Preparation method of high-polymer flocculatant EA-g-SA (ethyl acrylate-g-succinic anhydride) esterificaiton-oxidation cassava starch

A polymer flocculant and cassava starch technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve problems such as unsatisfactory flocculation effect, achieve excellent flocculation effect, process Safe, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

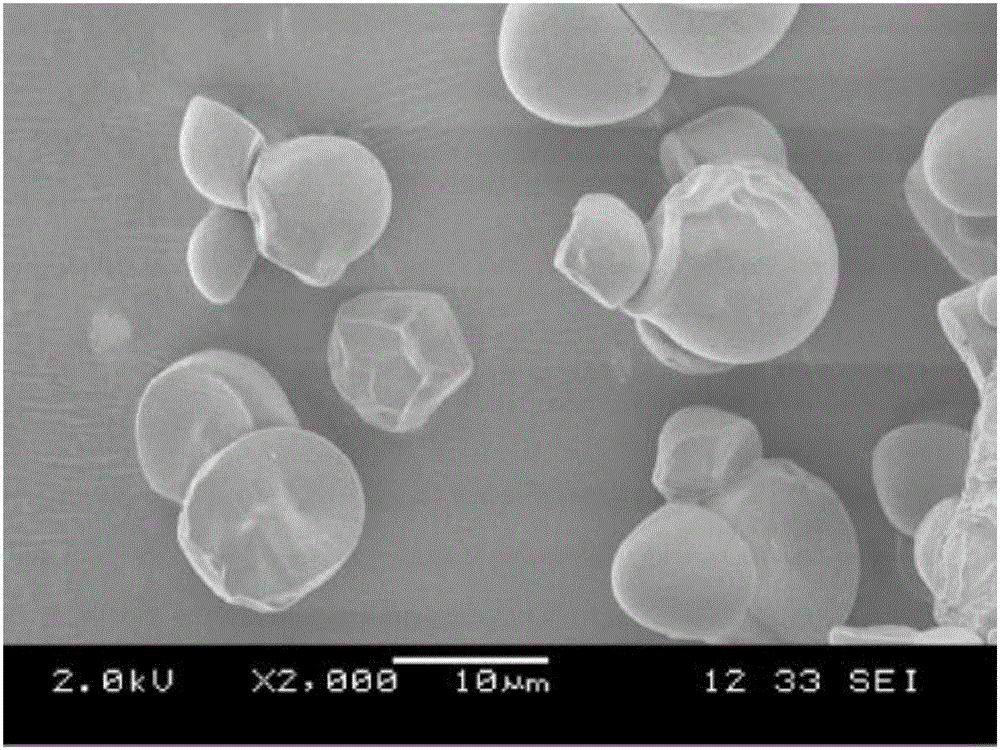

[0053] (1) Weigh 9.0 g of tapioca starch and place it in a vacuum drying oven at 60° C. for 24 hours to constant weight to obtain tapioca starch on a dry basis.

[0054] (2) Weigh 6 g of dry base tapioca starch obtained in step (1) into a 250 mL four-neck flask, add 120 mL of reaction solvent distilled water, stir at room temperature for 15 minutes until uniform, and obtain tapioca starch suspension.

[0055] (3) Heat up the system in step (2) to 55° C., add 0.1 g of ferrous sulfate heptahydrate to the system; stir for 10 minutes and then add 1.8 mL of hydrogen peroxide solution with a mass fraction of 30%, react for 2 hours, and cool to room temperature to obtain the crude product of oxidized starch.

[0056] (4) the crude product obtained in step (3) was centrifuged for 15 minutes at a centrifugal speed of 2500r / min; then filtered through a Buchner funnel, the filter cake obtained was washed 3 times with 25mL mass fraction of 95% ethanol, and then placed Dried in a constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com