Preparation method of engineering thermal-insulation material based on thermochemical energy storage

A technology of thermal insulation materials and energy storage materials, which is applied in the field of engineering thermal insulation materials, can solve the problems of complex preparation methods, degradation of thermal insulation performance, and high cost, and achieve the effects of promoting effective compounding, excellent thermal insulation performance, and small seasonal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

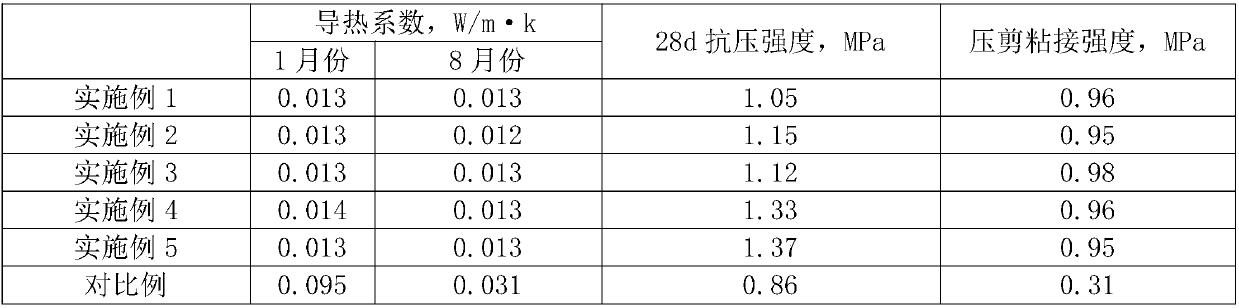

Examples

Embodiment 1

[0028] A method for preparing an engineering thermal insulation material based on thermochemical energy storage, comprising the following steps:

[0029] (1) Mix zeolite molecular sieve and distilled water, ultrasonicate at 1000W for 30min, sonicate, stand still for 5h, centrifuge, dry, and seal and store; wherein, the mass ratio of distilled water to zeolite powder molecular sieve is 1.1:1; the drying temperature is 150 ℃, drying time is 10h;

[0030] (2) Anhydrous magnesium sulfate and distilled water are mixed and stirred until the solid dissolves to obtain a magnesium sulfate solution; wherein, the mass ratio of the distilled water and anhydrous magnesium sulfate is 18:1;

[0031] (3) adding the zeolite molecular sieve treated in step (1) into the magnesium sulfate solution prepared in step (2) and impregnating for 12 hours, after the impregnation is completed, drying at 120° C., sealing and storing, and obtaining a thermochemical energy storage material; wherein, The mas...

Embodiment 2

[0036] A method for preparing an engineering thermal insulation material based on thermochemical energy storage, comprising the following steps:

[0037] (1) Mix zeolite molecular sieve and distilled water, ultrasonicate at 1000W for 30min, sonicate, stand still for 7h, centrifuge, dry, and seal and store; wherein, the mass ratio of distilled water to zeolite powder molecular sieve is 3:1; the drying temperature is 300 ℃, drying time is 10h;

[0038] (2) Anhydrous magnesium sulfate and distilled water are mixed and stirred until the solid is dissolved to obtain a magnesium sulfate solution; wherein, the mass ratio of the distilled water and anhydrous magnesium sulfate is 23:1;

[0039] (3) adding the zeolite molecular sieve treated in step (1) into the magnesium sulfate solution prepared in step (2) and impregnating for 15 hours, after the impregnation is completed, drying at 300° C., sealing and storing, and obtaining a thermochemical energy storage material; wherein, The ma...

Embodiment 3

[0044] A method for preparing an engineering thermal insulation material based on thermochemical energy storage, comprising the following steps:

[0045] (1) Mix zeolite molecular sieves with distilled water, ultrasonicate at 1000W for 30min, sonicate, stand still for 5.5h, centrifuge, dry, and seal and store; wherein, the mass ratio of distilled water to zeolite powder molecular sieves is 1.5:1; the drying temperature is 180℃, drying time is 7h;

[0046] (2) Anhydrous magnesium sulfate and distilled water are mixed and stirred until the solid is dissolved to obtain a magnesium sulfate solution; wherein, the mass ratio of the distilled water and anhydrous magnesium sulfate is 19:1;

[0047](3) adding the zeolite molecular sieve treated in step (1) into the magnesium sulfate solution prepared in step (2) and dipping for 13 hours, after the dipping is completed, drying at 150° C., sealing and storing, to obtain a thermochemical energy storage material; wherein, The mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com