Method for preparing sodium antimonate through pressurizing oxidation of sodium salt system

A sodium pyroantimonate system technology, which is applied in the field of preparing sodium pyroantimonate by pressurized oxidation of antimony soot in a sodium salt system, can solve the problem of low leaching rate, achieve low production cost, stable technical indicators, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

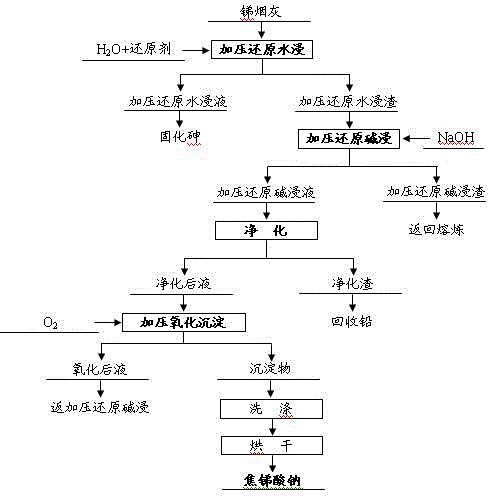

Method used

Image

Examples

Embodiment 1

[0040] The main components of antimony soot are (%) by weight: Sb48.5, As18.4 and Pb5.7. Antimony soot is slurried with water according to the liquid-solid ratio (ratio of water volume L to antimony soot mass kg) 4 / 1, and then starch with 3.5% mass of antimony soot is added, and the mixed slurry is added to a stainless steel high-pressure reactor, Introduce nitrogen to discharge residual air, control the partial pressure of nitrogen to 0.3MPa and ventilate for 2 minutes, then heat up to 175°C and react for 2.0h, when the reaction is completed, cool down and lower the temperature to 60°C, use vacuum filtration to achieve liquid-solid Separation to obtain pressurized reduction water leaching residue and water immersion liquid. The arsenic content decreased to 1.9% after drying the leaching residue in pressurized reducing water, and the removal rate of arsenic reached 93.15%.

[0041] Prepare a sodium hydroxide solution with a concentration of 9.0mol / L, add the above-mentioned p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com