Tadpole-shaped sulfonated POSS-containing hybrid polymer synthesized proton exchange membrane and preparation method therefor

A proton exchange membrane and polymer technology, which is applied in the field of proton exchange membrane and preparation of tadpole-type sulfonated POSS-containing hybrid polymer synthesis, can solve the problems of lower water content and lower proton conductivity, and improve the proton conductivity. , good hydrophilicity, excellent thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

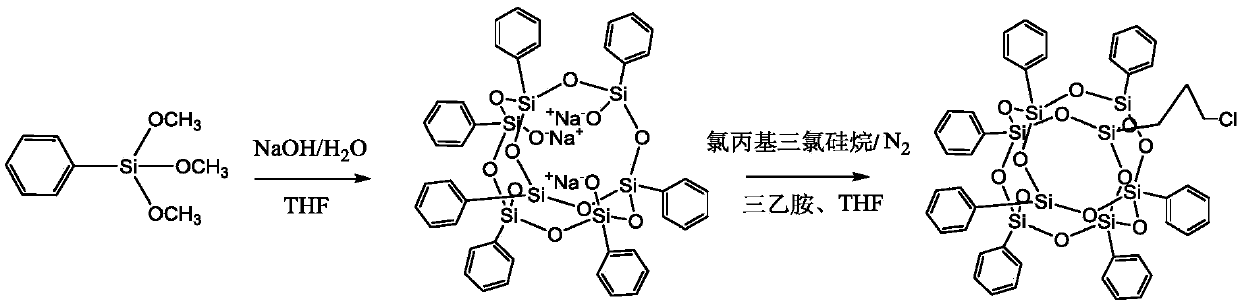

[0030] A method for preparing the tadpole-shaped organic-inorganic hybrid topological polymer with silsesquioxane as the core and methyl methacrylate block polystyrene as the arm and the preparation method of the proton exchange membrane thereof, characterized The steps are as follows:

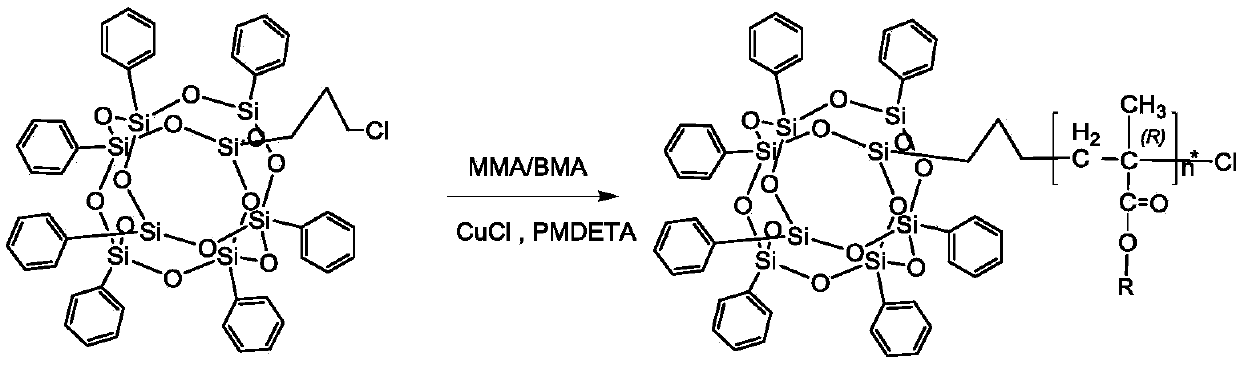

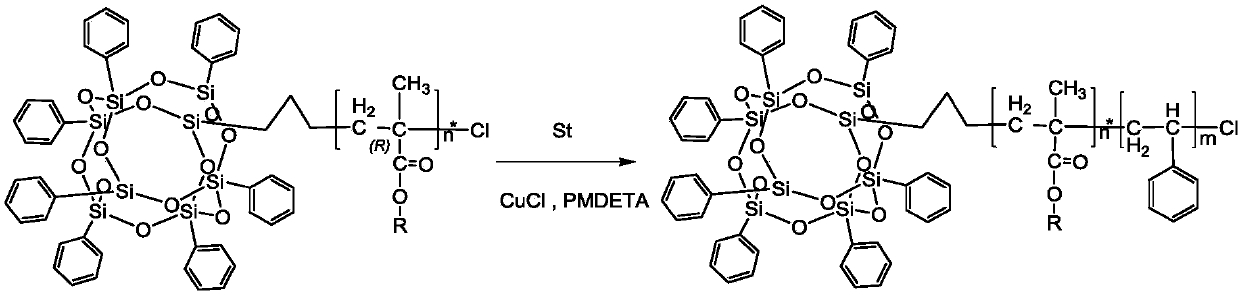

[0031]Step 1: Mix a certain proportion of monochloropropyl silsesquioxane, pentamethyldivinyltriamine (PMDETA), cuprous chloride (CuCl), methyl methacrylate monomer (MMA) In a three-neck flask, add toluene as a solvent, freeze—vacuumize—pass nitrogen three times to remove the air, then stir under the protection of nitrogen, and react at 100°C~110°C for 12h~24h; after the reaction, use the obtained product Tetrahydrofuran was dissolved to obtain a polymer solution; the polymer solution was passed through a neutral alumina column to remove the catalyst, concentrated and precipitated with anhydrous methanol, and dried in a vacuum oven at 50°C to constant weight to obtain a white solid POSS-PMMA-C...

Embodiment 1

[0036] Step 1: Add 45g of phenyltrimethoxysilane (0.23mol), 250mL of tetrahydrofuran (THF), 5.25g of deionized water (0.29mol) and 4.0g of sodium hydroxide (0.2mol) into a tube equipped with a condenser and a magnetic in a three-necked flask with a stirrer. The reaction mixture was refluxed at 70°C for 5 hours, then cooled to room temperature, and the reaction was continued for 15 hours. After the reaction, the solvent was removed by a rotary evaporator to obtain a white primary product. The initial product was dissolved in tetrahydrofuran and filtered three times to remove insoluble components. After concentration, a white solid was obtained, which was dried under vacuum at 50°C for 24 hours to obtain POSS. Add POSS (10.0g, 8.8mmol), triethylamine (1.3mL, 8.8mmol), and 200mL anhydrous tetrahydrofuran into a three-necked flask respectively, and stir for 1 hour in an ice-water bath with nitrogen gas; Chloropropyltrichlorosilane (2.24 g, 0.56 mmol) in 20 mL of anhydrous THF w...

Embodiment 2

[0042] Step 1: Add 45g of phenyltrimethoxysilane (0.23mol), 250mL of tetrahydrofuran (THF), 5.25g of deionized water (0.29mol) and 4.0g of sodium hydroxide (0.2mol) into a tube equipped with a condenser and a magnetic in a three-necked flask with a stirrer. The reaction mixture was refluxed at 70°C for 5 hours, then cooled to room temperature, and the reaction was continued for 15 hours. After the reaction, the solvent was removed by a rotary evaporator to obtain a white primary product. The initial product was dissolved in tetrahydrofuran and filtered three times to remove insoluble components. After concentration, a white solid was obtained, which was dried under vacuum at 50°C for 24 hours to obtain POSS. Add POSS (10.0g, 8.8mmol), triethylamine (1.3mL, 8.8mmol), and 200mL anhydrous tetrahydrofuran into a three-necked flask respectively, and stir for 1 hour in an ice-water bath with nitrogen gas; Chloropropyltrichlorosilane (2.24 g, 0.56 mmol) in 20 mL of anhydrous THF w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com