Preparation method of WSe2 (tungsten diselenide) thin film material and application in photocatalytic reduction of CO2 (carbon dioxide)

A tungsten diselenide, photocatalytic technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of large particle size, no photocatalytic activity, and high calcination temperature, and achieve high recycling rate, good photoelectric performance, The effect of high material purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

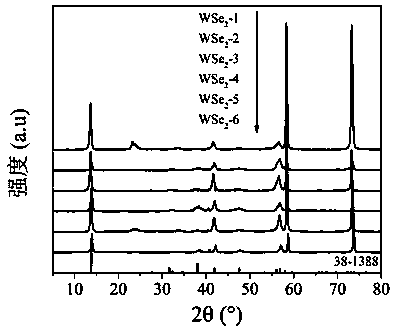

Embodiment 1

[0026] Dissolve 1.0 g of polyvinylpyrrolidone and 1.0 g of citric acid in 20 mL of deionized water, weigh 1 g of selenium powder, add to the above solution, mix well, and dry in an oven at 60 °C for later use. will be 10 cm 2 The metal tungsten sheet was washed with 30 mL of acetone, absolute ethanol, and deionized water respectively, and then drained. Then soak in 100mL, 0.5 mol / L dilute hydrochloric acid solution for 30min, rinse with deionized water, dry and set aside. The prepared selenium powder is placed on the air inlet side, the treated metal tungsten sheet is placed on the gas outlet side, and both are placed in the constant temperature zone of the tube furnace. Before the reaction, high-purity nitrogen gas was introduced in advance to remove the air. Then start heating to raise the temperature, and at the same time switch the gas into hydrogen / nitrogen mixed gas, wherein the hydrogen content is 20% (V / V). After reaching 600 °C, it was kept for 8 h, and finally co...

Embodiment 2

[0028]Dissolve 0.1 g of polyvinylpyrrolidone and 1.0 g of citric acid in 10 mL of deionized water, weigh 1 g of selenium powder, add to the above solution, mix well, and dry in an oven at 60 °C for later use. Wash the metal tungsten sheet with 30 mL of acetone, absolute ethanol, and deionized water respectively, and drain. Then soak in 100mL, 0.5 mol / L dilute hydrochloric acid solution for 30 minutes, rinse with deionized water, dry and set aside. The prepared selenium powder is placed on the air inlet side, the treated metal tungsten sheet is placed on the gas outlet side, and both are placed in the constant temperature zone of the tube furnace. Before the reaction, high-purity argon was passed through to remove the air. Then start to heat up the temperature, and at the same time switch the gas into hydrogen / argon gas mixture, wherein the hydrogen content is 0.5% (V / V). After reaching 900 °C, it was kept for 2 h, and finally cooled naturally. After the temperature of the t...

Embodiment 3

[0030] Dissolve 1.0 g of polyvinylpyrrolidone and 0.1 g of citric acid in 10 mL of deionized water, weigh 1 g of selenium powder, add to the above solution, mix well, and dry in an oven at 60 °C for later use. Wash the metal tungsten sheet with 30 mL of acetone, absolute ethanol, and deionized water respectively, and drain. Then soak in 100mL, 0.5 mol / L dilute hydrochloric acid solution for 30 minutes, rinse with deionized water, dry and set aside. The prepared selenium powder is placed on the air inlet side, the treated metal tungsten sheet is placed on the gas outlet side, and both are placed in the constant temperature zone of the tube furnace. Before the reaction, high-purity nitrogen gas was introduced in advance to remove the air. Then start heating to raise the temperature, and at the same time switch the feeding gas to hydrogen / nitrogen mixed gas, wherein the hydrogen content is 0.5% (V / V). After reaching 900 °C, it was kept for 2 h, and finally cooled naturally. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com