A kind of cr/crnx heat-insulating film used on the top surface of aluminum alloy piston and its preparation method

A technology of aluminum alloy and piston top, which is applied in the direction of pistons, mechanical equipment, machines/engines, etc., can solve problems such as lack of application, achieve the effects of reducing stress, high ionization rate, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

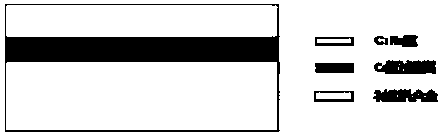

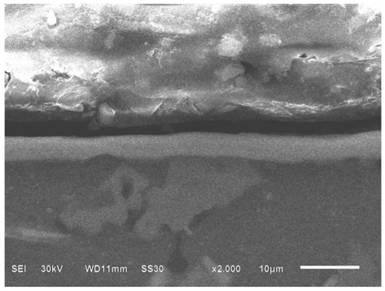

[0049] The invention provides a chromium nitride film on the top surface of an aluminum alloy piston and a preparation method thereof. In order to achieve the purpose of the invention, the technical solution of the invention mainly includes two steps: one is a pretreatment process; the other is a preparation process. The pretreatment process is exactly the same, but the preparation process is different. The pretreatment process mainly includes:

[0050] (1) Use 400#, 800#, 1000#, 1200#, 2000# sandpaper to grind and polish the base of the aluminum alloy piston successively, and then take appropriate amount of acetone solution and absolute ethanol solution to polish the base respectively. Ultrasonic cleaning for 10-15 minutes;

[0051] (2) Before putting the sample into the magnetic filtration cathode vacuum chamber equipment, use a vacuum cleaner to suck the residual dust and attachments in the magnetic filtration cathode arc vacuum chamber, and wipe the sample stage with abso...

Embodiment 1

[0054] Embodiment one (ventilation volume 5sccm, time 120min):

[0055] A kind of Cr / CrN used on the top surface of aluminum alloy piston X A similar heat-insulating film and a preparation method thereof are realized through the following steps:

[0056] (1) Put in the sample, turn on the magnetic filter titanium power supply arc, use the pure metal Cr target as the cathode, adjust the arcing current 100A, negative bias voltage -50v, curved tube magnetic field 1.5A, straight tube magnetic field 3.5A, duty cycle 90% , deposit a pure metal Cr film layer on the pretreated substrate surface, and the deposition time is 20min.

[0057] (2) Turn on the magnetic filter titanium power supply arc, adjust the duty ratio to 20%, and open the gas flow switch to feed the reaction gas nitrogen at the same time, the ventilation rate is 5sccm, and the deposition time is 100min to obtain Cr / CrN X film layer.

[0058] (3) Turn off the gas flow switch, turn off the switch, turn off the arc sou...

Embodiment 2

[0060] Embodiment two (ventilation volume 10sccm, time 120min):

[0061] A kind of Cr / CrN used on the top surface of aluminum alloy piston X A similar heat-insulating film and a preparation method thereof are realized through the following steps:

[0062] (1) Put in the sample, turn on the magnetic filter titanium power supply arc, use the pure metal Cr target as the cathode, adjust the arcing current 100A, negative bias voltage -50v, curved tube magnetic field 1.5A, straight tube magnetic field 3.5A, duty cycle 90% , deposit a pure metal Cr film layer on the pretreated substrate surface, and the deposition time is 20min.

[0063] (2) Turn on the magnetic filter titanium power supply arc, adjust the duty ratio to 20%, and open the gas flow switch to feed the reaction gas nitrogen at the same time, the ventilation rate is 10sccm, and the deposition time is 100min to obtain Cr / CrN X film layer.

[0064] (3) Turn off the gas flow switch, turn off the switch, turn off the arc s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com