Silicon-aluminum-phosphate molecular sieve and synthesis method thereof

A technology of silicoaluminophosphate and synthesis method, which is applied in the field of catalysis, can solve the problems of long molecular sieve paths, and achieve the effects of short diffusion paths, not easy to block pores, and prolonged catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

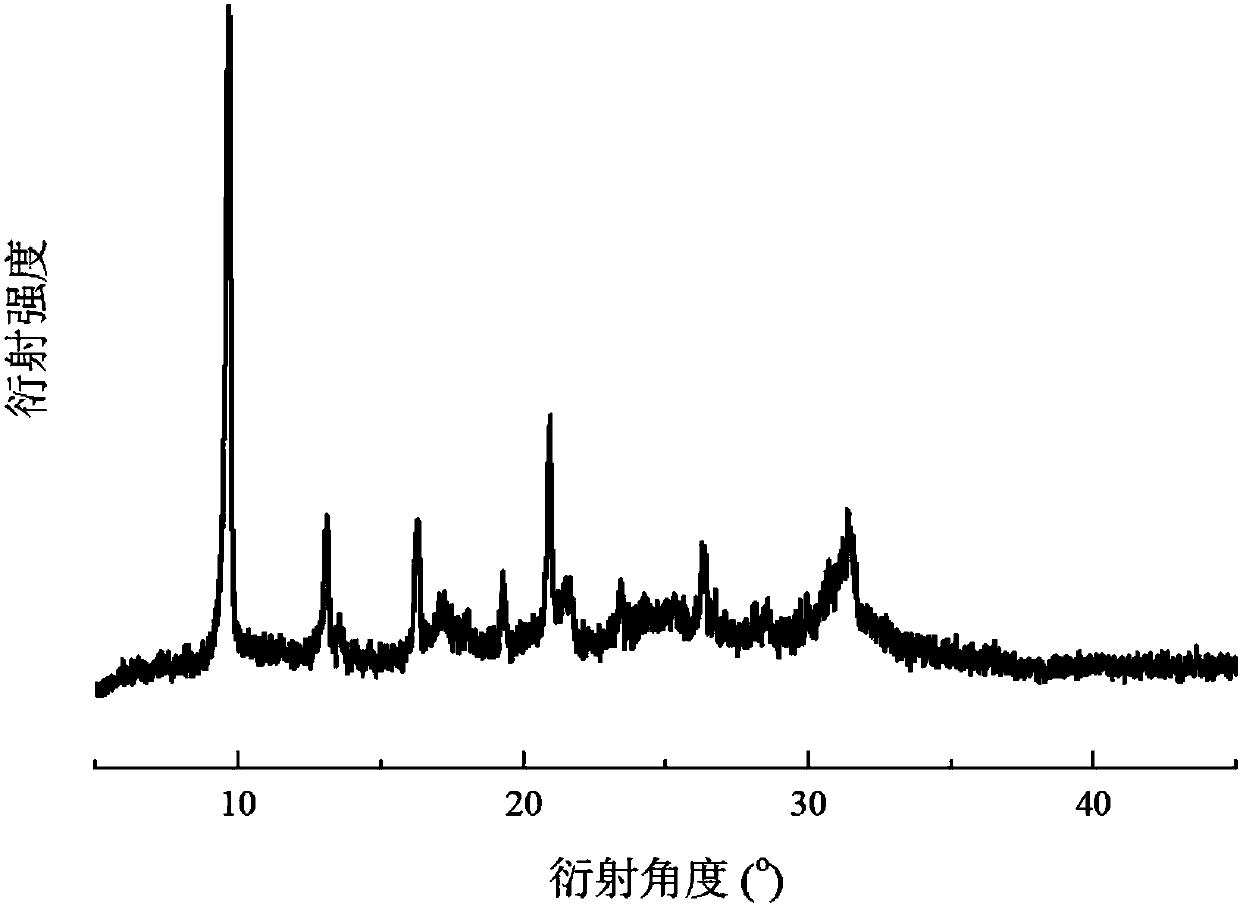

Image

Examples

Embodiment 1

[0030] Molecular sieves were synthesized as follows:

[0031] (1) The phosphorus source, the silicon source, the aluminum source, the templating agent and water are mixed according to the molar ratio of Si:P:Al:template:water of 0.1:1:1:2:50, and the mixing sequence is to mix the aluminum source with The silicon source is mixed, then the phosphorus source is added, and finally the template is added to control the mixing rate, wherein the phosphorus source is phosphoric acid, the silicon source is silica sol, the aluminum source is pseudoboehmite, and the template is triethylamine;

[0032] (2) stirring the mixture obtained in step (1), stirring at 60° C. for 6 hours;

[0033] (3) The mixture obtained in step (2) was placed in a reactor for hydrothermal crystallization for 36 hours, and the crystallization temperature was kept at 200°C;

[0034] (4) Centrifuge the mixture obtained in step (3) at a speed of 5000 rpm for 10 minutes, wash until the pH of the filtrate is less than...

Embodiment 2

[0039] Molecular sieves were synthesized as follows:

[0040] (1) The phosphorus source, the silicon source, the aluminum source, the templating agent and water are mixed according to Si:P:Al:template agent:water molar ratio is 0.05:1:1:1.5:20, and the mixing sequence is to mix the aluminum source with Mix the silicon source, then add the phosphorus source, and finally add the template agent to control the mixing rate, wherein the phosphorus source is ammonium dihydrogen phosphate, the silicon source is water glass, the aluminum source is pseudoboehmite, and the template agent is tetraethylhydrogen A mixture of ammonium oxide and polyethylene glycol;

[0041] (2) stirring the mixture obtained in step (1), stirring at 80° C. for 2 hours;

[0042] (3) The mixture obtained in step (2) was placed in a reactor for hydrothermal crystallization for 40 hours, and the crystallization temperature was kept at 190°C;

[0043] (4) Centrifuge the mixture obtained in step (3) at a speed of...

Embodiment 3

[0050] The molecular sieves synthesized in Example 1, Example 2 and Comparative Example 1 were characterized by the nitrogen adsorption method, and the micropore and mesopore specific surface area of the molecular sieve were calculated by the NLDFT method. The results obtained are shown in Table 1, as can be seen, Compared with Comparative Example 1, the micropores of Example 1 and Example 2 are closer, but the mesopore content is more abundant.

[0051] Table 1 Micropore and mesopore distribution of molecular sieves

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com