Lepidolite cycling roasting defluorination method

A cyclic roasting furnace, lepidolite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of uneven reaction temperature in the defluorination process, easy melting of materials in the furnace, and large equipment area. and other problems, to achieve the effect of improving energy utilization, less floor space, and low equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

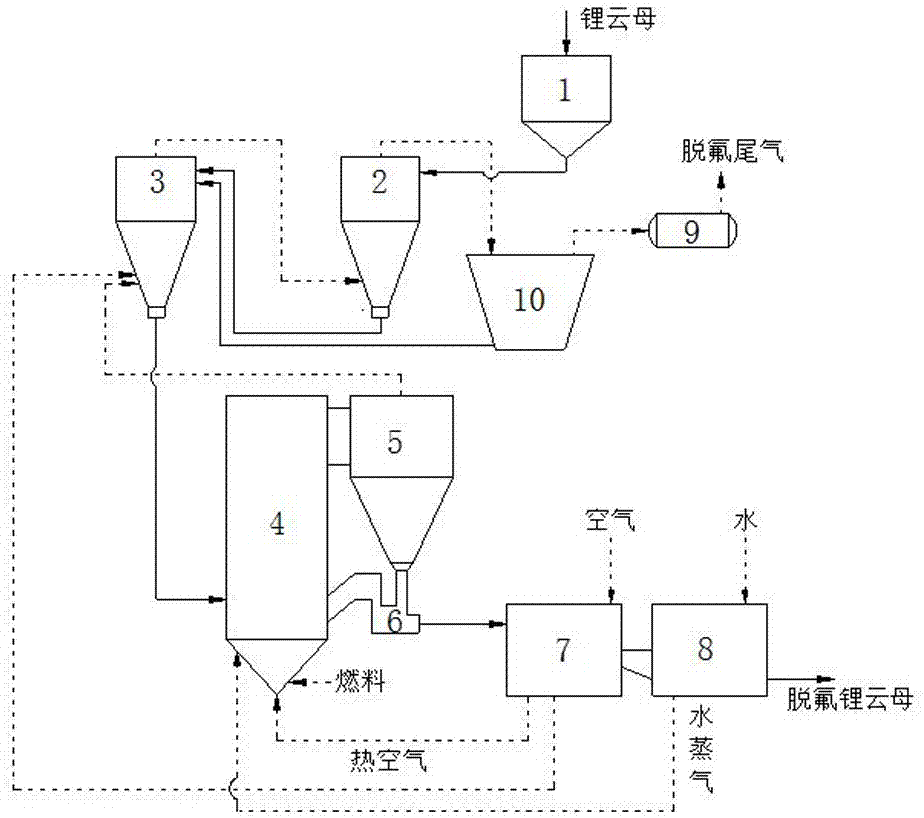

[0026] A method for cyclically roasting and defluorinating lepidolite, the specific steps are:

[0027] Grind the lepidolite ore to a particle size of 800 μm; then put the lepidolite ore powder with a water content of 10wt%, a lithium oxide content of 1.4wt%, and a fluorine content of 2.36wt% into the primary airflow preheater and Drying and preheating are carried out in the secondary airflow preheater. The ore powder in the primary airflow preheater is preheated to 400°C by the hot gas from the outlet of the secondary airflow preheater, and the exhaust gas separated by the primary airflow preheater The fluorine-containing tail gas is obtained after dedusting, and the fluorine-containing tail gas is absorbed and removed by the fluorine-fixing agent CaO. After reaching the environmental protection standard, it is discharged into the atmosphere through a fan; The high-temperature tail gas from the gas-solid separation of the cyclone dust collector is preheated to 700°C; the drie...

Embodiment 2

[0029] A method for cyclically roasting and defluorinating lepidolite, the specific steps are:

[0030] Grind the lepidolite ore to a particle size of 700 μm; then put the lepidolite ore powder with a water content of 8wt%, a lithium oxide content of 3.6wt%, and a fluorine content of 1.16wt% into the primary airflow preheater and Drying and preheating are carried out in the secondary airflow preheater. The ore powder in the primary airflow preheater is preheated to 400°C by the hot gas from the outlet of the secondary airflow preheater, and the exhaust gas separated by the primary airflow preheater Fluorine-containing tail gas is obtained after dust removal; using fluorine-fixing agent K 2 O absorbs and removes fluorine in the fluorine-containing tail gas, and discharges it into the atmosphere through a fan after meeting environmental protection standards; the ore powder in the secondary airflow preheater is preheated to 650°C by the high-temperature tail gas from the gas-soli...

Embodiment 3

[0032] A method for cyclically roasting and defluorinating lepidolite, the specific steps are:

[0033]Grind the lepidolite ore to a particle size of 800 μm; then put the lepidolite ore powder with a water content of 8wt%, a lithium oxide content of 3.6wt%, and a fluorine content of 1.16wt% into the primary preheating separator and Drying and preheating are carried out in the secondary preheating separator, the ore powder in the primary preheating separator is preheated to 400°C by the hot gas from the outlet of the secondary preheating separator, and the exhaust gas separated by the primary preheating separator Fluorine-containing tail gas is obtained after dedusting; the fluorine-containing tail gas is absorbed and removed by the fluorine-fixing agent CaO, and discharged into the atmosphere through a fan after reaching the environmental protection standard; the ore powder in the secondary preheating separator is separated from the gas and solid by the circulating roaster The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com