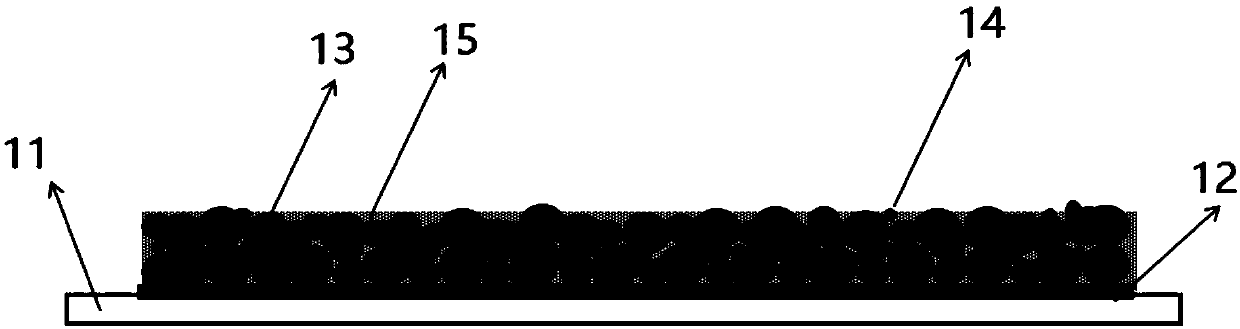

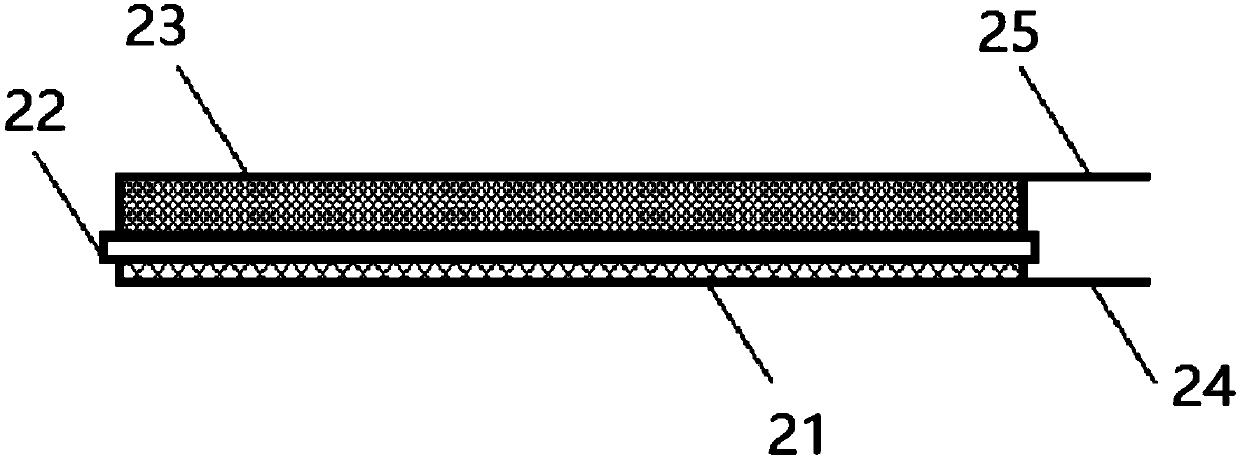

Gel composite positive pole plate, preparation method thereof and method for preparing all-solid-state lithium battery

A technology of composite positive electrode and positive electrode sheet, which is applied in the direction of lithium battery, electrode manufacturing, battery electrode, etc., can solve the problems of positive electrode sheet and solid electrolyte interface impedance, etc., achieve high active material content, improve interface impedance, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

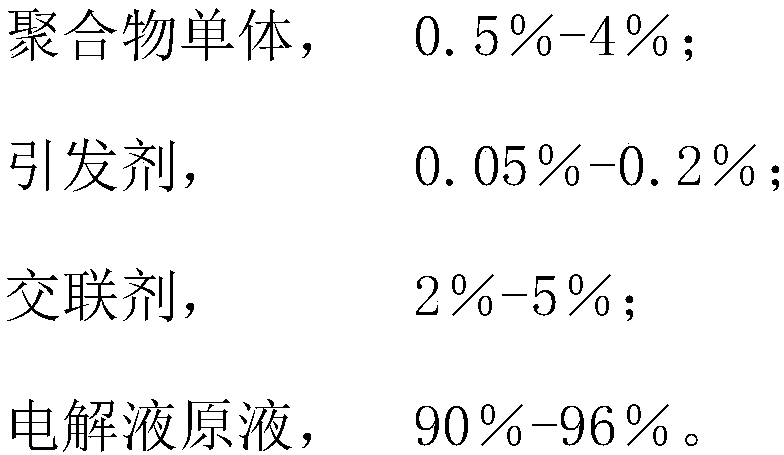

[0055] Prepare the gel electrolyte: obtain 1.5% polymer monomer by mass percentage; 0.1% initiator; 2.5% cross-linking agent; and the balance of electrolyte stock solution. In this embodiment, the polymer monomer is methyl methacrylate, the initiator is azobisisobutyronitrile; the crosslinking agent is polyethylene glycol acrylate, and the electrolyte stock solution is lithium The carbonate organic matter solution of the salt, specifically lithium hexafluorophosphate solution, has a concentration of 0.8 mol / L. Add the methyl methacrylate, azobisisobutyronitrile and polyethylene glycol acrylate into the lithium hexafluorophosphate, mix and dissolve thoroughly to obtain a gel electrolyte.

[0056] Step S1) prepare slurry:

[0057] The raw materials of the slurry are obtained by mass percentage: 4% of the binder, 4% of the conductive agent and the remaining active material of the positive electrode. The binder is polyvinylidene fluoride, the conductive agent is carbon nanotube,...

Embodiment 2

[0067] Prepare the gel electrolyte: obtain 2.5% polymer monomer by mass percentage; 0.1% initiator; 5% cross-linking agent; and the balance of electrolyte stock solution. In this embodiment, the polymer monomer is butyl acrylate, the initiator is azobisisobutyronitrile; the crosslinking agent is polyethylene glycol acrylate, and the electrolyte stock solution is lithium salt The organic carbonate solution, specifically lithium perchlorate solution, has a concentration of 0.8 mol / L. Add the butyl acrylate, azobisisobutyronitrile and polyethylene glycol acrylate into the lithium perchlorate, mix and dissolve thoroughly to obtain a gel electrolyte.

[0068] Step S1) prepare slurry:

[0069] The raw materials of the slurry are obtained by mass percentage: 8% of binder, 4% of conductive agent and the remaining positive electrode active material. The binder is polyvinylidene fluoride, the conductive agent is conductive carbon black, and the positive electrode active material is li...

Embodiment 3

[0079] Prepare the gel electrolyte: obtain 4% of the polymer monomer by mass percentage; 0.2% of the initiator; 5% of the cross-linking agent; and the balance of the electrolyte stock solution. In this embodiment, the polymer monomer is triethylene glycol diacrylate, the initiator is azobisisobutyronitrile; the polyethylene glycol methyl acrylate; the electrolyte stock solution is lithium salt Carbonate organic matter solution, specifically lithium perchlorate solution, its concentration is 1.0mol / L. Add the triethylene glycol diacrylate, azobisisobutyronitrile and polyethylene glycol methyl acrylate into the lithium perchlorate, mix and dissolve to obtain a gel electrolyte.

[0080] Step S1) prepare slurry:

[0081] The raw materials of the slurry are obtained by mass percentage: 8% of binder, 8% of conductive agent and the remaining positive electrode active material. The binder is polyvinylidene fluoride, the conductive agent is conductive carbon black, and the positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com