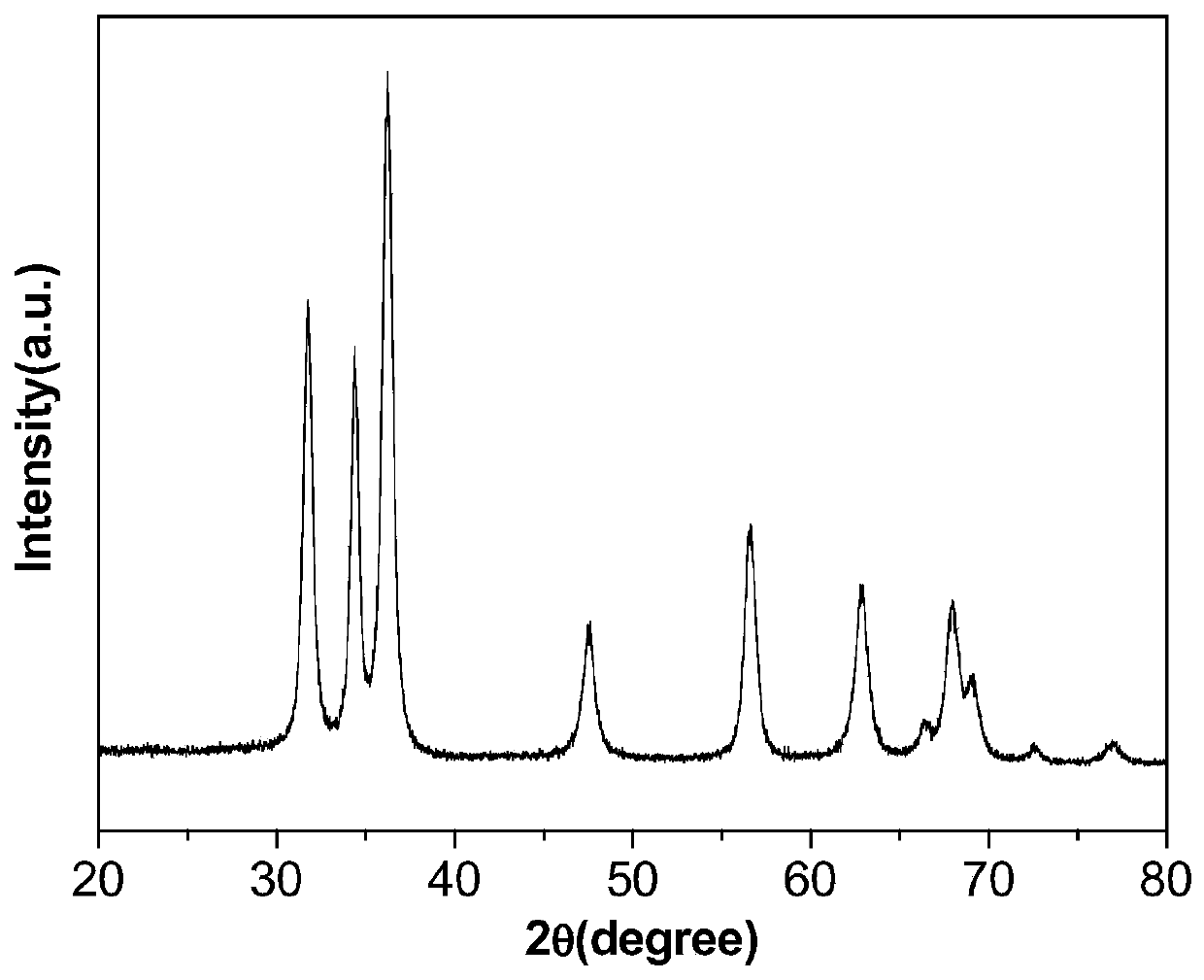

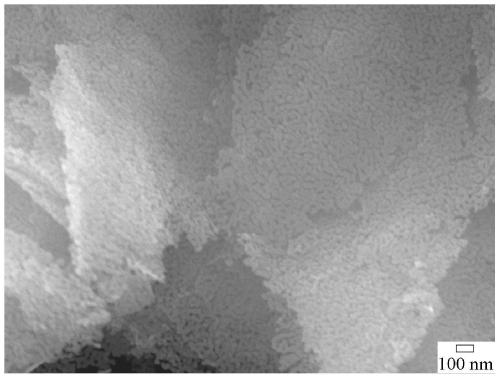

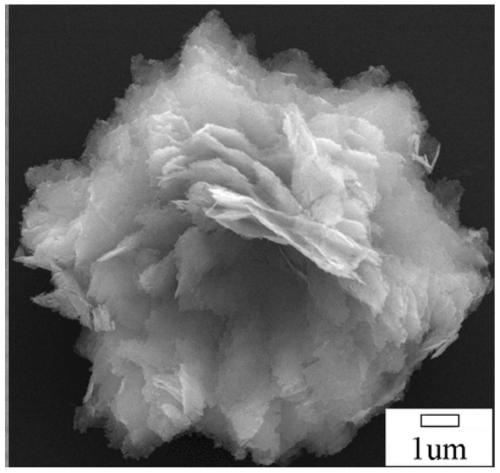

A nanoparticle self-assembled peony-like la 3+ Doping zno and its preparation method and application

A nanoparticle and self-assembly technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve the problems of difficult rare earth ion doping, large radius gap, inconsistent valence, etc., and achieve simple equipment and exposed area. Large, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 1.7849g Zn(NO 3 ) 2 ·6H 2 O and 3.6036g urea were dissolved in 60ml deionized water respectively, stirred at room temperature for 5min respectively, then the urea solution after the stirring was added to Zn(NO 3 ) 2 The solution was stirred at room temperature for 5 min.

[0027] 2) The stirred Zn(NO 3 ) 2The solution was placed in a 92°C drying oven to react for 7 hours. After cooling at room temperature, the precipitate was collected by centrifugation, and then alternately centrifuged with ethanol and deionized water for 2-3 times (centrifugal speed 12000rpm, 3min). The washed sample was placed under the condition of 60°C Dry for 30-40 minutes, collect the precursor after grinding. The precursor was taken out and ground, and then placed in a tube furnace at 400°C and annealed for 2 hours in an air atmosphere to obtain the final product.

Embodiment 2

[0029] 1) Weigh 1.7760g Zn(NO 3 ) 2 ·6H 2 O, 0.0130g La(NO 3 ) 3 ·6H 2 O and 3.6036g urea, the Zn(NO 3 ) 2 ·6H 2 O and La(NO 3 ) 3 ·6H 2 After mixing O, dissolve in 60ml deionized water and stir at room temperature for 5 minutes, take another 60ml of deionized water, dissolve urea in water and stir for 5 minutes at room temperature, then add the stirred urea solution into the mixed solution of Zn and La, and continue stirring at room temperature for 5 minutes.

[0030] 2) Put the stirred mixed solution in a 92°C drying oven to react for 7 hours, and centrifuge to collect the precipitate after cooling at room temperature, then alternately centrifuge and wash with ethanol and deionized water for 2-3 times (centrifugal speed 12000rpm, 3min), wash the The samples were dried at 60°C for 30-40 minutes, and the precursors were collected after grinding. The precursor was taken out and ground, and then placed in a tube furnace at 400°C and annealed for 2 hours in an air atmo...

Embodiment 3

[0032] 1) Weigh 1.7671g Zn(NO 3 ) 2 ·6H 2 O, 0.0260g La(NO 3 ) 3 ·6H 2 O and 3.6036g urea, the Zn(NO 3 ) 2 ·6H 2 O and La(NO 3 ) 3 ·6H 2 After mixing O, dissolve in 60ml deionized water and stir at room temperature for 5 minutes, take another 60ml of deionized water, dissolve urea in water and stir for 5 minutes at room temperature, then add the stirred urea solution into the mixed solution of Zn and La, and continue stirring at room temperature for 5 minutes.

[0033] 2) Put the stirred mixed solution in a 92°C drying oven to react for 7 hours, and centrifuge to collect the precipitate after cooling at room temperature, then alternately centrifuge and wash with ethanol and deionized water for 2-3 times (centrifugal speed 12000rpm, 3min), wash the The samples were dried at 60°C for 30-40 minutes, and the precursors were collected after grinding. The precursor was taken out and ground, and then placed in a tube furnace at 400°C and annealed for 2 hours in an air atmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com