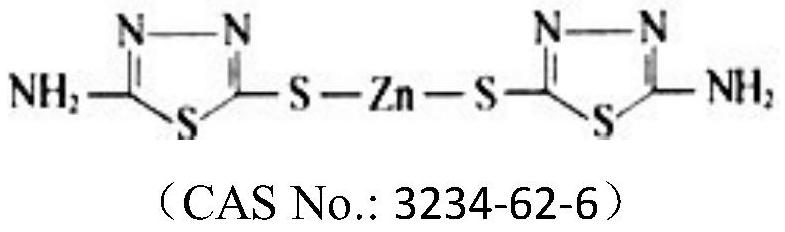

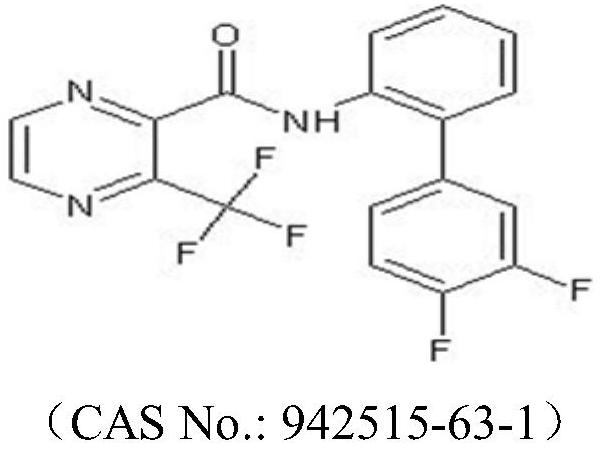

Bactericidal composition containing thiazole zinc and bixafen, its preparation and application

A technology of bixafen and a composition, which is applied in the field of bactericidal compositions containing zinc thiazole and bixafen, and can solve the problems that bactericidal active compounds cannot satisfy plant tolerance and bactericidal activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

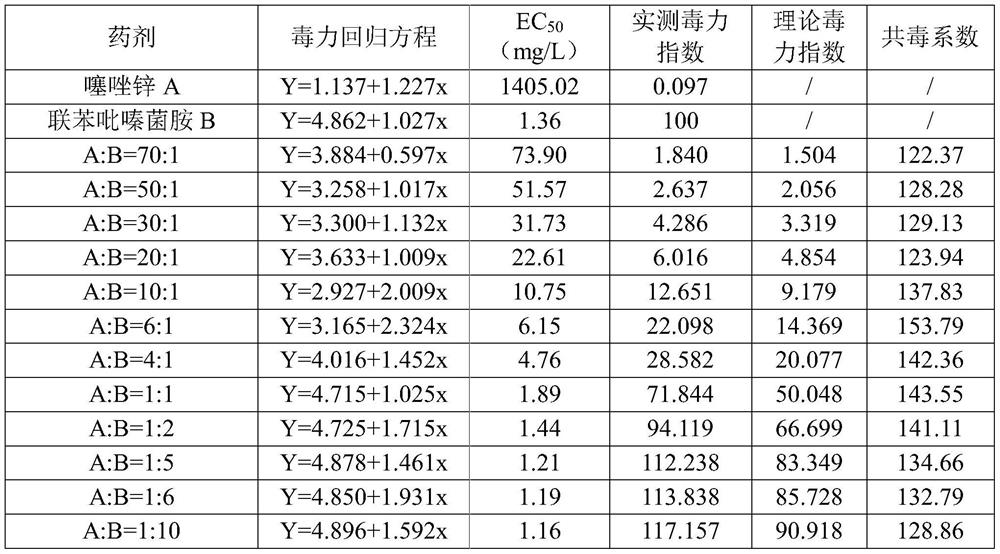

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: 40% (35%+5.0%) suspending agent

[0071] 40% active compound (35.0% thiazole zinc and 5.0% bixafen combination), fatty alcohol polyoxyethylene ether 2.0%, alkylnaphthalene sulfonate 3.0%, sodium methylene dinaphthalene sulfonate 1.0% %, xanthan gum 0.05%, magnesium aluminum silicate 0.6%, glycerol 2.0%, salicylphenyl ester 0.4%, silicone defoamer 0.1%, deionized water to 100%, put into high shear High-speed shearing in a quality emulsifier for 20 minutes, then transported to a sand mill, and circularly sanded for 1-3 times to obtain a suspending agent. The suspension contains 40% active compound.

Embodiment 2

[0072] Embodiment 2: 45% (40.0%+5.0%) suspending agent

[0073] 45% active compound (40.0% thiazole zinc and 5.0% bixafen combination), alkyl naphthalene sulfonate 2.0%, fatty alcohol polyoxyethylene ether sulfate 1.0%, sodium methylnaphthalene sulfonate formaldehyde Condensate 3.0%, sodium starch octenyl succinate 2.0%, glycerin 2.0%, butyl p-hydroxybenzoate 0.2%, polyether defoamer 0.1%, distilled water to 100%, put into high shear High-speed shearing in a quality emulsifier for 25 minutes, then pumped to a sand mill for 90 minutes, and filtered to obtain a suspending agent. The suspension contains 45% active compound.

Embodiment 3

[0074] Embodiment 3: 50% (10.0%+40.0%) suspending agent

[0075] 50% active compound (10.0% thiazole zinc and 40.0% bixafen combination), 1.0% tallow ethoxylated amine salt, 2.0% acyl glutamate, 3.0% polymer polycarboxylate, Dioctyl sulfosuccinic acid sodium salt 1.0%, urea 3.0%, organic silicon defoamer 0.1%, deionized water added to 100%, put into a high-shear homogeneous emulsifier and shear at high speed for 20 minutes, and then Transport it to a sand mill, and circulate the sand for 1-3 times to obtain 50% suspending agent. The suspension contains 50% active compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com