NiCl2-GICs composite anode material for thermal battery and its preparation method

A composite positive electrode material and thermal battery technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient utilization, poor safety, high resistivity, etc., and achieve the effect of high atomic utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

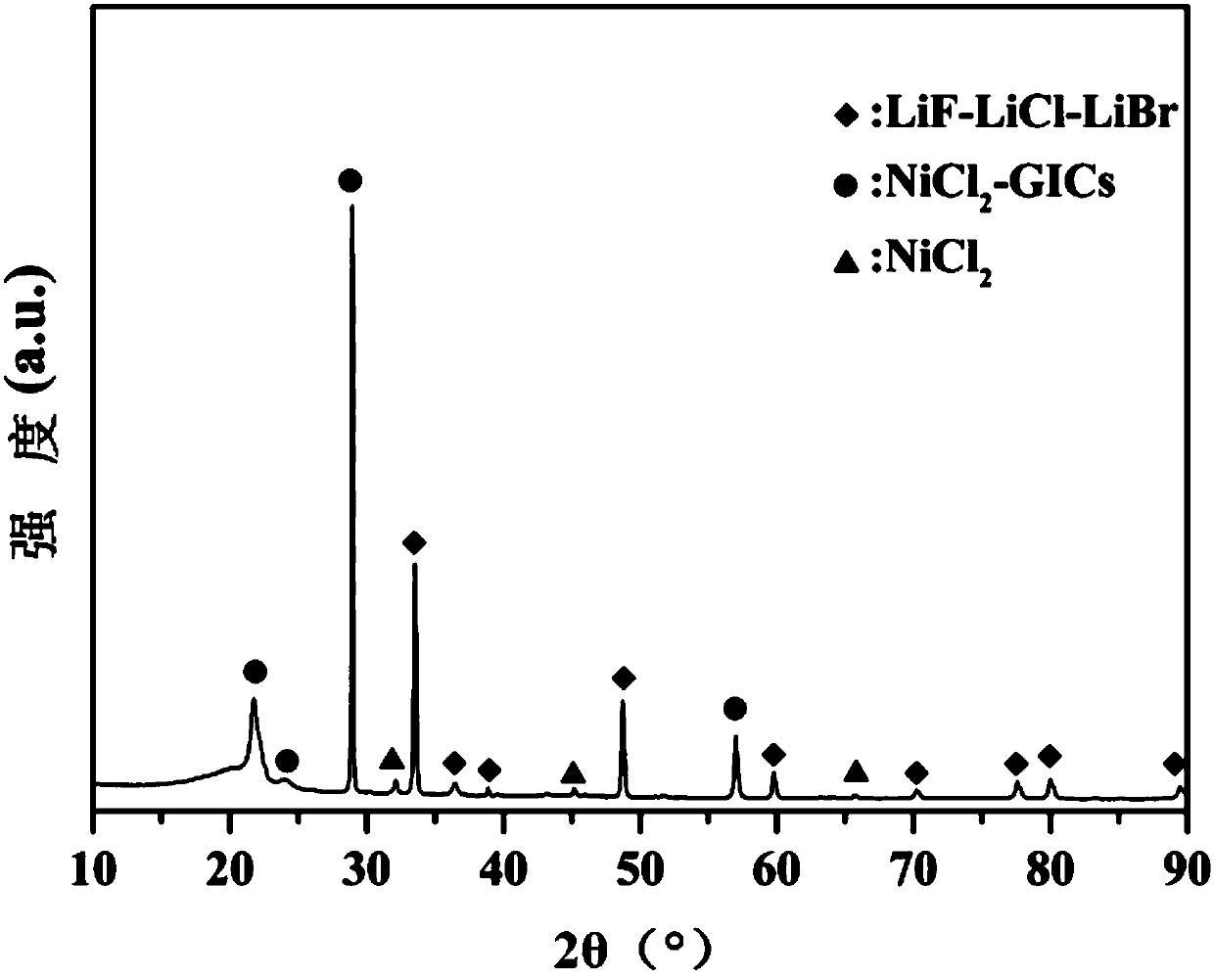

Embodiment 1

[0031] According to the target product NiCl 2 - The ratio of each component in the GICs composite cathode material is used to calculate the amount of each raw material. Weigh 153NiCl in the present embodiment 2 (the proportion of the substance is 10%), 84g pyrolytic graphite (the proportion of the substance is 70%), 120g LiF-LiCl-LiBr eutectic salt (the proportion of the substance is 20%). In an environment with a dew point lower than -40°C, the three raw materials were placed in a blast drying oven for 2 hours at a drying temperature of 120°C. 153g NiCl2 , put 84g of pyrolytic graphite and 60g of LiF-LiCl-LiBr eutectic salt into an agate mortar, grind them evenly, put them into a sealed stainless steel tank, bake them at 500°C for 12h, and cool them down to room temperature naturally. The precursor was obtained after ball milling. Mix the precursor and 60g LiF-LiCl-LiBr eutectic salt evenly and place it in an atmosphere protection furnace, rapidly raise the temperature to ...

Embodiment 2

[0033] According to the target product NiCl 2 - The ratio of each component in the GICs composite cathode material is used to calculate the amount of each raw material. Weigh 153NiCl in the present embodiment 2 (the amount of the substance is 10%), 84g natural flake graphite (the amount of the substance is 70%), 192g LiCl-LiBr-KBr eutectic salt (the amount of the substance is 20%). In an environment with a dew point lower than -40°C, the three raw materials were placed in a blast drying oven for 2 hours at a drying temperature of 120°C. 153g NiCl 2 , 84g of natural flake graphite and 96g of LiF-LiCl-LiBr eutectic salt were placed in an agate mortar, ground evenly and put into a sealed stainless steel tank, roasted at 400°C for 24h, cooled naturally to room temperature, and ball-milled the block product The precursor is obtained after pulverization. The precursor and 96g LiF-LiCl-LiBr eutectic salt were mixed evenly and then placed in the atmosphere protection furnace. Unde...

Embodiment 3

[0035] According to the target product NiCl 2 - The ratio of each component in the GICs composite cathode material is used to calculate the amount of each raw material. Weigh 230NiCl in the present embodiment 2 (The amount of substance is 15%), 66g graphitized carbon fiber (the amount of substance is 55%), 168g LiCl-KCl eutectic salt (the amount of substance is 30%). In an environment with a dew point lower than -40°C, the three raw materials were placed in a blast drying oven for 2 hours at a drying temperature of 120°C. 230g NiCl 2 , 66g of graphitized carbon fiber and 84g of LiCl-KCl eutectic salt were placed in an agate mortar, ground evenly, put into a sealed stainless steel tank, roasted at 400°C for 12h, cooled naturally to room temperature, and ball milled the blocky product Then get the precursor. The precursor and 84g LiF-LiCl-LiBr eutectic salt were mixed evenly and then placed in the atmosphere protection furnace. Under the protection of argon, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com