Catalyst with ruthenium-loaded titanium dioxide hollow spheres embedded with silicon dioxide nanoparticles and preparation method and application of catalyst

A technology of titanium dioxide and silicon dioxide, which is applied in the field of ruthenium-supported titanium dioxide hollow sphere embedded silicon dioxide nanoparticle catalyst and its preparation, can solve the problems of high reaction temperature, hydrogen pressure, complex degradation products, and low utilization rate, and achieve improved Utilization rate, simple preparation method, and high reaction safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

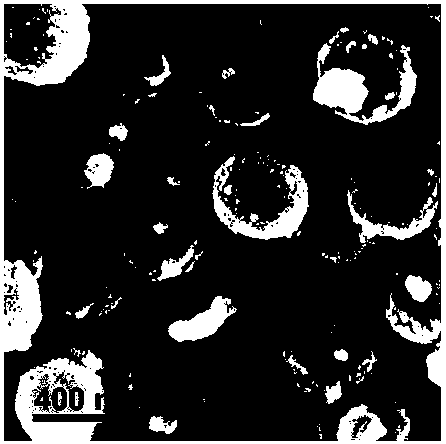

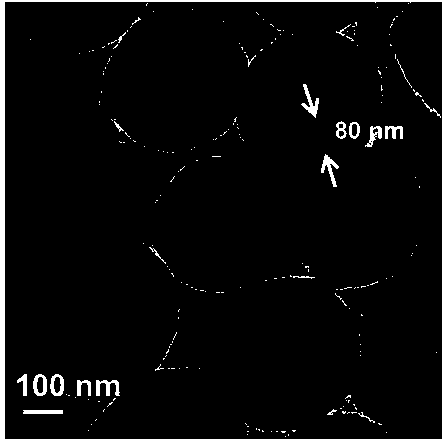

Image

Examples

Embodiment 1

[0027] Put 3.5ml of ammonia water (25% concentration), 10ml of deionized water and 58.5ml of absolute ethanol into the container, stir for 30 minutes to obtain a mixed solution, then add 5.6ml of tetraethyl silicate to the mixed solution and continue to stir for 1 hour , and then filtered the solution to obtain a filter cake that was washed three times with water and ethanol, and dried at 60°C for 12 hours to obtain SiO 2 Microspheres; Weigh 0.8 g of SiO obtained 2 The microspheres were dispersed into 97.4 ml absolute ethanol solvent by ultrasonication for 30 minutes to obtain SiO 2For the suspension of microspheres, add 1.0 g cetylamine and 2 ml ammonia water to the suspension and stir for 30 minutes, add 2.2 ml tetraisopropyl titanate to the solution, continue stirring for 2 hours, stop stirring, and age 12 hours, and then filtered, the filter cake was washed three times with deionized water and then dried at 60° C. for 12 hours to obtain solid powder titanium dioxide-coate...

Embodiment 2

[0030] Put 3.5ml of ammonia water (28% concentration), 20ml of deionized water and 80ml of absolute ethanol into the container, stir for 30 minutes to obtain a mixed solution, then add 8.6ml of tetraethyl silicate to the mixed solution and continue to stir for 1 hour. Filter the solution again, and the filter cake obtained is washed three times with water and ethanol respectively, and dried at 80°C for 6 hours to obtain SiO 2 Microspheres; 0.5 g of SiO obtained by weighing 2 The microspheres were dispersed into 97.4 ml absolute ethanol solvent by ultrasonication for 30 minutes to obtain SiO 2 For the suspension of microspheres, add 0.5 g cetylamine and 1 ml ammonia water to the suspension and stir for 30 minutes, add 1.2 ml tetraisopropyl titanate to the solution, continue stirring for 2 hours, stop stirring, and age 12 hours, and then filtered, the filter cake was washed three times with deionized water and then dried at 60° C. for 12 hours to obtain solid powder titanium di...

Embodiment 3

[0032] Put 3.5ml of ammonia water (concentration 28%), 10ml of deionized water and 58.5ml of absolute ethanol into the container, stir for 30 minutes to obtain a mixed solution, then add 3.6ml of tetraethyl silicate to the mixed solution and continue to stir for 1 hour , and then filtered the solution to obtain a filter cake that was washed three times with water and ethanol, and dried at 40°C for 12 hours to obtain SiO 2 Microspheres; Weigh 0.4 g of SiO obtained 2 The microspheres were dispersed into 97.4 ml absolute ethanol solvent by ultrasonication for 30 minutes to obtain SiO 2 For the suspension of microspheres, add 1.0 g cetylamine and 2 ml ammonia water to the suspension and stir for 30 minutes, add 2.2 ml tetraisopropyl titanate to the solution, continue stirring for 2 hours, stop stirring, and age 12 hours, and then filtered, the filter cake was washed three times with deionized water and then dried at 60° C. for 12 hours to obtain solid powder titanium dioxide-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com