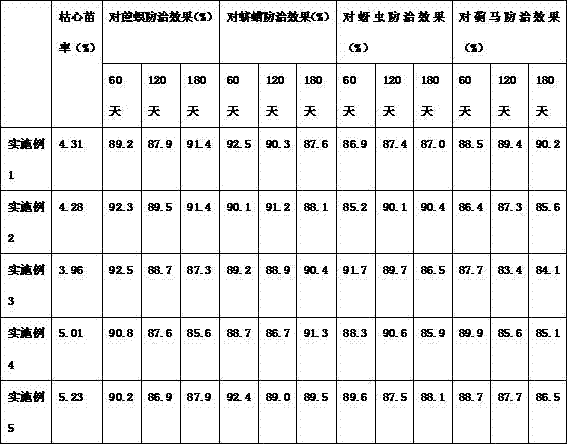

Embodiment 1

[0038] Preparation of organic fertilizer: Add 5 parts of compound fermentation bacteria agent to 70 parts of sugar factory filter mud for fermentation and decomposing, and then mix with 16 parts of urea, 8 parts of monoammonium phosphate, 15 parts of potassium chloride, modified polyaspartic acid resin 12 parts and 4 parts of compound functional bacterial agent are mixed to prepare bio-organic fertilizer.

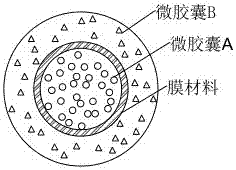

[0039] Microcapsule A preparation: 15 parts of polybutylene succinate solution is put into reactor, add 10 parts of emulsifiers and mix, 1.5 parts of 0.06% clothianidin solution are joined in reactor, at 45 ℃ temperature speed Stir at 800r / min for 30min, stir to allow the capsules to fully absorb the drug, adjust the pH to 10, and shear and disperse for 75 minutes at a temperature of 45°C. Chrysanthemum Microcapsule A;

[0040] Preparation of microcapsule B: 12 parts of chitosan and 13 parts of sodium carboxymethyl cellulose mixed solution were added to the reactor, 1.8 ...

Embodiment 2

[0044] Preparation of organic fertilizer: add 6 parts of compound fermentation bacteria agent to 60 parts of sugar factory filter mud to ferment and decompose, then mix with 15 parts of urea, 5 parts of monoammonium phosphate, 18 parts of potassium chloride, modified polyaspartic acid resin 14 parts and 2 parts of compound functional bacterial agent are mixed to prepare bio-organic fertilizer.

[0045] Microcapsule A preparation: put 11 parts of polycaprolactone acid solution into the reactor, add 13 parts of emulsifier and mix, add 1 part of 0.06% clothianidin solution into the reactor, and rotate at 650r / min at 55°C Stir at low temperature for 20 minutes, stir to allow the capsules to fully absorb the drug, adjust the pH to 8, and shear and disperse for 50 minutes at a temperature of 40°C. Capsule A;

[0046] Preparation of microcapsule B: 13 parts of chitosan and 11 parts of sodium carboxymethyl cellulose mixed solution were added to the reaction kettle, 1.5 parts of 0.06%...

Embodiment 3

[0050] Preparation of organic fertilizer: Add 8 parts of compound fermentation bacteria agent to 63 parts of sugar factory filter mud for fermentation and decomposing, and then mix with 18 parts of urea, 10 parts of monoammonium phosphate, 23 parts of potassium chloride, modified polyaspartic acid resin 13 parts and 3 parts of composite functional bacterial agent are mixed to prepare bio-organic fertilizer.

[0051] Microcapsule A preparation: 10 parts of polybutylene succinate solution is put into reactor, add 12 parts of emulsifiers and mix, 1.2 parts of 0.06% clothianidin solution are joined in reactor, at 40 ℃ temperature speed Stir at 600r / min for 25min, stir to allow the capsules to fully absorb the drug, adjust the pH to 9, and shear and disperse for 65 minutes at a temperature of 60°C. Chrysanthemum Microcapsule A;

[0052] Preparation of microcapsule B: 10 parts of chitosan and 12 parts of sodium carboxymethyl cellulose mixed solution were added to the reactor, 2 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com