Sorting Method of Separation Media in Fluidized Bed Separator

A sorting method and separator technology, applied in the field of sorting, selection of separation media in fluidized bed separators, and size gradation, can solve the problems of reducing the cleaning frequency of heat exchangers, blockage of heat exchangers and air coolers, and catalyst particles. Small diameter and other problems, to achieve good regeneration sorting effect, reduced cleaning frequency, easy to boil and fluidize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

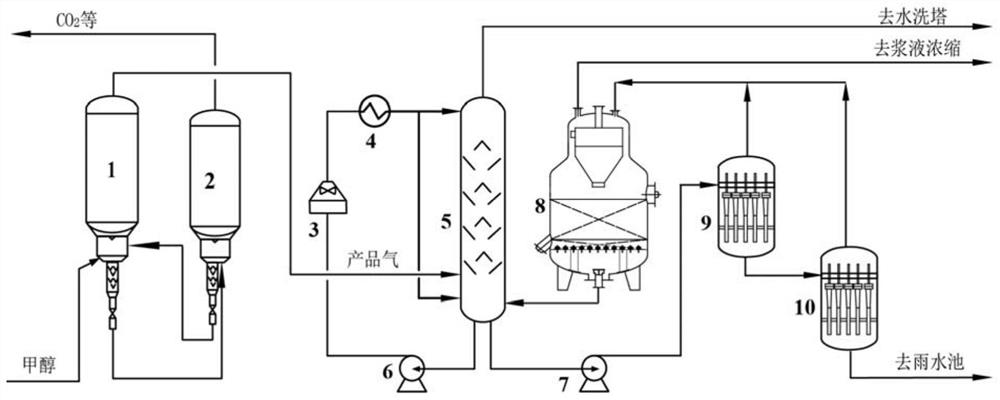

[0092] In the methanol-to-olefin process, a fluidized bed purification device is used to treat the abrasive catalyst particles and oil in the pre-treated process water, so that the treated solid content and oil content reach the standard.

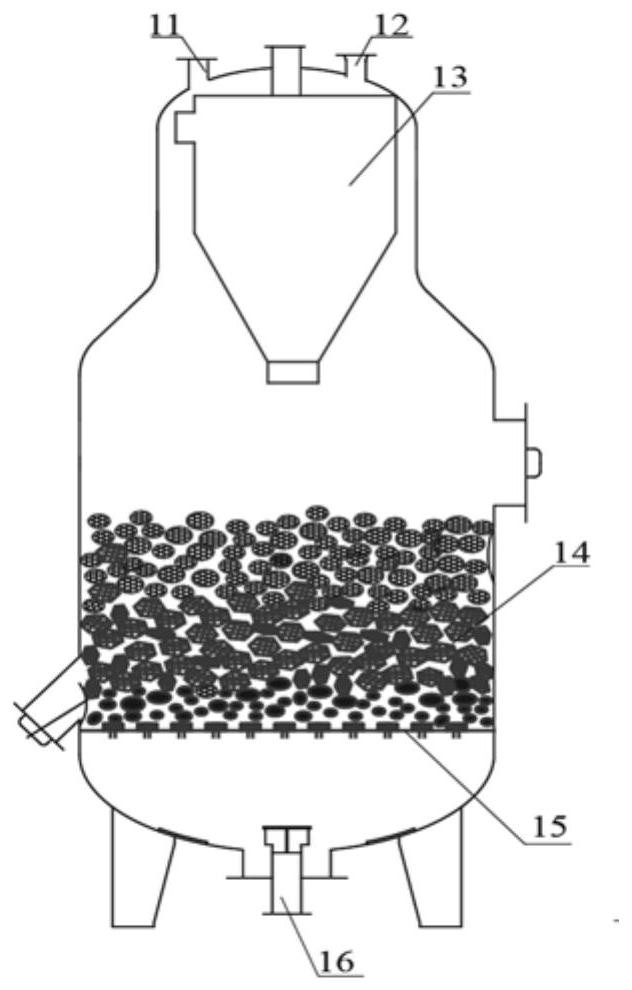

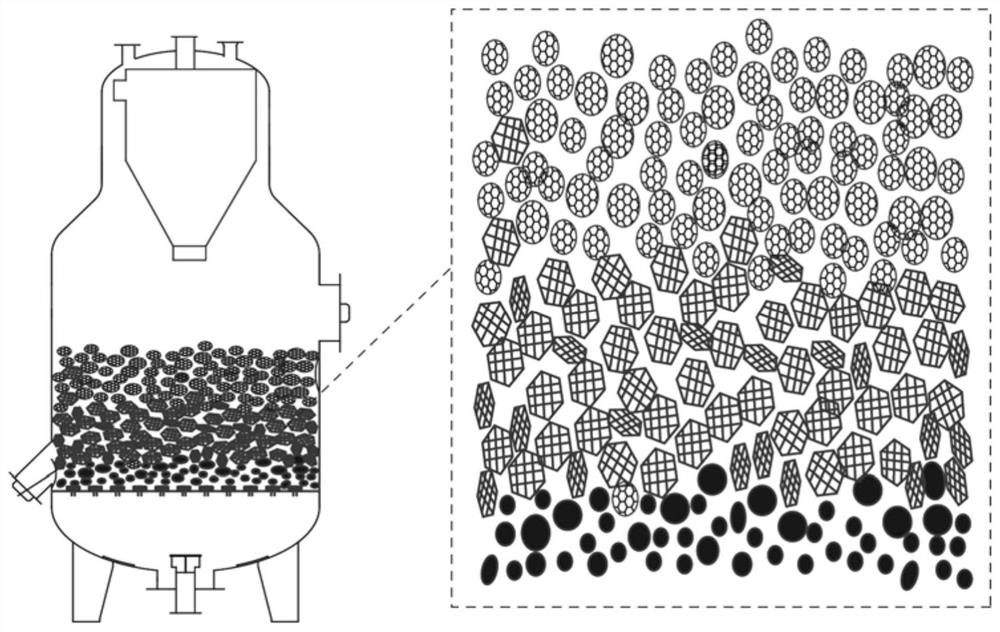

[0093] 1. Setting of the fluidized bed particle bed

[0094] The device has a diameter of 2.5m and a height of about 6m. The top layer of the filter material in the bed is anthracite of 1-2mm, the non-uniformity coefficient is 1.75, the specific gravity is 1.5, the laying thickness is 43cm, accounting for 60% of the total thickness, and the average particle size is d 50 =1.57mm. The intermediate layer filter material is 0.5-0.8mm quartz sand, the non-uniformity coefficient is 1.45, the specific gravity is 2.64, the laying thickness is 23cm, accounting for 32% of the total thickness, and the average particle size is d 50 =0.61mm. The bottom layer of filter material is magnetite of 0.25-0.5mm, the non-uniformity coefficient is 1.69, the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com