Sodium salt added roasting method of metal in recycled waste lithium battery cathode powder

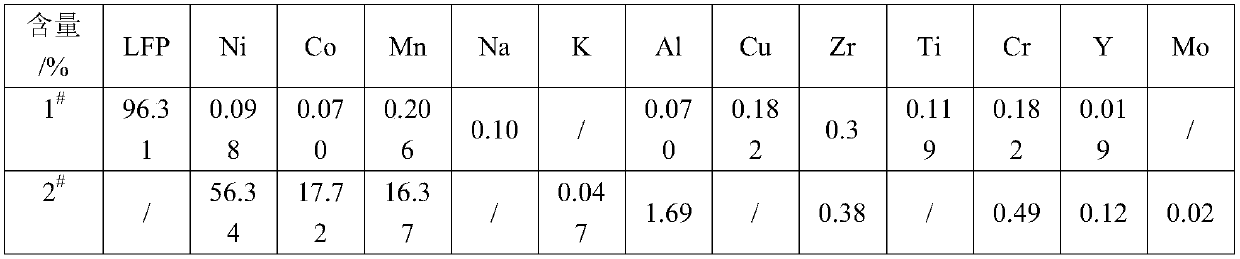

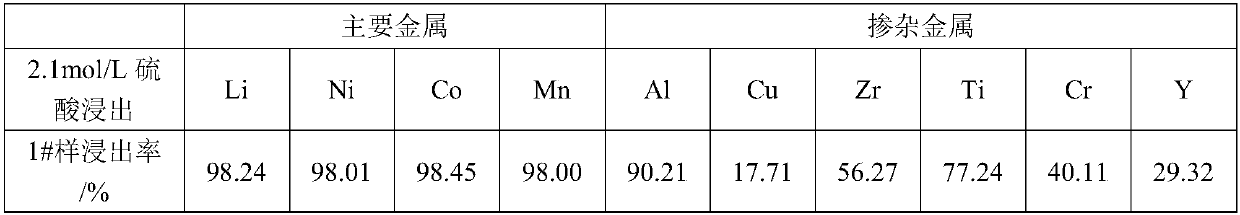

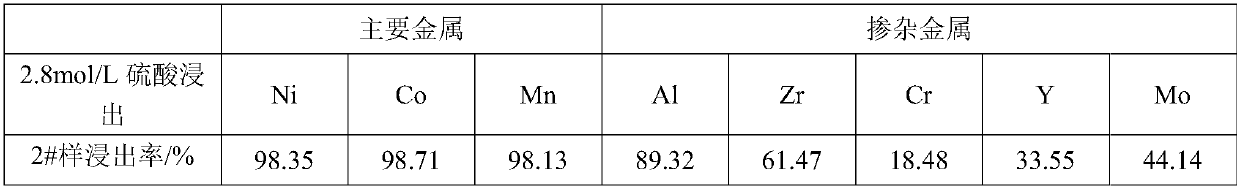

A waste lithium battery and positive electrode technology, which is applied in the field of sodium salt roasting of metals in the positive electrode powder of recycled waste lithium batteries, can solve the problems of low doping metal content, poor recovery value, low leaching rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A sodium salt roasting method for recycling metals in the positive electrode powder of waste lithium batteries, comprising the steps of:

[0023] S1. Add waste lithium battery positive electrode powder and sodium salt mixture to the mixer to obtain the mixture;

[0024] S2. Send the mixed material obtained in S1 into the ball of the hydraulic pressure ball mechanism to obtain the material ball;

[0025] S3. Roasting, crushing, grinding, and acid leaching the material balls obtained in S2 to obtain an acid leaching solution.

Embodiment 2

[0027] A sodium salt roasting method for recycling metals in the positive electrode powder of waste lithium batteries, comprising the steps of:

[0028] S1. Add waste lithium battery positive electrode powder and NaCl mixture to the mixer; the weight ratio of waste lithium battery positive electrode powder to sodium chloride is 1:0.1, the rotation speed of the mixer is 100r / min, and the revolution speed 5r / min, mixing time is 0.5h;

[0029] S2. Send the mixed material obtained in S1 into a hydraulic pressure ball machine ball to obtain a material ball; wherein the ball making pressure is 0.4MPa, and the material ball radius R=10mm;

[0030] S3. Roast the material balls obtained in S2. The roasting temperature is 850°C, the roasting time is 2h, then crushed, ground, and pickled with hydrochloric acid. The concentration of hydrochloric acid is 0.3mol / L, the solid-to-liquid ratio is 1:2, and the leaching time is 1h, the leaching temperature is 80°C, and the acid leaching solutio...

Embodiment 3

[0032] A sodium salt roasting method for recycling metals in the positive electrode powder of waste lithium batteries, comprising the steps of:

[0033] S1. Add waste lithium battery positive electrode powder and NaCl mixture to the mixer; the weight ratio of waste lithium battery positive electrode powder to sodium chloride is 1:0.2, the rotation speed of the mixer is 80r / min, and the revolution speed 1r / min, mixing time is 2h;

[0034] S2. Send the mixed material obtained in S1 into the ball of the hydraulic pressure ball mechanism to obtain the material ball; wherein the ball making pressure is 0.2MPa, and the material ball radius R=30mm;

[0035] S3. Roast the material balls obtained in S2. The roasting temperature is 650°C, the roasting time is 4h, then crushed, ground, and pickled with hydrochloric acid. The concentration of hydrochloric acid is 0.1mol / L, the solid-to-liquid ratio is 1:4, and the leaching time is 2h, the leaching temperature is 60°C, and the acid leachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com