Biogas residue decomposing agent with biogas output synergistic effect and application thereof

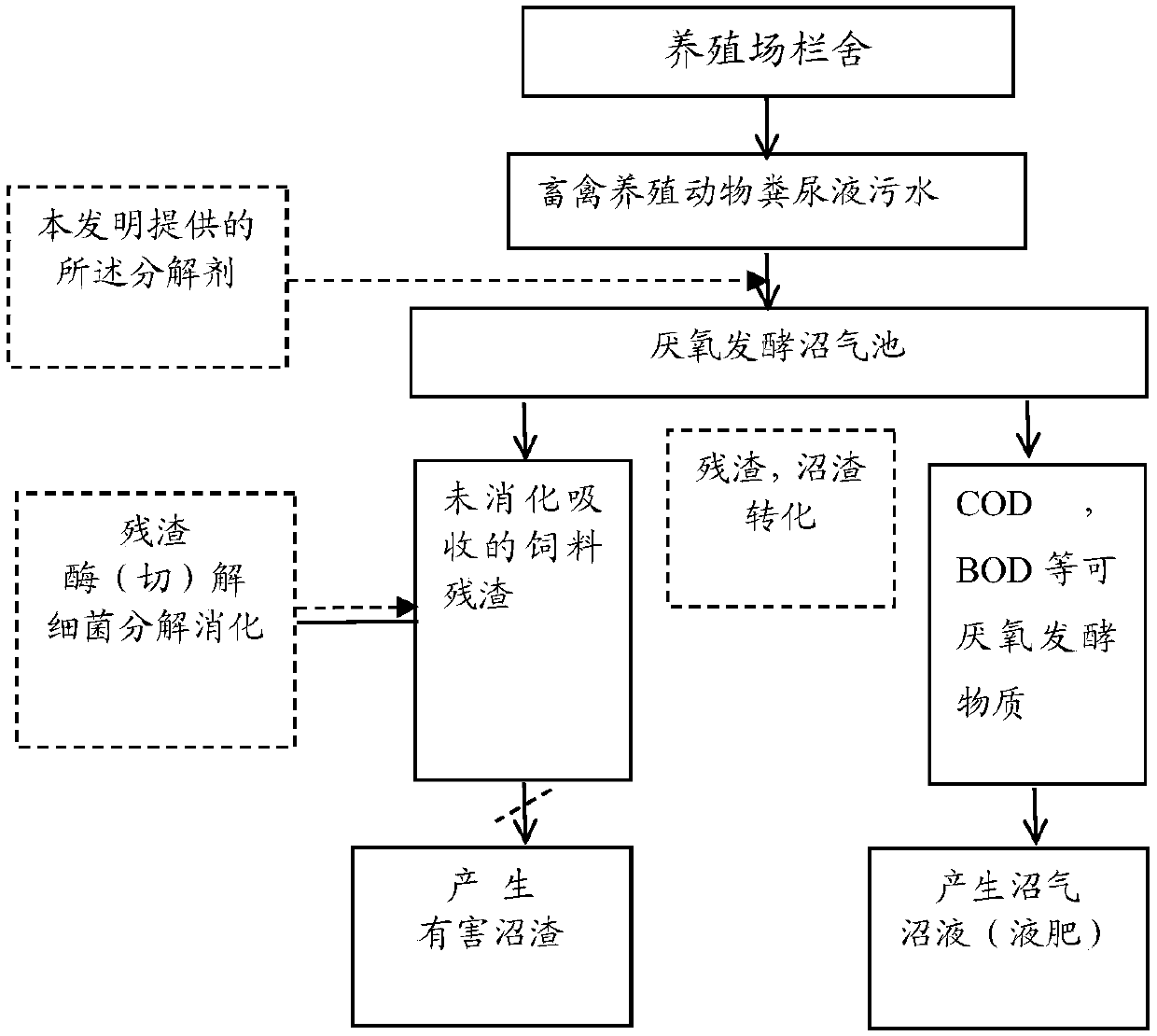

A technology of synergistic effect and decomposer, applied in microorganism-based methods, immobilized on/in organic carriers, biochemical equipment and methods, etc. Fermentation efficiency and service life and other issues, to achieve the effect of complete decomposition, shorten the fermentation cycle, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the present invention, the preparation method of the biogas residue decomposing agent with synergistic effect on biogas production preferably includes the following steps:

[0027] 1) mixing cellulase and xylanase to obtain a compound enzyme;

[0028] 2) mixing the compounded enzyme in the step 1) with Bacillus subtilis and Bacillus licheniformis to obtain an enzyme-bacteria complex;

[0029] 3) Mixing the enzyme-bacteria complex in the step 2) with the carrier to obtain a biogas residue decomposing agent with synergistic effects on biogas production.

[0030] In the present invention, the mixing method is not particularly limited, and a mixing scheme well known to those skilled in the art can be used.

[0031] The invention provides the application of the biogas residue decomposer with biogas production synergistic effect in improving biogas production and / or biogas residue degradation efficiency in biogas fermentation.

[0032]In the present invention, the raw ma...

Embodiment 1

[0036] Bacillus licheniformis powder and Bacillus subtilis powder purchased from Shandong Gaolong Biotechnology Co., Ltd. were mixed with β-1,4-glucan-4-glucan hydrolase, β-1,4-endolog Mix glycanase and β-xylosidase, then add defatted rice bran and mix thoroughly, so that the content of each component is 2.0 for the activity of β-1,4-glucan-4-glucanohydrolase per gram of defatted rice bran ×10 5 U, β-1,4-endoxylanase, β-xylosidase is 1.0×10 5 U, the number of viable bacteria of Bacillus subtilis is 20 billion CFU, and the number of viable bacteria of Bacillus licheniformis is 10 billion CFU, and a biogas residue decomposing agent with synergistic effect on biogas production is obtained.

Embodiment 2

[0038] The original powder of Bacillus licheniformis and Bacillus subtilis purchased from Shandong Gaolong Biotechnology Co., Ltd. were mixed with β-1,4-glucan-4-glucanohydrolase and α-L-arabinosidase, Then add defatted rice bran and mix thoroughly so that the content of each component is β-1,4-glucan-4-glucan hydrolase activity per gram of defatted rice bran is 1.8×10 5 U, α-L-arabinosidase activity is 0.9×10 5 U, the number of viable bacteria of Bacillus subtilis is 18 billion CFU, and the number of viable bacteria of Bacillus licheniformis is 9 billion CFU, and a biogas residue decomposing agent with synergistic effect on biogas production is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com