Photo anode material and preparation and application thereof

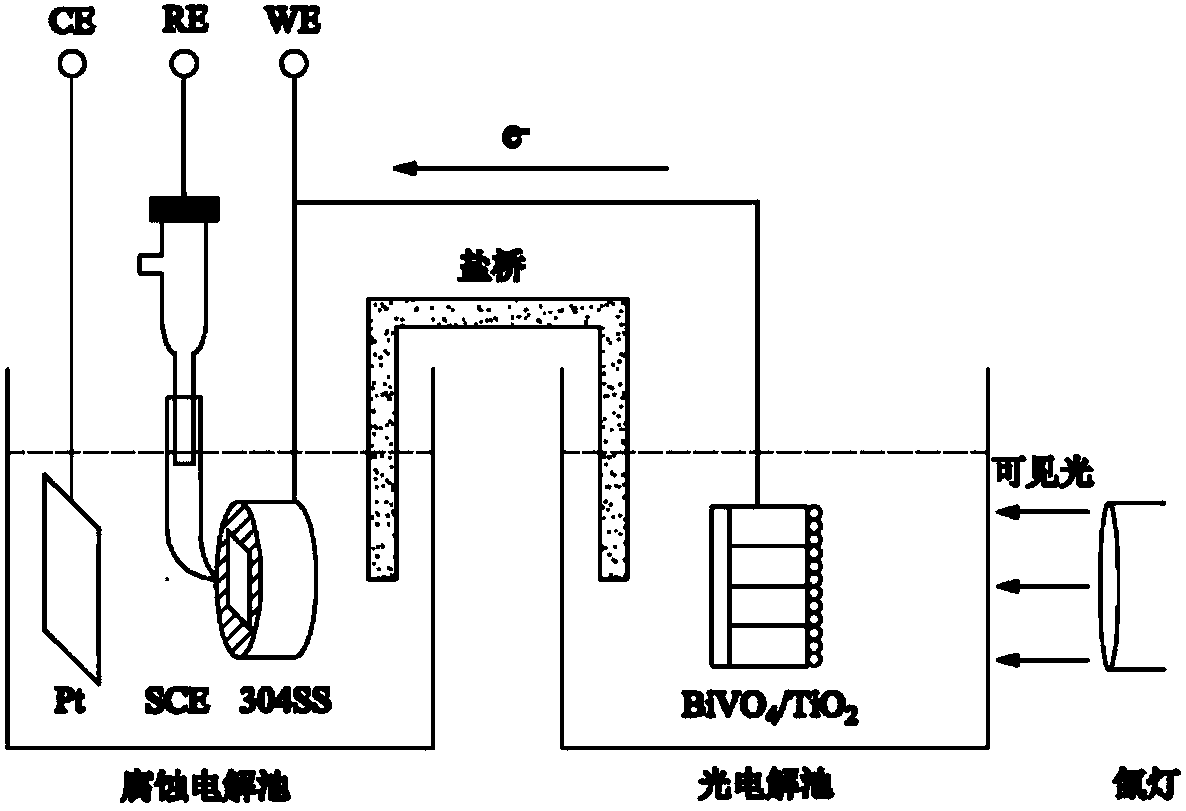

A photoanodic and anodic oxidation technology, which is applied in metal material coating process, nanotechnology for materials and surface science, electrolytic coating, etc., can solve the problem of effective protection of metal, low utilization rate of sunlight and photoelectric efficiency, and photogenerated electrons. and hole recombination rate are too fast to achieve the effect of broadening the absorption range, improving the utilization rate, excellent and stable anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of photoanode includes the following steps:

[0041] Pretreatment of titanium substrate: cut a titanium sheet with a size of 20*15mm from a 0.1mm thick titanium foil (purity greater than 99.9%) as a substrate, then ultrasonically clean it in acetone, anhydrous ethanol and deionized water for 1 min, and then clean it with ethanol , Blow dryer spare. Weigh 0.45g NH 4 F was dissolved in 2.5 mL of deionized water, followed by 6 mL of H 2 O 2 and 6mL of 65-68% concentrated HNO from the market 3 Prepare a polishing solution, put the cleaned titanium sheet in the polishing solution for 1 minute, then wash it with deionized water and ethanol respectively, and dry it for use.

[0042] TiO 2 Nanotube array film preparation: Weigh 0.22g NH 4 F, dissolve in 4 mL of deionized water, sonicate until it is completely dissolved, then add 40 mL of ethylene glycol, and then sonicate until the two phases are completely dissolved, as the working solution. At room temp...

Embodiment 2

[0050] The preparation of photoanode comprises the following steps:

[0051] Pretreatment of titanium substrate: Cut a titanium sheet with a size of 20*15mm from a 0.1mm thick titanium foil (purity greater than 99.9%) as the substrate, and then ultrasonically clean it in acetone, absolute ethanol and deionized water for 1min, and then clean it with ethanol , blow dry with a hair dryer for later use. Weigh 0.45g NH 4 Dissolve F in 2.5mL deionized water, then add 6mL H 2 O 2 and 6mL of 65-68% commercial concentrated HNO 3 Make a polishing solution, put the cleaned titanium sheet into the polishing solution and polish it for 1 min, then wash it with deionized water and ethanol respectively, and dry it for later use.

[0052] TiO 2 Preparation of nanotube array film: weigh 0.22g NH 4 F, dissolved in 4mL deionized water, sonicated until it was completely dissolved, then added 40mL of ethylene glycol, and then sonicated until the two phases were completely dissolved, as a work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com