Anti-aging-cracking plastic flooring and preparation method thereof

A plastic floor, anti-aging technology, applied in the field of anti-aging cracking plastic floor and its preparation, can solve the problems of poor anti-aging cracking performance, etc. The effect of heat and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] An anti-aging cracking plastic floor, made of the following raw materials (kg): ultra-high molecular weight polyethylene 51, poly-p-phenylene terephthalamide 26, sepiolite wool 17, cyclohexanedicarboxylic acid dicarboxylate Alkyl ester 12, behenic acid amide 5, styrene-butadiene block copolymer 19, floc lignin fiber 11, silicon carbide whiskers 10, chalk powder 16, methyl 3-mercaptopropionate 5, hard Cadmium fatty acid 2, barium stearate 1.5, tridecyl trimellitate 13.

[0015] A preparation method for anti-aging cracking plastic floor, comprising the following steps:

[0016] (1) Add ultra-high molecular weight polyethylene, poly-p-phenylene terephthalamide, styrene-butadiene block copolymer, tridecyl trimellitate, and methyl 3-mercaptopropionate to a high-speed mixer Inside, mix at a high speed of 55-75°C for 10-15 minutes, then add cadmium stearate, barium stearate, behenic acid amide, sepiolite wool, flocculent lignin fiber, silicon carbide whiskers, chalk powder ,...

Embodiment 2

[0021] An anti-aging cracking plastic floor, made of the following raw materials by weight (kg): ultra-high molecular weight polyethylene 59, poly-p-phenylene terephthalamide 34, sepiolite wool 23, cyclohexanedicarboxylic acid dicarboxylate Alkyl ester 16, behenic acid amide 6, styrene-butadiene block copolymer 24, floc lignin fiber 14, silicon carbide whisker 12, chalk powder 19, methyl 3-mercaptopropionate 7, hard Cadmium stearate 2.5, Barium stearate 2, Tridecyl trimellitate 17.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] An anti-aging cracking plastic floor, made of the following raw materials by weight (kg): ultra-high molecular weight polyethylene 66, poly-p-phenylene terephthalamide 40, sepiolite wool 29, cyclohexanedicarboxylic acid dicarboxylate Alkyl ester 19, behenic acid amide 7, styrene-butadiene block copolymer 33, floc lignin fiber 17, silicon carbide whiskers 15, chalk powder 23, methyl 3-mercaptopropionate 10, hard Cadmium fatty acid 3, barium stearate 2.5, tridecyl trimellitate 21.

[0025] The preparation method is the same as in Example 1.

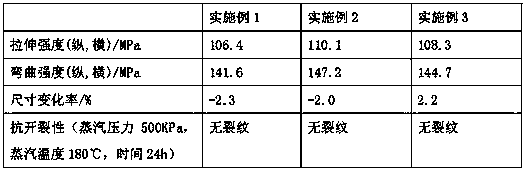

[0026] The performance test results of the plastic floor made by the above-mentioned embodiments 1-3 are shown in the table below:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com