Method for producing bacteriostatic isomaltooligosaccharide by using broken rice

A technology of isomaltooligosaccharide and broken rice, which is applied in the direction of preserving fruits/vegetables with sugar, food science, fermentation, etc., to achieve the effects of pathogenic bacteria inhibition, high extraction rate, and reduced material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

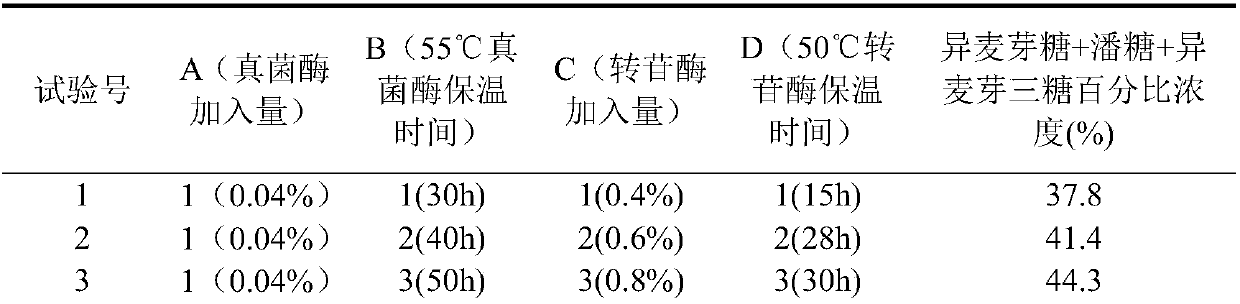

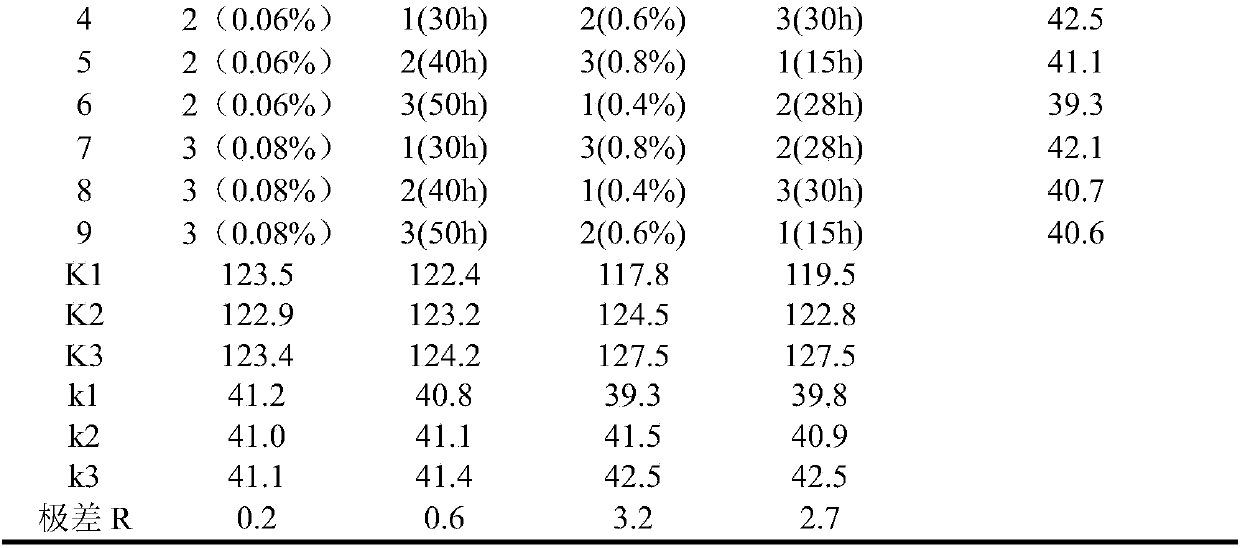

Image

Examples

Embodiment 1

[0036] 1.1 Broken rice grinding and protein removal

[0037] After the broken rice is dried, pass it through a 100-mesh sieve to obtain the raw material dry powder; add deionized water to prepare a solid-liquid ratio of 1:20, stir evenly, and obtain a rice flour suspension;

[0038] Immerse the ultrasonic probe into the rice flour suspension at a distance of 30% from the height of the liquid surface, place the ultrasonic probe coaxially with the container containing the rice flour suspension, and in the middle of the liquid surface, and conduct the process in an ice-water bath with an ultrasonic power of 650W. Ultrasonic treatment, the ultrasonic time is 30min, and the ultrasonic treatment is carried out in the intermittent mode of alternating 1s ultrasonic and 1s intermittent;

[0039] Centrifuge, extract the supernatant, concentrate with a rotary evaporator, add 5 times the volume of absolute ethanol, carry out alcohol precipitation, leave it for 12 hours and then centrifuge...

Embodiment 2

[0053] 2.1 Broken rice grinding and protein removal

[0054] After the broken rice is dried, pass through a 40-mesh sieve to obtain the raw material dry powder; add deionized water to prepare a solid-liquid ratio of 1:6, stir evenly, and obtain a rice flour suspension;

[0055] Immerse the ultrasonic probe into the rice flour suspension at a distance of 30% from the height of the liquid surface. Place the ultrasonic probe coaxially with the container containing the rice flour suspension and in the middle of the liquid surface. In an ice-water bath, the ultrasonic power is 450W. Ultrasonic treatment, the ultrasonic time is 15min, and the ultrasonic treatment is carried out in the intermittent mode of alternating 1s ultrasonic and 1s intermittent;

[0056] Centrifuge, extract the supernatant, concentrate with a rotary evaporator, add 2 times the volume of absolute ethanol, carry out alcohol precipitation, leave it for 8 hours and then centrifuge again, take the precipitate, dry ...

Embodiment 3

[0070] 3.1 Broken rice grinding and protein removal

[0071] After the broken rice is dried, pass through a 40-mesh sieve to obtain the raw material dry powder; add deionized water to prepare a solid-liquid ratio of 1:15, stir evenly, and obtain a rice flour suspension;

[0072] Immerse the ultrasonic probe into the rice flour suspension at a distance of 20% from the height of the liquid surface. Place the ultrasonic probe coaxially with the container containing the rice flour suspension and in the middle of the liquid surface. ℃, ultrasonic treatment was carried out at an ultrasonic power of 600W, and the ultrasonic time was 30min.

[0073] Centrifuge, extract the supernatant, concentrate with a rotary evaporator, add 3 times the volume of absolute ethanol, carry out alcohol precipitation, leave it for 12 hours and then centrifuge again, take the precipitate, dry to constant weight, and weigh the weight of rice flour;

[0074] 3.2 Sizing and starch liquefaction

[0075] Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com