Method for preparing strongly-textured polycrystalline magnetic control shape memory materials through magnetic field assisted directional solidification

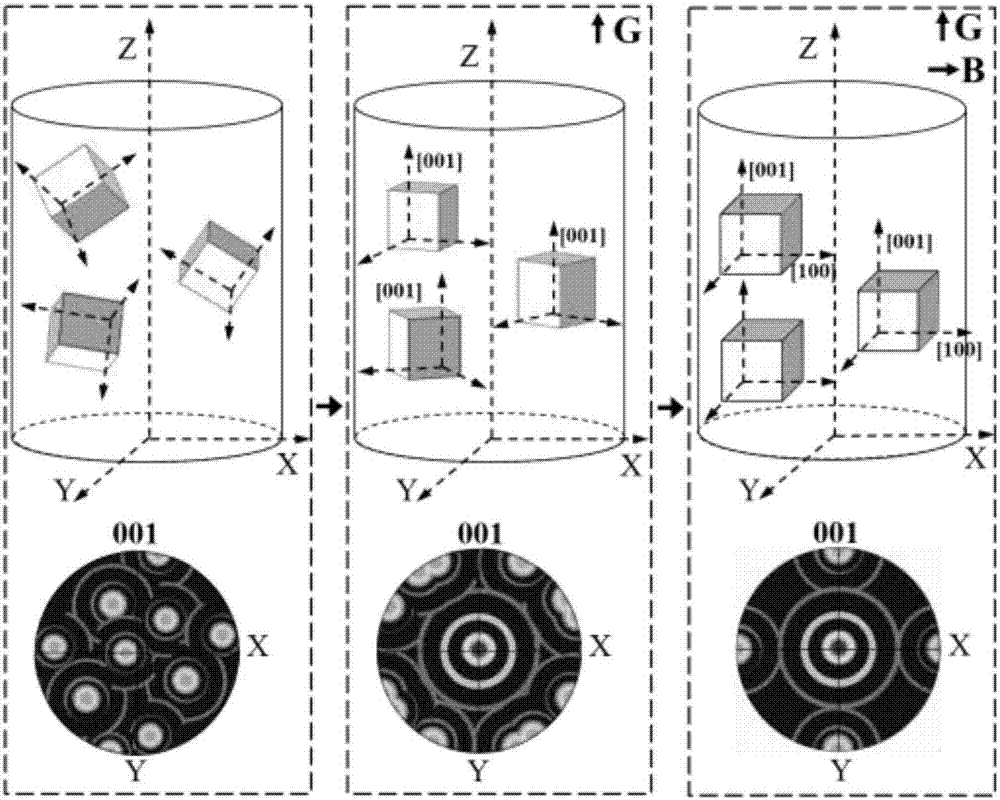

A directional solidification, magnetic field-assisted technology, applied in the preparation of shape memory materials, directional solidification process, and directional solidification to prepare textured polycrystalline magnetron shape memory materials, can solve the loss and weakening of the advantages of intrinsic magnetocrystalline anisotropy Magneto-induced shape memory effect and other problems, to achieve the effect of improving the performance of polycrystalline alloys, improving the magnetic control performance, and promoting high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

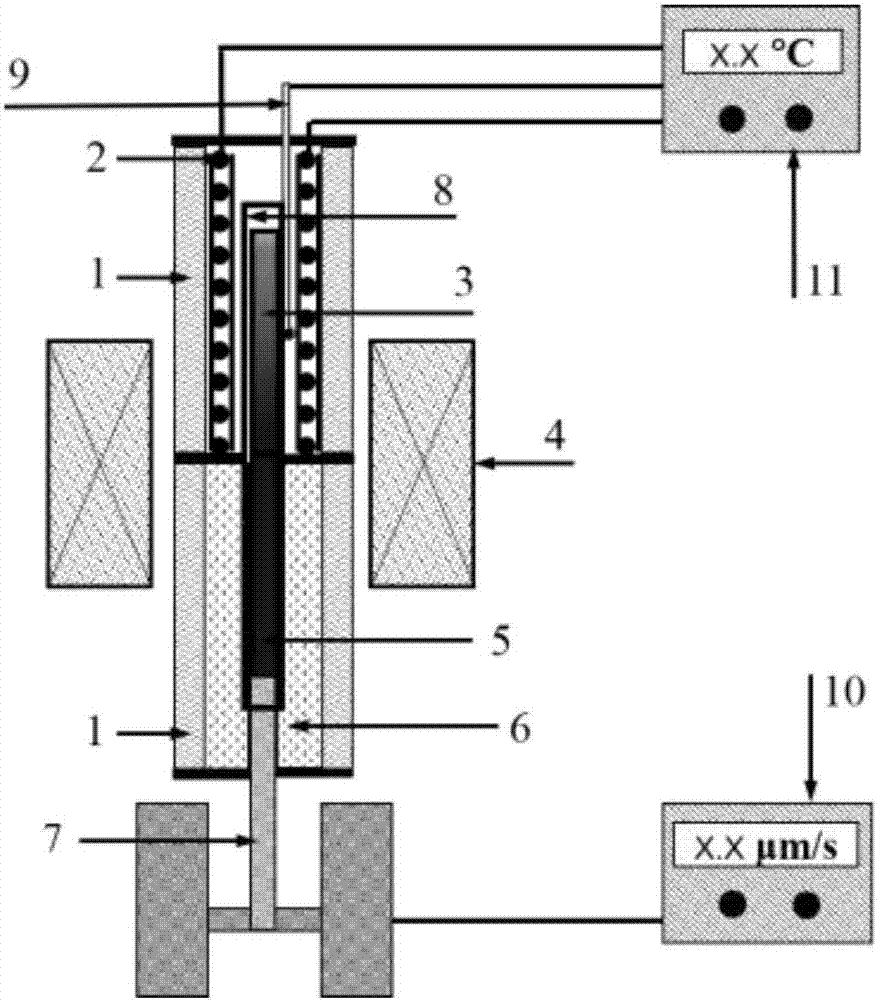

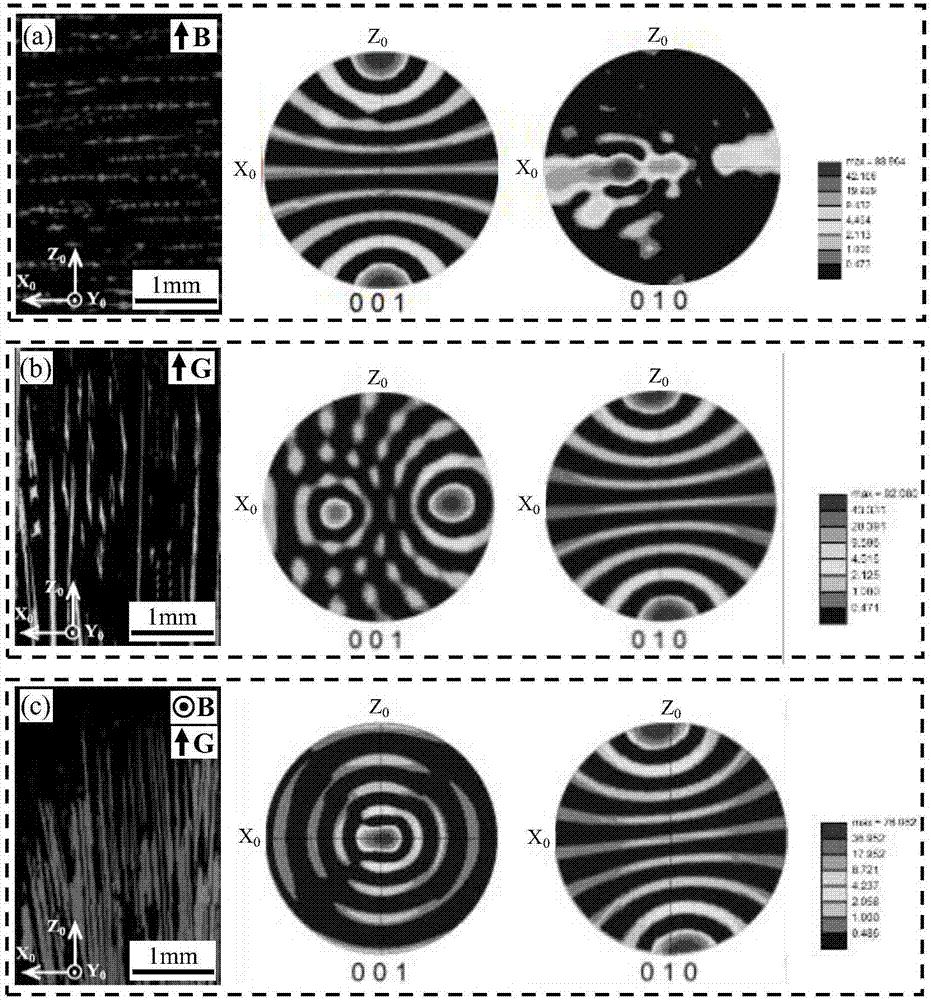

[0030] In this example, see figure 1 and figure 2 , Using a directional solidification device under a transverse magnetic field to implement a magnetic field-assisted directional solidification to prepare a strongly textured polycrystalline magnetically controlled shape memory material Al 3Ni crystals. The directional solidification device under the transverse magnetic field is mainly composed of a traditional Bridgman directional solidification device and a strong magnet 4. The directional solidification device mainly includes a water-cooled casing 1, a heating furnace 2, a quenching pool 6, a pull rod 7, a corundum crucible 8, a thermocouple 9, and a temperature control The device 11 and the pulling speed control device 10, the corundum crucible 8 and the thermocouple 9 placed with the alloy rod sample are arranged in the heating furnace 2, a water cooling sleeve 1 is installed on the outside of the heating furnace 2, and the strong magnet 4 adopts an electromagnet and Se...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

[0046] In this embodiment, the method for preparing a strongly textured polycrystalline magnetically controlled shape memory material through magnetic field-assisted directional solidification includes the following steps:

[0047] a. Raw material preparation of polycrystalline alloy:

[0048] The material is Ni-Mn-Ga alloy, Ni, Mn and Ga metals with a purity of 99.99% are selected, and the required metal raw materials are weighed according to the alloy composition ratio, and the weighed metal raw materials are placed in a vacuum electric arc furnace for melting. Then the alloy ingot is smelted repeatedly for more than 4 times to ensure that the alloy composition is uniform. In the last melting and casting process, the alloy ingot is first melted again, and then sucked into the copper mold under the crucible in the vacuum electric arc furnace to obtain Uniform Ni-Mn-Ga raw alloy rods with a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com