A low-temperature liquid-phase growth method for preparing zno nanocone arrays

A low-temperature liquid phase, growth method technology, applied in liquid phase epitaxy layer growth, single crystal growth, crystal growth and other directions, can solve the problem of low quality of ZnO nanostructure array, affecting ZnO crystal grain crystallization and growth, ZnO quality and purity It can achieve the effect of low cost, high crystal quality and purity, and improving the quality and purity of ZnO.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

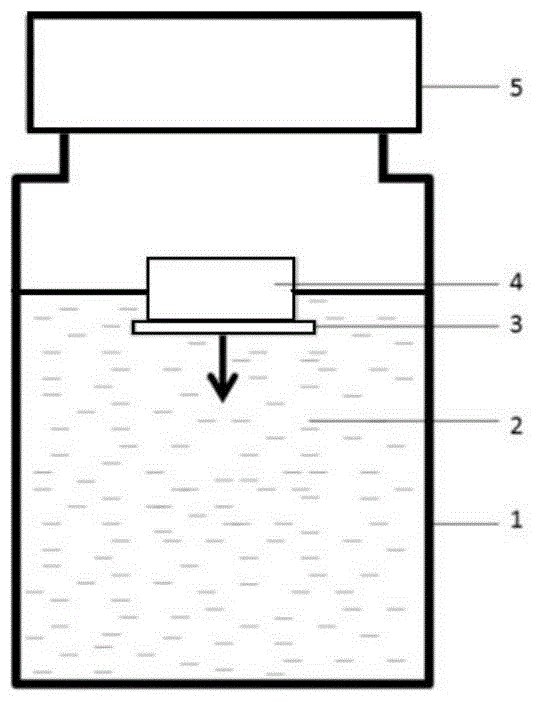

[0033] Embodiment 1 Cu substrate grows ZnO nanocone array at 35°C

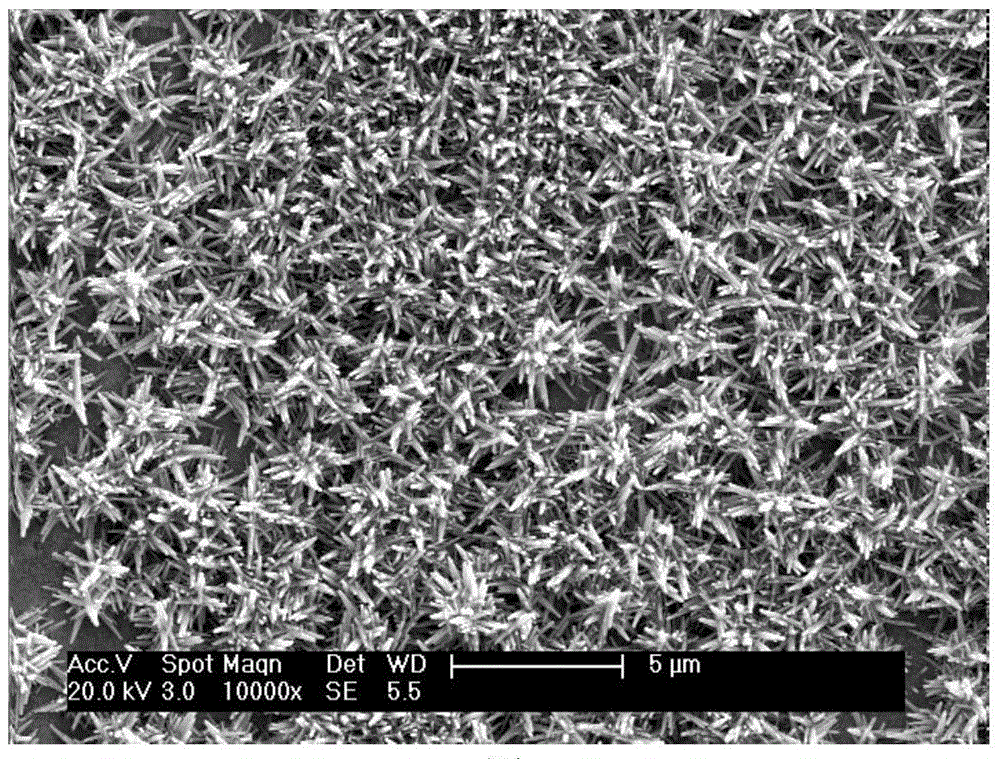

[0034] ①Respectively prepare a concentration of 4.0mol L -1 KOH aqueous solution and a concentration of 0.5mol L -1 Zn(NO 3 ) 2 aqueous solution. ②KOH aqueous solution and Zn(NO 3 ) 2 The aqueous solution is mixed according to the volume ratio of 1:1, and at the same time, it is fully magnetically stirred. After the reaction, a clear solution is obtained, which is the required 0.25mol L -1 Zn(OH) 4 2- reaction solution. ③ Pour the reaction solution into the reaction container, and then suspend the cleaned Cu substrate growth side down in the reaction solution (such as figure 1 ), then seal the reaction vessel, place it in an electrothermal constant temperature water tank that has reached the reaction temperature, grow in a water bath at 35°C for 1h, 4h, and 12h, take it out, rinse it with deionized water, and then rinse it with absolute ethanol. After vacuum drying at room temperature, it can be foun...

Embodiment 2

[0037] Embodiment 2: grow ZnO nanocone array on FTO glass substrate

[0038] Using the substrate placement method described in this patent, by KOH and Zn(NO 3 ) 2 Prepared 0.25mol·L -1 Zn(OH) 4 2- In the reaction system, using FTO glass as the substrate, the ZnO array thin film prepared after 12h growth in 35℃ water bath, the morphology is as follows: Figure 8 shown.

Embodiment 3

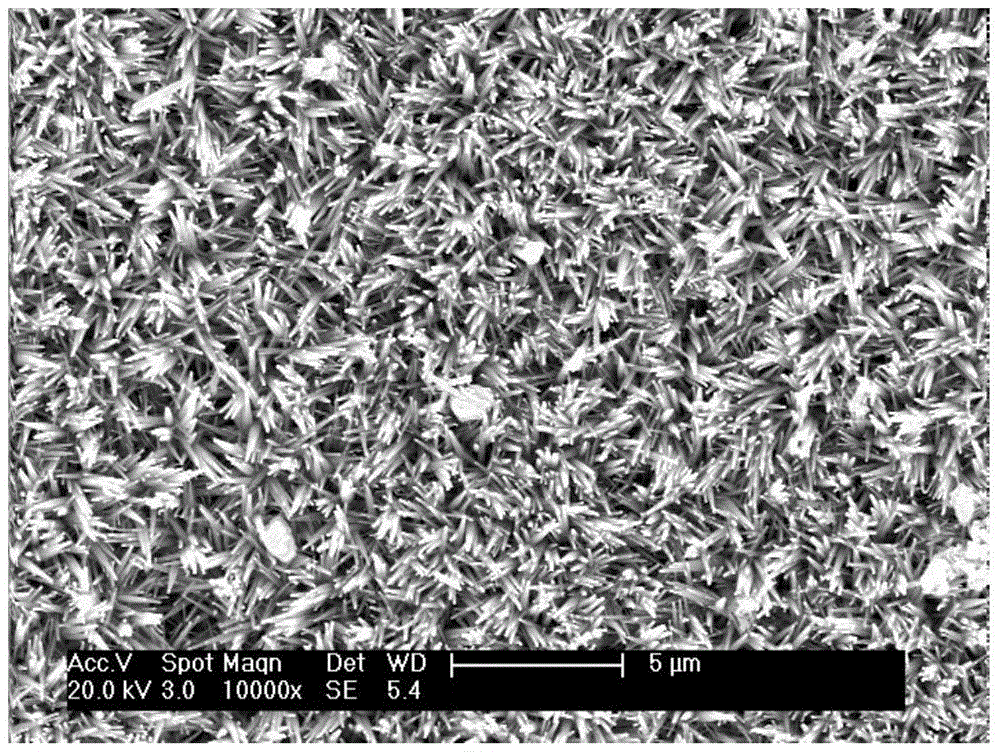

[0039] Embodiment 3: Cu substrate grows ZnO nano cone array at different temperatures

[0040] Adopt the substrate placing method described in the present invention, in by KOH and Zn(NO 3 ) 2 Prepared 0.25mol·L -1 Zn(OH) 4 2- In the reaction system, the prepared and cleaned Cu sheet was used as the substrate, and the ZnO array films were grown in water baths at 25°C and 40°C for 12 hours, and the morphology was as follows: Figure 9 and Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com