A kind of vegetable protein adhesive and its preparation method and application

A plant protein and adhesive technology, which is applied in the preparation of animal glue or gelatin, protein adhesives, adhesives, etc., can solve the problems of pollution, unrealized green and renewable soybean protein adhesives, and achieve Easy to use, low price, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

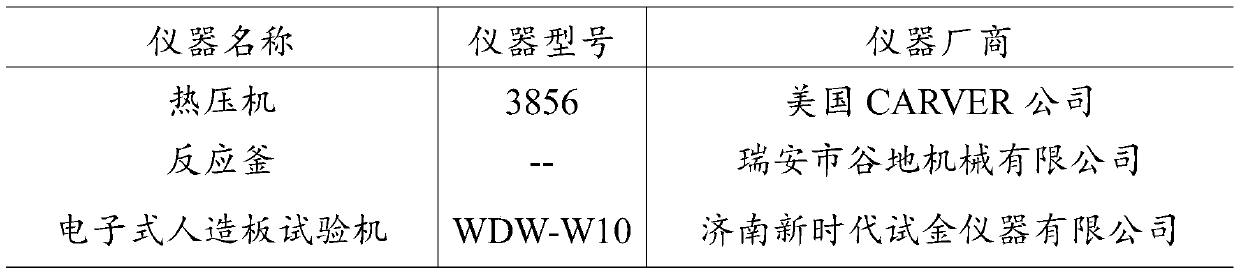

Image

Examples

preparation example Construction

[0037] In the present invention, the preparation method of the glucose-lignin resin crosslinking agent preferably comprises the following steps:

[0038] Hydrolyzing the aqueous glucose solution under the catalysis of an acid catalyst to obtain a hydrolyzate system;

[0039] adjusting the pH value of the hydrolyzate system to 10-13 to obtain an alkaline hydrolyzate system;

[0040] The alkaline hydrolyzate system is polymerized with lignin to obtain a glucose-lignin resin cross-linking agent.

[0041] In the invention, the aqueous glucose solution is hydrolyzed under the catalysis of an acidic catalyst to obtain a hydrolyzed product system. In the present invention, the glucose is commercially available glucose well known to those skilled in the art. In the present invention, the acidic catalyst is preferably one or more of hydrochloric acid, sulfuric acid, nitric acid, hydrohalic acid and oxalic acid. The present invention does not have any special requirements on the conc...

Embodiment 1

[0069] A vegetable protein adhesive, based on the total mass of the adhesive raw material as 100%, each component and mass percentage in the raw material are as follows:

[0070]

[0071]

[0072] A preparation method of vegetable protein adhesive, the specific steps of the method are as follows:

[0073] (1) Put 300 kg of glucose and 100 kg of water into the reactor, mechanically stir at 80r / min for 10 minutes, then heat up to 60°C, add 5 kg of sulfuric acid, gradually heat up to 90°C and keep it warm for 3 hours, then cool down to 80°C, use 30% sodium hydroxide aqueous solution to adjust the pH value to 12, add 35 kg of enzymatic lignin, and carry out polymerization reaction. After the viscosity of the polymerized product (25°C) reaches 200MPa·s, cool down to 30°C, and discharge , to obtain the glucose-lignin resin crosslinking agent.

[0074] (2) 200 kilograms of defatted soy flour, 600 kilograms of water, 80 kilograms of guanidine hydrochloride and 5 kilograms of ma...

Embodiment 2

[0078] A vegetable protein adhesive, based on the total mass of the adhesive raw material as 100%, each component and mass percentage in the raw material are as follows:

[0079]

[0080] (1) Put 300 kg of glucose and 100 kg of water into the reaction kettle, stir mechanically at 80r / min for 10 minutes, then heat up to 60°C, add 5 kg of sulfuric acid, gradually heat up to 95°C and keep it warm for 1 hour, then cool down to 85°C, use 30% sodium hydroxide aqueous solution to adjust the pH value to 13, add 35 kg of alkali lignin, and carry out polymerization reaction. When the viscosity of the polymerization product (25°C) reaches 250MPa·s, cool down to 30°C, and discharge to obtain the obtained The above-mentioned cross-linking agent (glucose-lignin resin).

[0081] (2) 400 kilograms of defatted peanut powder, 450 kilograms of water, 20 kilograms of sodium dodecylbenzenesulfonate and 30 kilograms of mass concentration of 30% potassium hydroxide aqueous solution are dropped into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com