Novel electrical cabinet

A power cabinet, a new type of technology, applied in the substation/distribution device shell, substation/switchgear cooling/ventilation, coating, etc., can solve the problem of reducing the load-bearing capacity of the partition board, affecting the installation of large equipment in the power cabinet, and reducing the use Life and other issues, to achieve good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

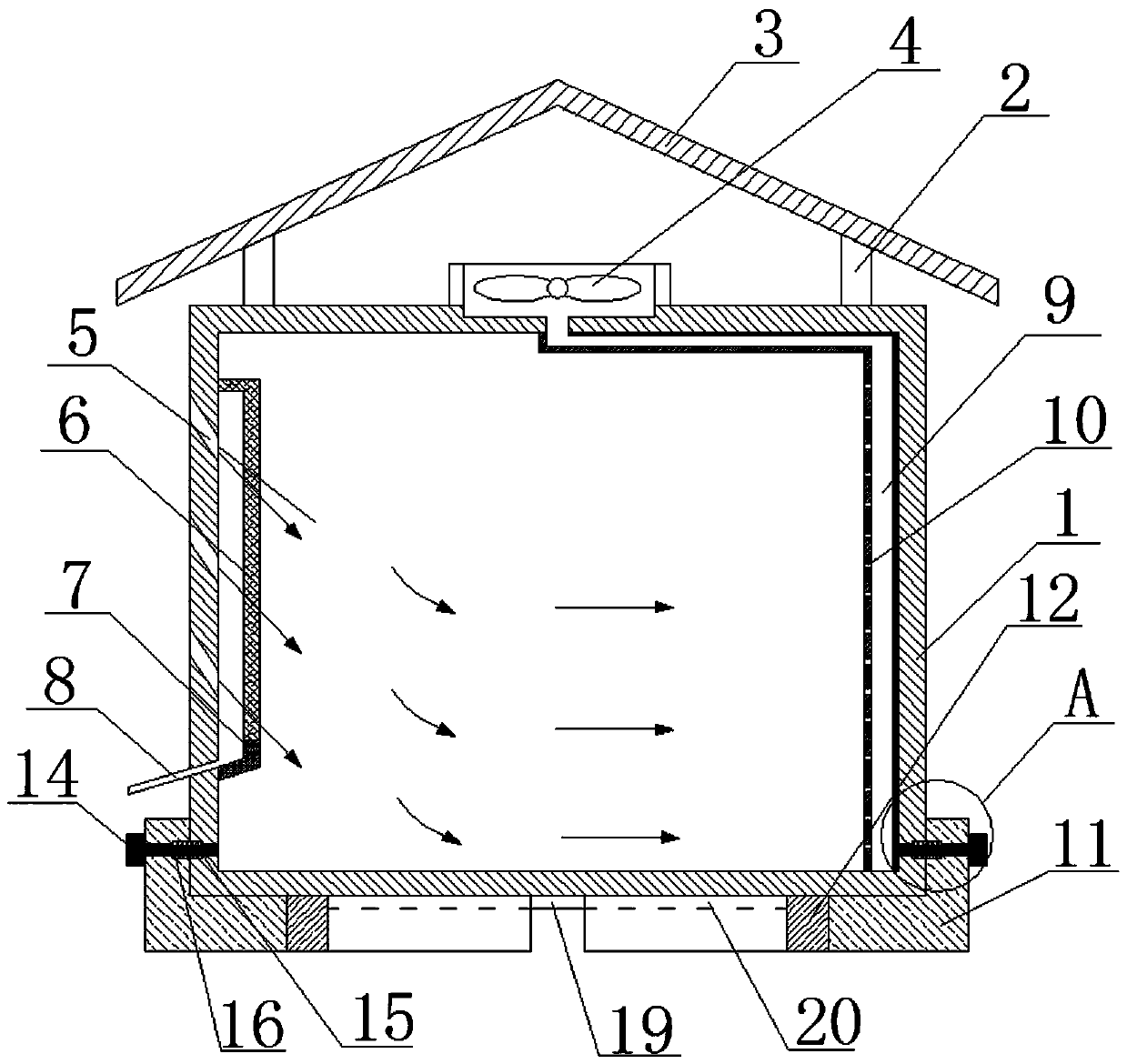

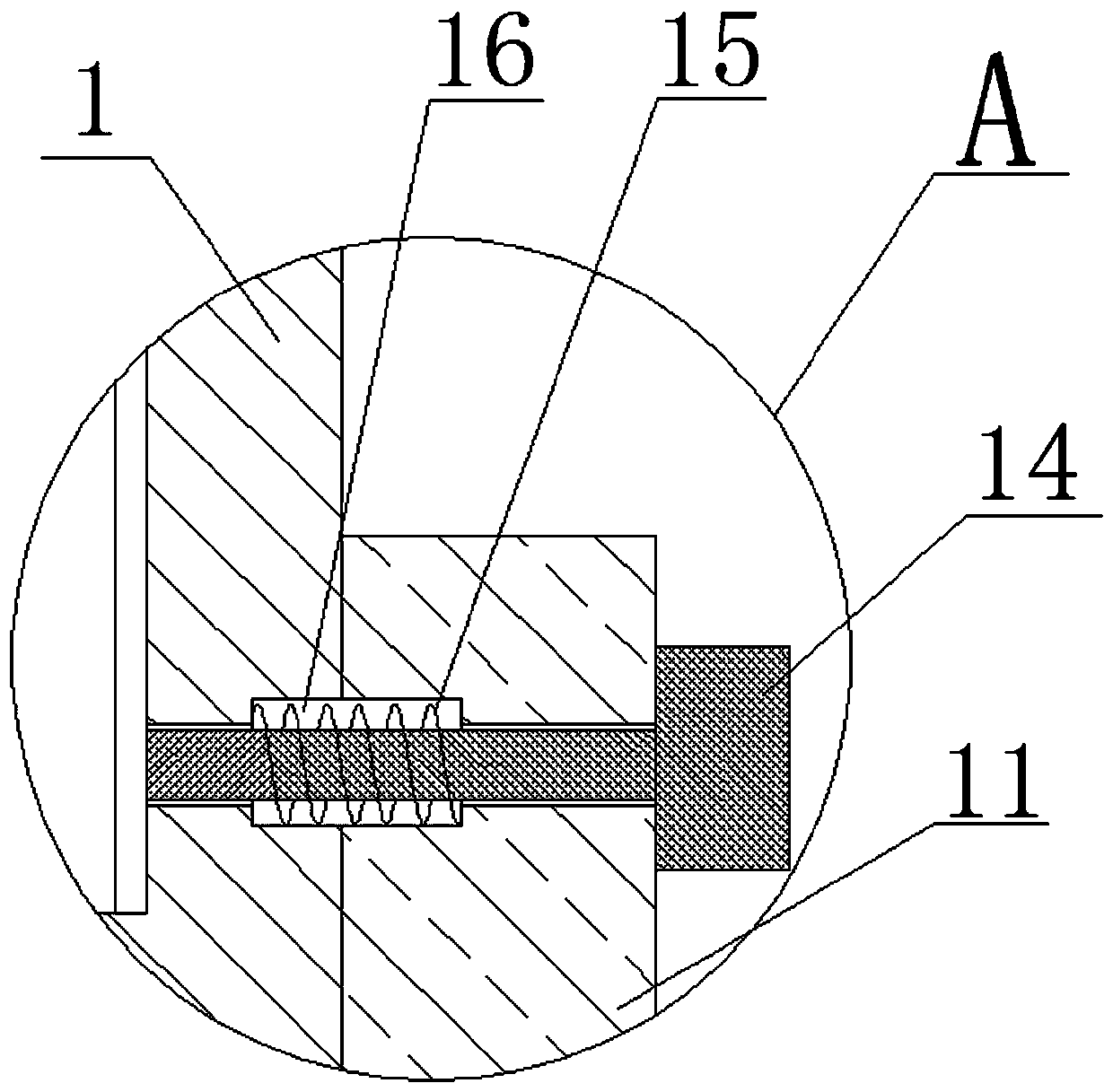

[0033] Such as figure 1 , figure 2 and image 3 As shown, a new type of power cabinet includes a cabinet body 1. The top of the cabinet body 1 is connected to the top cover 3 through the support rod 2. The function of the top cover is mainly to prevent rain and sunscreen; Exhaust fan 4; inwardly inclined ventilation holes 5 are provided on the side wall of the cabinet body, and a filter cover 6 is provided at the corresponding position on the inner wall of the cabinet body 1 and the ventilation hole 5, and a dust accumulation tank 7 is provided at the bottom of the filter cover 1 6, wherein the dust accumulation tank 7 is connected The bottom is provided with a drainage pipe 8, and the drainage pipe 8 passes through the side wall of the cabinet body 1 and extends out of the cabinet.

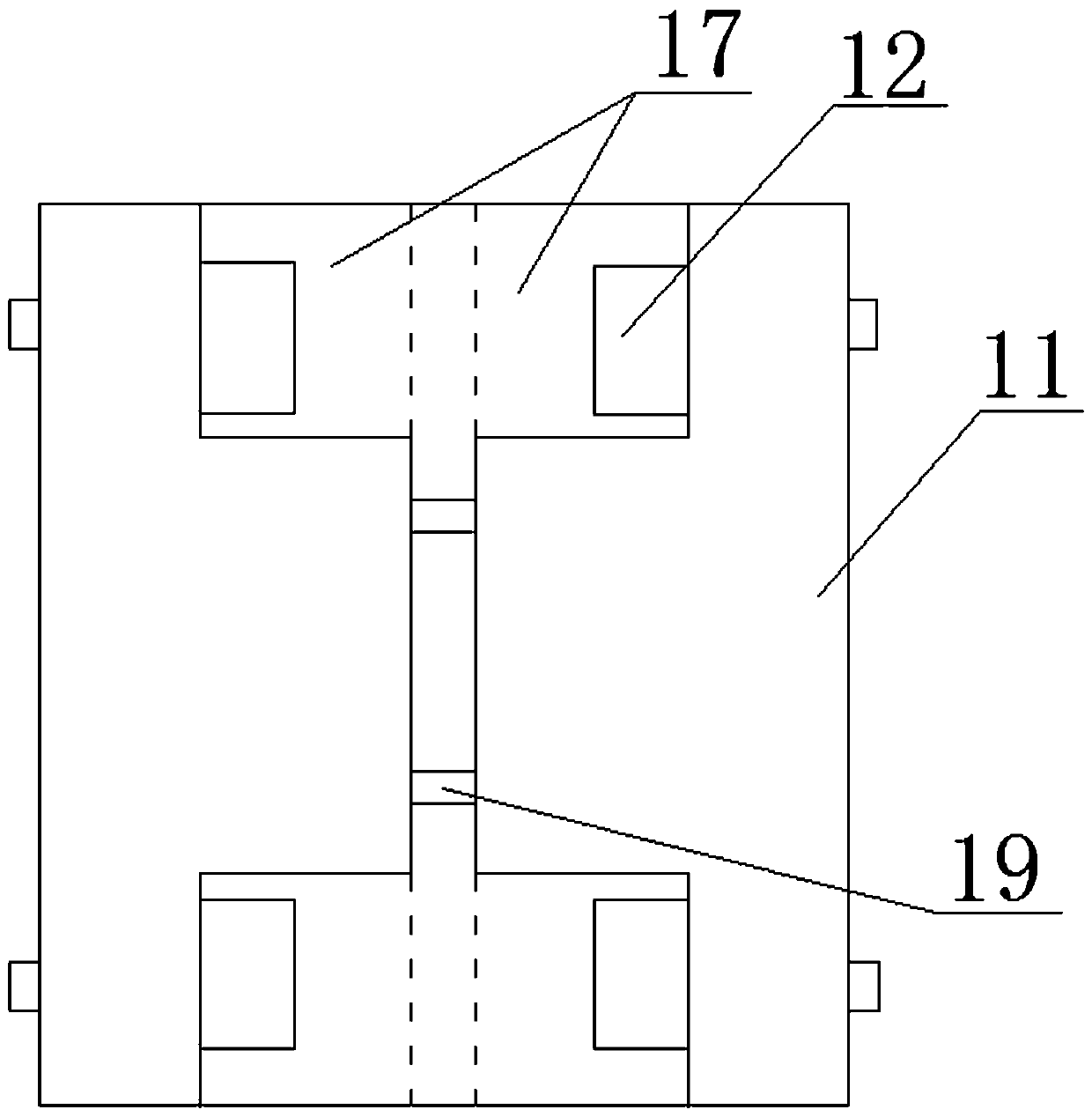

[0034] The interior of the side wall corresponding to the cabinet 1 and the ventilation hole 5 is provided with an exhaust channel 9. The exhaust channel 9 is a rectangular parallelepiped stru...

Embodiment 2

[0041] Embodiment 2 is basically the same as Embodiment 1, the difference is: as Figure 4 As shown, filter cover 2 18 is set on the top of exhaust fan 4, and is used to filter dust; In addition, waterproof cover 13 is set on the cabinet body 1 outer wall corresponding to ventilation hole 5, and is used to prevent rainwater from entering the cabinet body, which is safer.

[0042] Wherein the outer surface of the cabinet 1 is sprayed with a thermally conductive insulating coating, and the thermally conductive insulating coating is made of the following raw materials in parts by weight: 35 parts of acrylic emulsion, 15 parts of epoxy resin, 5 parts of nano-magnesium oxide, 8 parts of silicon nitride, and 5 parts of rosin powder 12 parts of nitrile rubber powder, 5 parts of polyethylene glycol octyl phenyl ether, 2 parts of sodium lignosulfonate, 20 parts of solvent, 6 parts of water and 3 parts of silicone dispersant.

[0043] The solvent is a mixture of ethylene glycol and xyle...

Embodiment 3

[0046] Embodiment 3 has the same structure as Embodiment 1, the difference is:

[0047] Wherein the outer surface of the cabinet 1 is sprayed with a thermally conductive insulating coating, and the thermally conductive insulating coating is made of the following raw materials in parts by weight: 36 parts of acrylic emulsion, 16 parts of epoxy resin, 6 parts of nano-magnesium oxide, 7 parts of silicon nitride, and 6 parts of rosin powder 14 parts of nitrile rubber powder, 4 parts of polyethylene glycol octyl phenyl ether, 3 parts of sodium lignosulfonate, 18 parts of solvent, 7 parts of water and 2.5 parts of silicone dispersant.

[0048] The solvent is a mixture of ethylene glycol and xylene in a weight ratio of 1:2.

[0049] The preparation method of the thermally conductive insulating coating comprises the following steps: after dispersing acrylic emulsion, epoxy resin, solvent, polyethylene glycol octylphenyl ether, water, sodium lignosulfonate and dispersant at a low speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com