Bagasse-based carbon catalyst, as well as preparation method and application thereof

A technology of carbon catalyst and bagasse, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that bagasse is difficult to be fully utilized, the constituent materials are not single, and environmental pollution, etc., to achieve Environmental protection, no pollution, economic benefits, high production efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

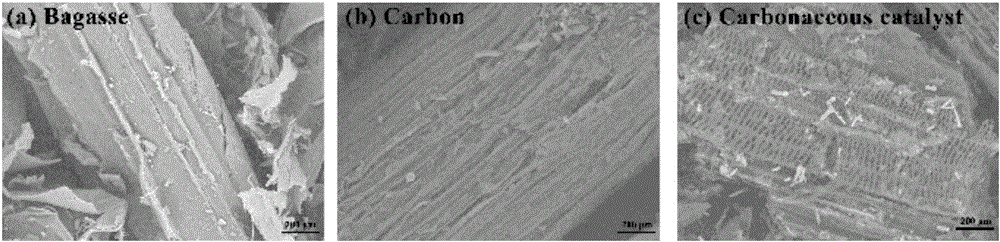

[0037] The preparation of bagasse-based carbon catalyst, concrete steps are as follows:

[0038] 1) Carbonization: use discarded bagasse as raw material, first soak it in clean water, wash it to remove dirt and dust, then wash it with distilled water, and then dry it at 383K to constant weight to make bagasse as a raw material for use. Take 10g of bagasse as a raw material, put it in a porcelain boat, put it into a tubular muffle furnace, raise the temperature to 450K at a heating rate of 5K / min, keep it for 1h, and then cool it down to room temperature naturally. mL / min, to obtain carbonized bagasse;

[0039] 2) Activation: Mix the carbonized bagasse obtained in step 2) with 80 mL of zinc chloride solution (mass fraction: 100 g / L), stir for 24 hours under 298K normal pressure, then suction filter, and dry at 298K for 48 hours , to obtain activated bagasse charcoal;

[0040] 3) Re-carbonization: Put the activated bagasse charcoal obtained in step 3) into a porcelain boat and...

Embodiment 2

[0052] The preparation of the bagasse-based carbon catalyst, the specific steps are the same as in Example 1, except that the mass fraction of zinc chloride in the activation process of step 2) is changed to 130mg / L, and the residence temperature in the re-carbonization process of step 4) is maintained at 973K.

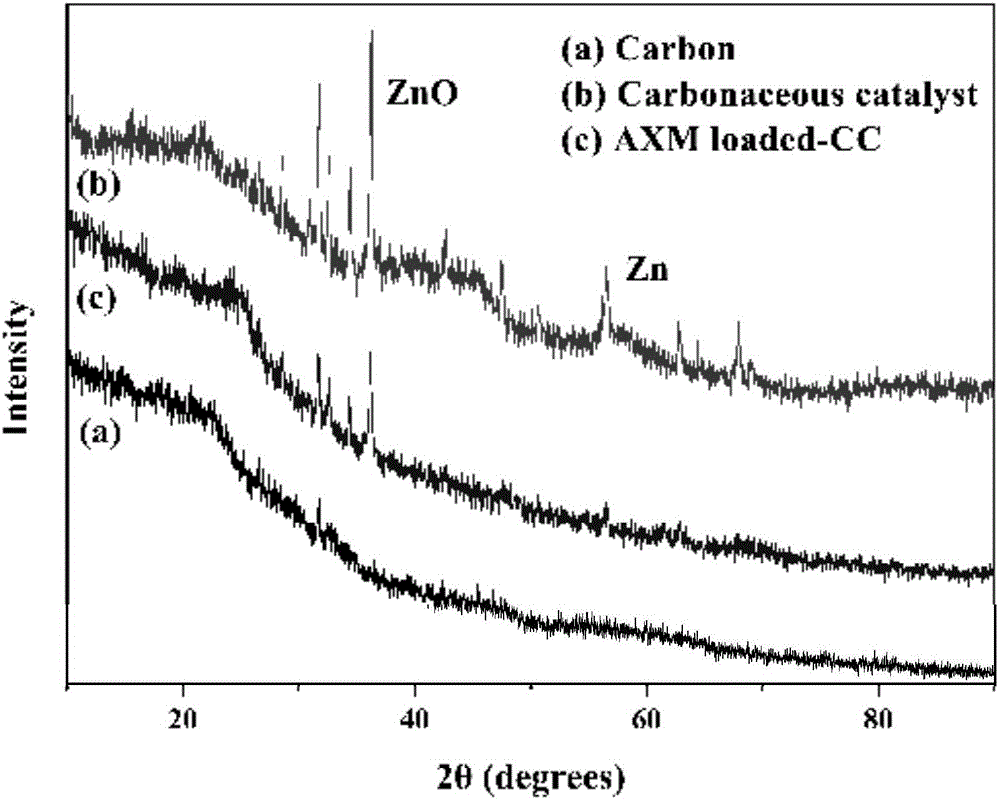

[0053] In the present embodiment, the X-ray diffraction comparison diagram of the carbonized bagasse obtained in step 1) and the finished bagasse-based carbon catalyst obtained in step 3) are as follows figure 2 Shown: Comparing (a) and (b), it can be clearly seen that (b) has obvious peaks around 31-38° and 57°, which proves that ZnO and Zn appear on the catalyst, so the bagasse-based carbon catalyst is successfully prepared .

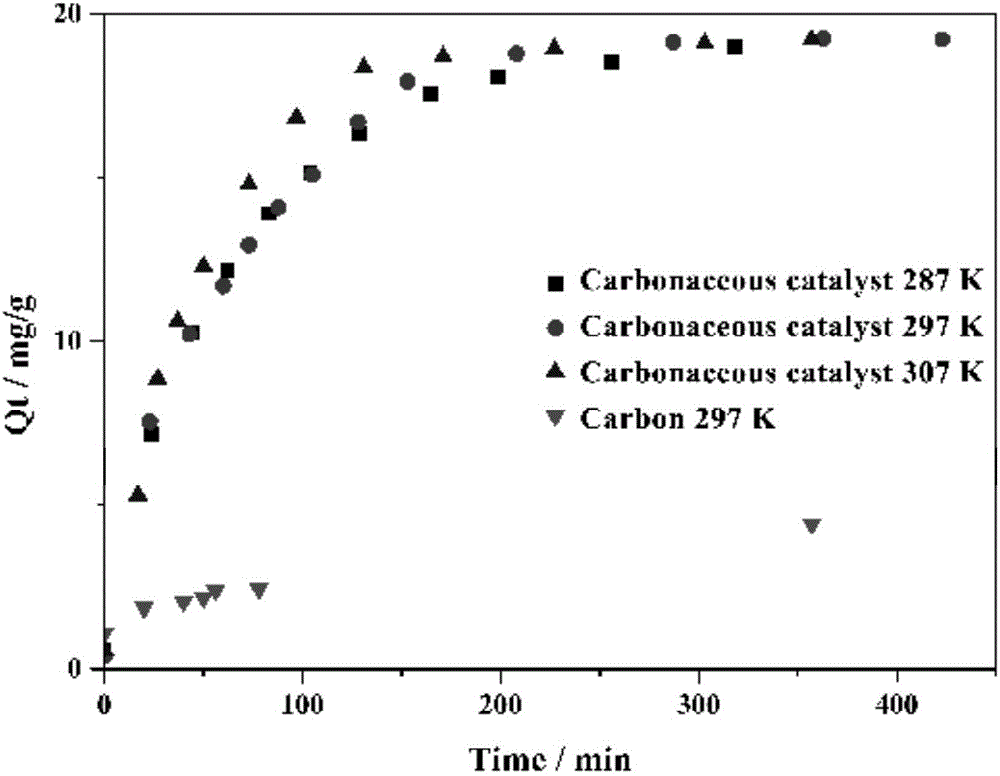

[0054] Measured according to the performance test method described in Example 1, when 0.20 g of the bagasse-based carbon catalyst prepared in this embodiment was treated with 80 mL of 90 mg / L amoxicillin solution at 308 K, the amoxicillin so...

Embodiment 3

[0056] The preparation of the bagasse-based carbon catalyst, the specific steps are the same as in Example 1, except that the carbonization temperature in the re-carbonization process of step 3) is changed to 673K, and the re-carbonization time is 0.75h.

[0057] According to the treatment performance test method described in Example 1, when 0.25 g of the bagasse-based carbon catalyst prepared in this embodiment was treated with 80 mL of 60 mg / L amoxicillin solution at 298 K, the amoxicillin solution was within 6 hours. Reaching a balance, the highest treatment capacity is 18.46mg / g and the highest treatment efficiency can reach 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com