Method for loading titania microflowers on shaped carbon material

A technology of titanium dioxide and carbon materials, applied to the surface loading of carbon materials, in the field of loading titanium dioxide micron flowers on the surface of formed carbon materials, it can solve the problems of hydrothermal reaction liquid adsorption residue, uneven titanium dioxide film, difficult to control thickness, etc., to reduce solid The effect of liquid interfacial tension, easy recycling and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

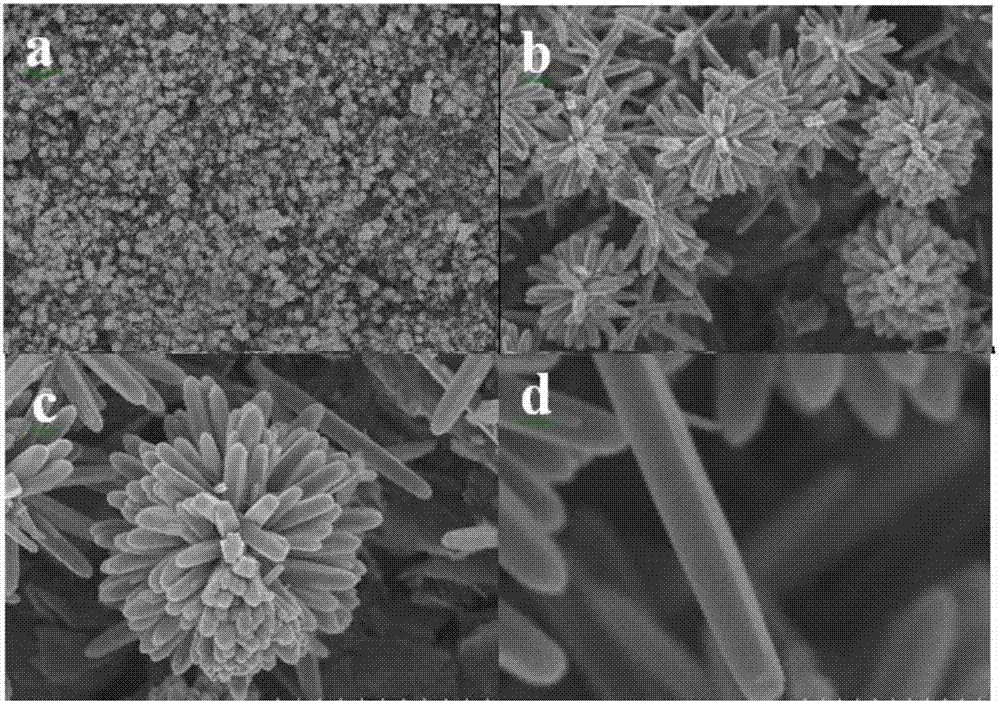

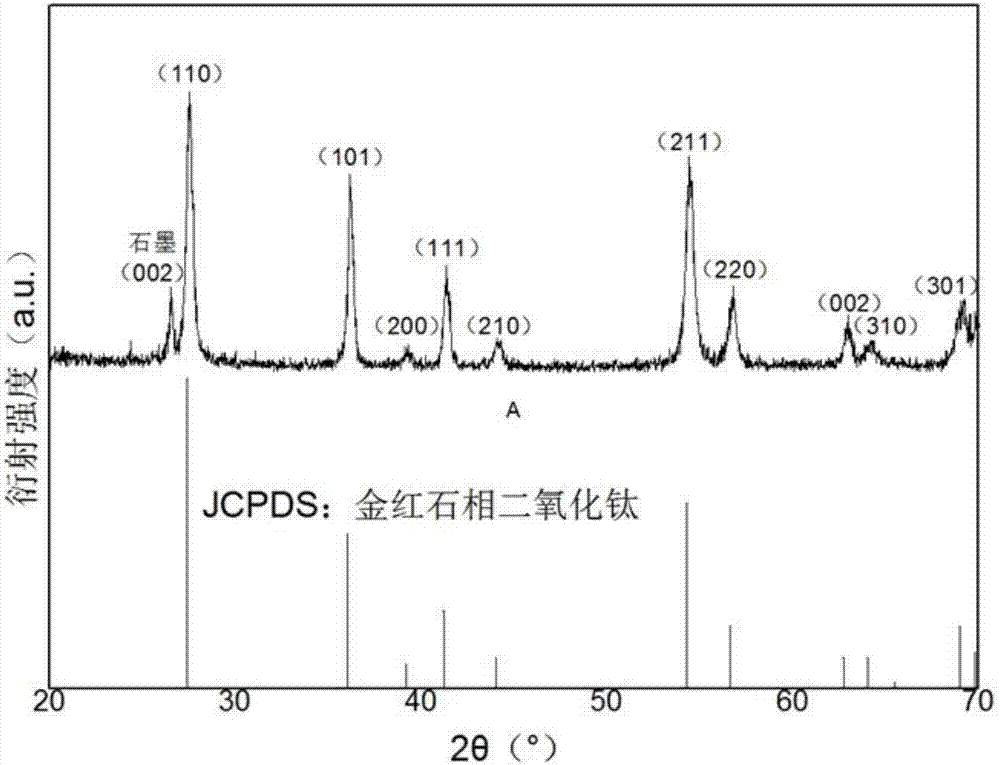

[0032] Preparation of titanium dioxide micro-flower electrode supported on graphite plate:

[0033] The high-temperature pyrolytic graphite plate was polished to smooth with P400 sandpaper, P1500 sandpaper and 0.05 μm aluminum powder in sequence, and then ultrasonicated in acetone, ethanol, and deionized water for 10 minutes, and dried for later use. Slowly pour 20mL of deionized water into 10mL of ethanol and stir for 5min; slowly pour the mixed solution of ethanol and water into 30mL of concentrated hydrochloric acid and stir for 5min; add 1mL of tetrabutyl titanate dropwise into ethanol, water and concentrated hydrochloric acid Mix the solution while vigorously stirring until the solution is clear to obtain a hydrothermal reaction solution. Lean the cleaned graphite plate against the wall of a 100mL hydrothermal kettle at 45°, pour 60mL of the prepared hydrothermal reaction solution to immerse the graphite plate, and ultrasonicate for 20min. Seal the hydrothermal kettle, k...

specific Embodiment 2

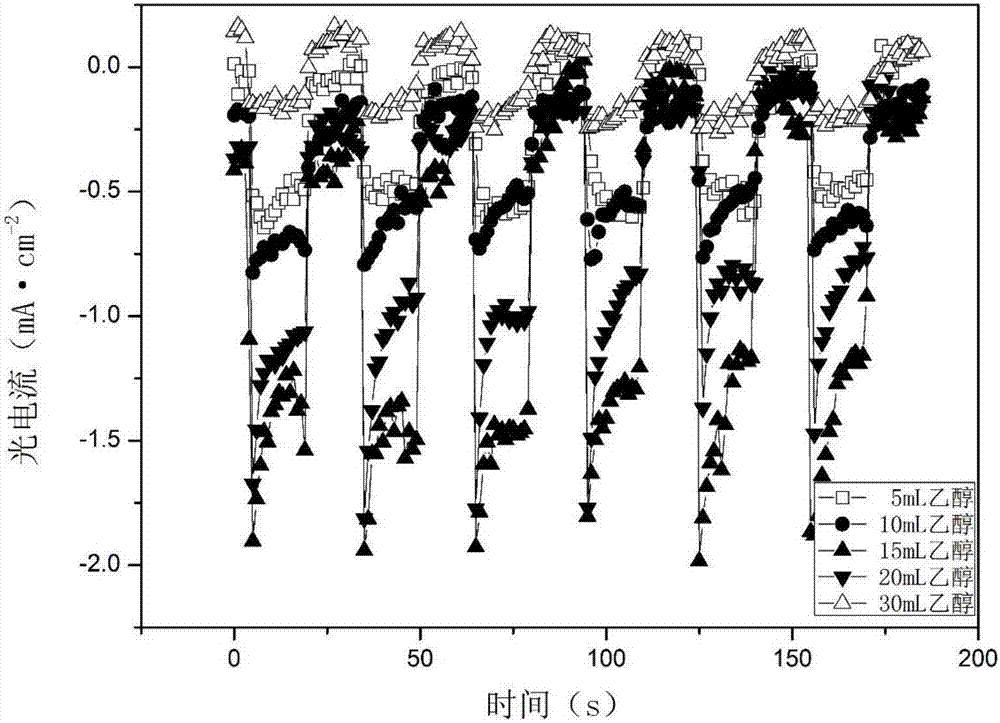

[0035] Preparation of ink plate-supported titanium dioxide micro-flower electrodes using hydrothermal reaction solutions configured with different ethanol ratios:

[0036] The high-temperature pyrolytic graphite plate was polished to smooth with P400 sandpaper, P1500 sandpaper and 0.05 μm aluminum powder in sequence, and then ultrasonicated in acetone, ethanol, and deionized water for 10 minutes, and dried for later use. Slowly add 5, 10, 15, 20, 30 mL of ethanol into 25, 20, 15, 10, 0 mL of deionized water, respectively, and stir for 5 min to obtain mixed solutions (or monomers) of ethanol and water in different proportions. Slowly pour the mixed solution (or monomer) of ethanol and water into 30mL of concentrated hydrochloric acid and stir for 5min; add 1mL of tetrabutyl titanate dropwise into the mixed solution while vigorously stirring until the solution is clear to obtain a hydrothermal reaction solution . Lean the cleaned graphite plate against the wall of a 100mL hydro...

specific Embodiment 3

[0038] The preparation method of the titanium dioxide nanoflower-coated carbon material of this embodiment is the same as that of the specific example 1, and the specific parameters are: the graphite rod is used as the base material, and after being ultrasonicated in acetone, ethanol, and deionized water for 10 minutes, place it at an angle of 30° In a 100mL hydrothermal kettle, pour a mixed solution of 30mL concentrated hydrochloric acid, 10mL deionized water, 20mL ethanol and 2mL tetrabutyl titanate to immerse the graphite rod, ultrasonicate for 20min, seal the hydrothermal kettle, and keep it warm at 140°C for 2h , cooled to room temperature, took out the sample, rinsed it four times with deionized water, soaked it in deionized water at room temperature for 20 minutes, and then dried it at 120°C for 2 hours in the dark, and kept the dried sample at 550°C for 0.5 h, cooling down to room temperature, the titanium dioxide micron flower-coated graphite rod is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com